Nowadays more and more people want to do customized things to show personality and novelty, the industry of custom t-shirt printing has expanded rapidly over the last few years in many countries, and direct to film printer is a relatively new player in the textile printing industry. DTF, or Direct to Film, is a printing method that uses white ink as a base to produce high-quality, vibrant designs on various fabrics (different from uv dtf printer). Like other printing methods, DTF also has its pros and cons. When it comes to selecting the best dtf printer for small business, reliability and efficiency are the most considered factors. However, many people still have great doubts about DTF printing technology and do not understand its advantages and disadvantages. In this article, we will briefly discuss its pros and cons.

Pros:

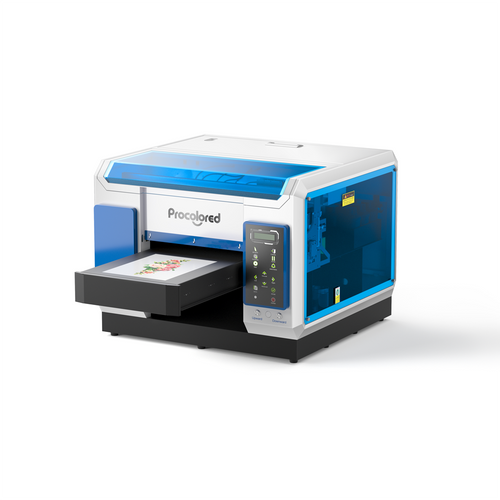

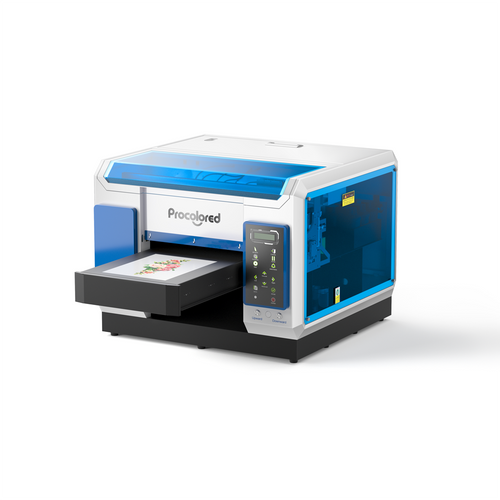

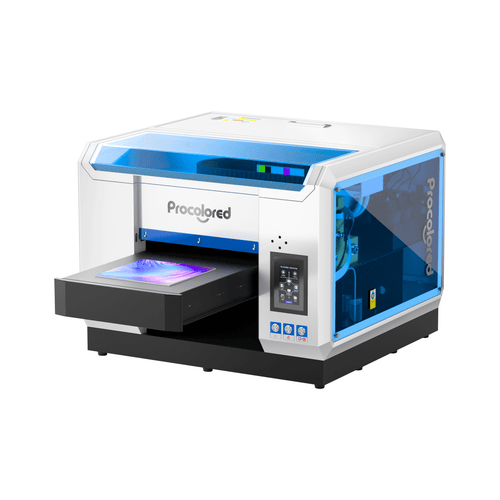

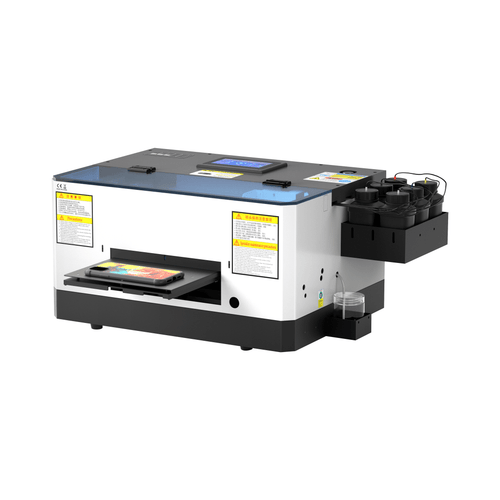

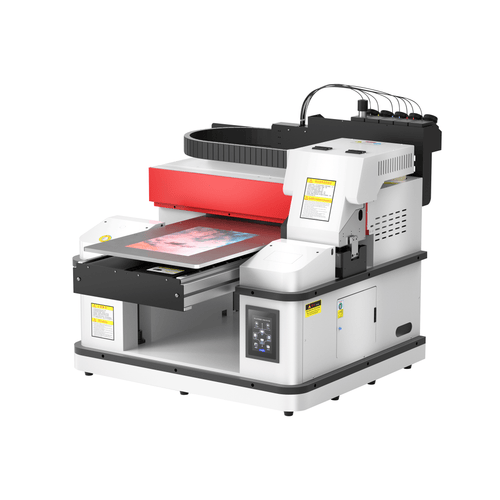

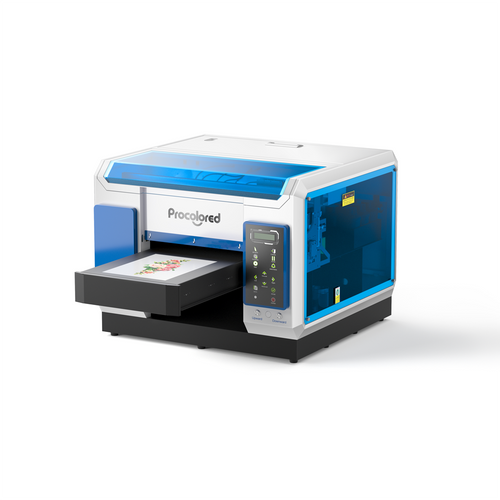

