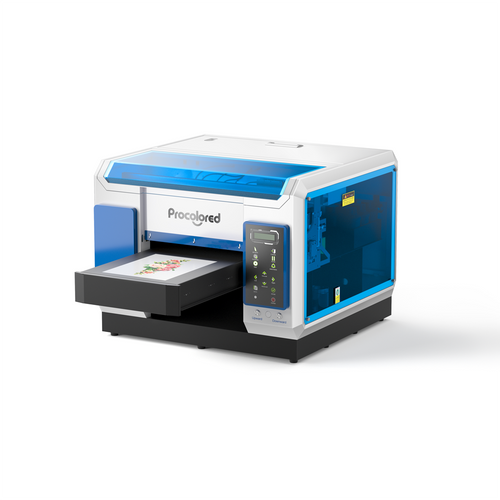

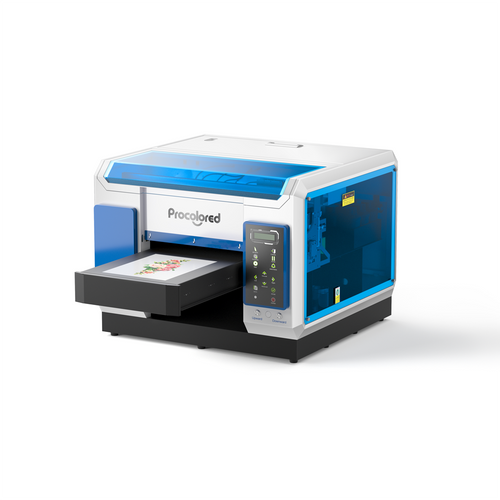

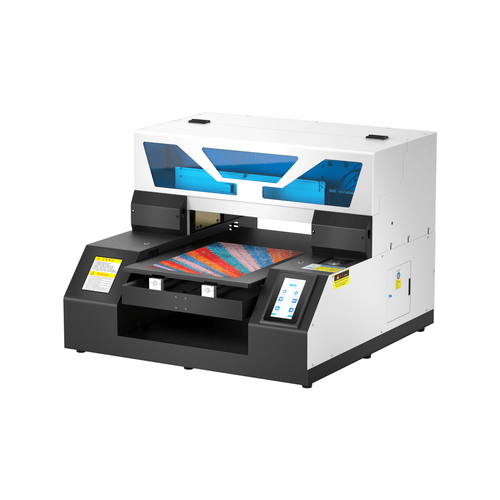

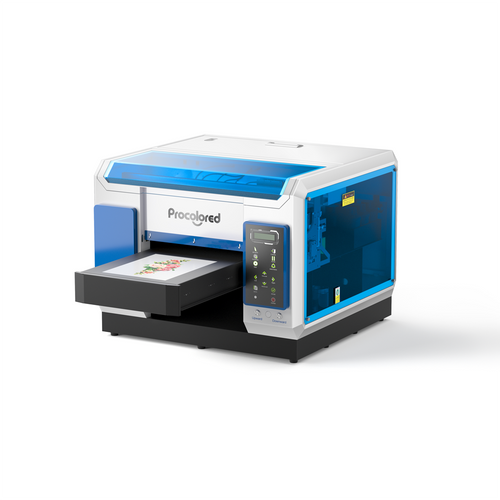

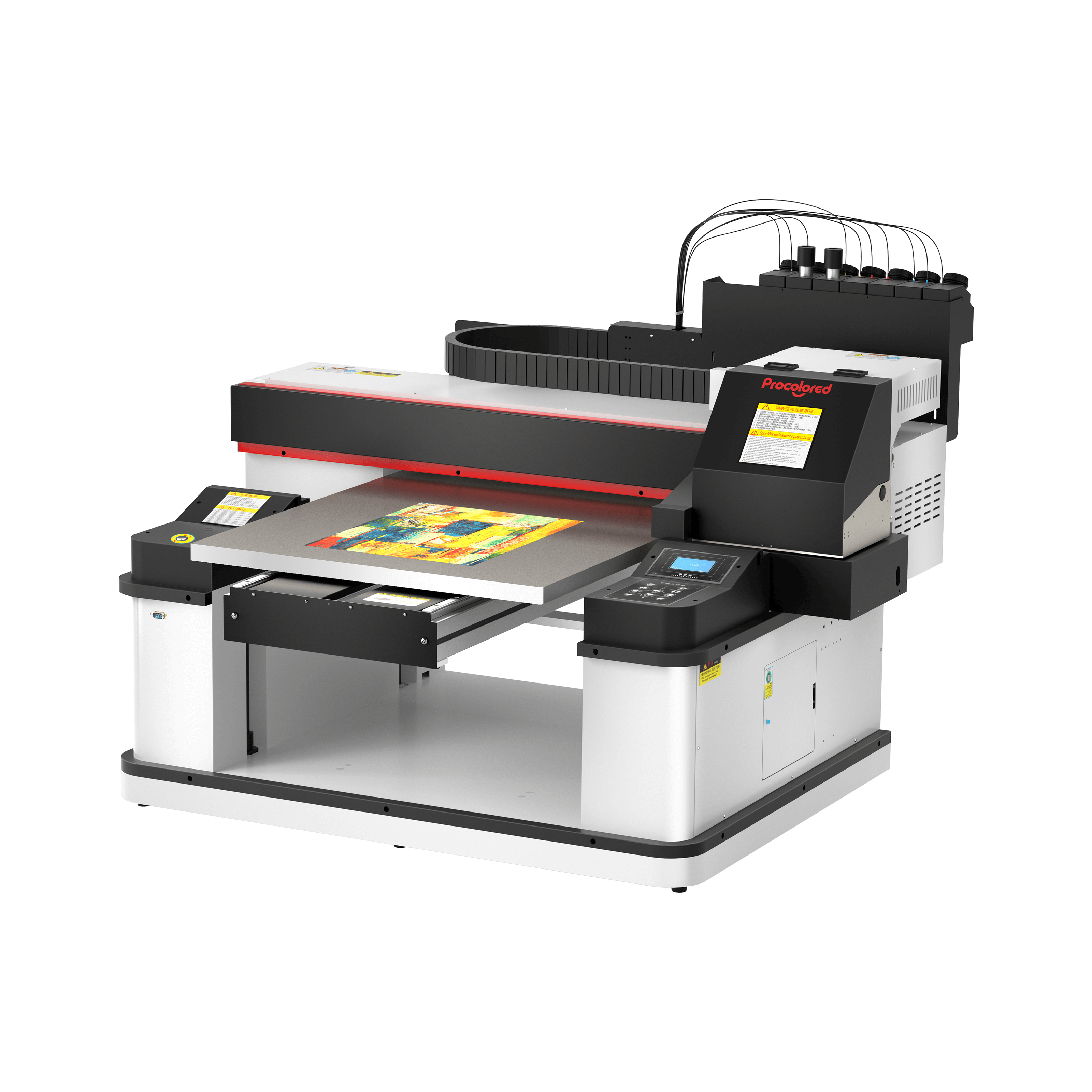

UV DTF Printer

As the name itself shows, UV DTF printer in some ways combines the functions of UV printer (Ultro Violet printer) and DTF printer (Direct to Film printer) together.

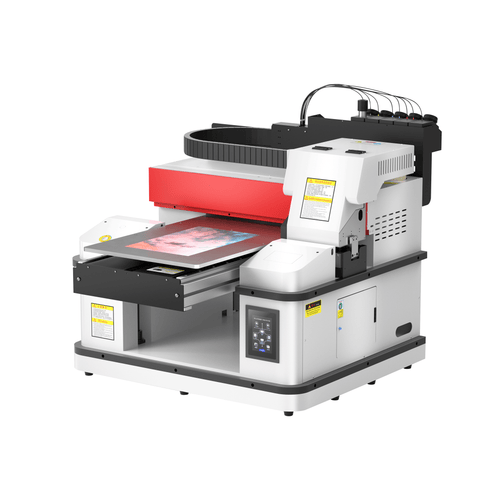

Like DTF printing, UV DTF printing first prints out graphics on films. And right after, the built-in UV lamps will cure the printed ink instantly as other UV printing machines do. Then the UV DTF machine will automatically laminate the films and printings and finally make it into UV DTF transfers - crystal stickers, which can turn UV DTF printer into a printer on wood, metal, acrylic and so forth materials.

Yet UV DTF printer can not be applied on fabrics.

For recommendations on such application, please move to: A3 DTF printer, best DTF printer.

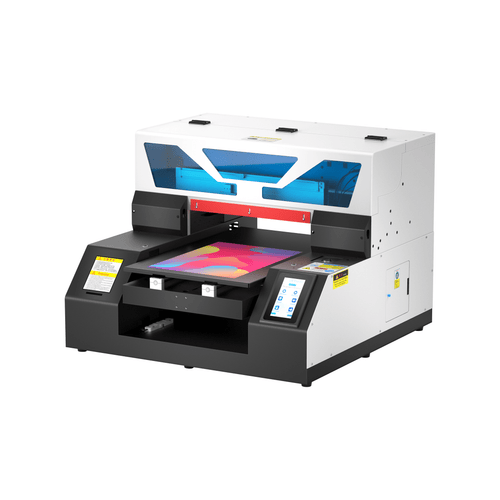

UV DTF Technology

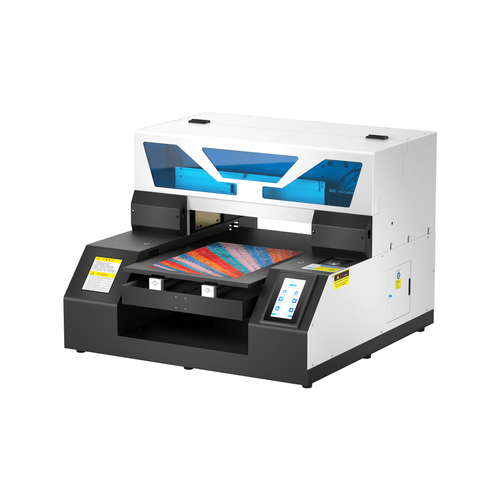

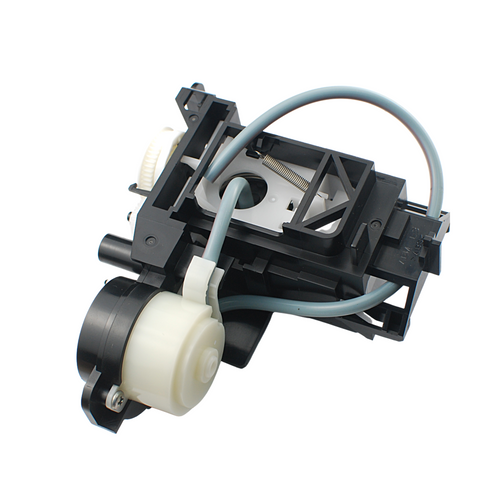

Unlike DTF printing, UV DTF printing normally needs more extra essentials - two films: base film and backing film ; UV light, to cure color inks and varnish ink ; laminator, to laminate two films together.

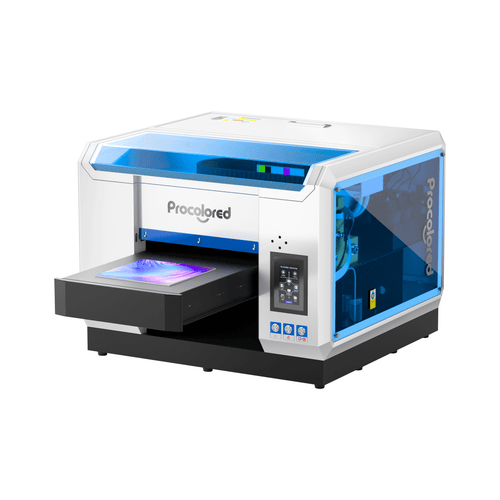

UV DTF printing is commonly used in sticker making industry. It produces crystal stickers that can be applied on most flat or curved substrates. The final finished stickers tend to be durable and widely used in customized decoration, promotional products, signage, labeling and many other creative fields.

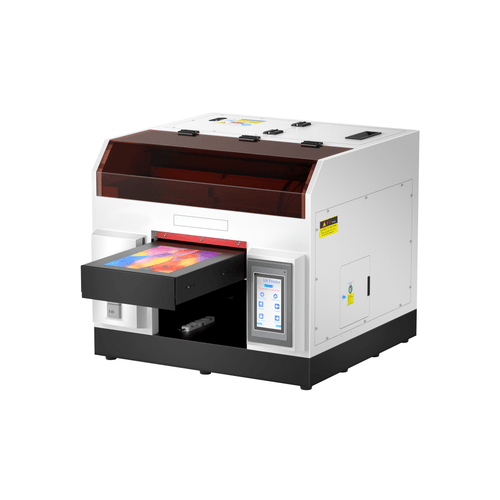

Application

Applicable surface: UV DTF stickers can be applied on different types of rigid surfaces, including electronic devices, vehicle parts, wooden products, metal items, glass or cardboard surfaces and so on. However, they are not suitable for any type of fabric. These stickers are durable and chemical resistant but also removable if you regret the appliance - just use a knife to scratch it off.

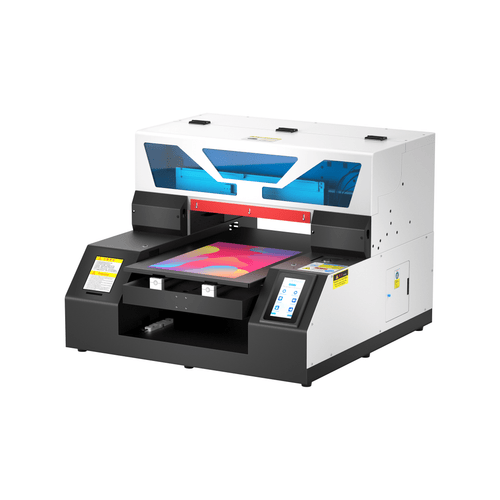

UV DTF Printng Procedures:

- UV DTF printer first prints on base film using UV-curable inks and varnish inks.

- The inks will be cured via UV lights built in the printer.

- Use a laminator to laminate the base film and backing film together.

- Get the printing part you need, peel off the base film and patch the printing onto substrates.

- Give the printing some pressing and then peel off the backing film.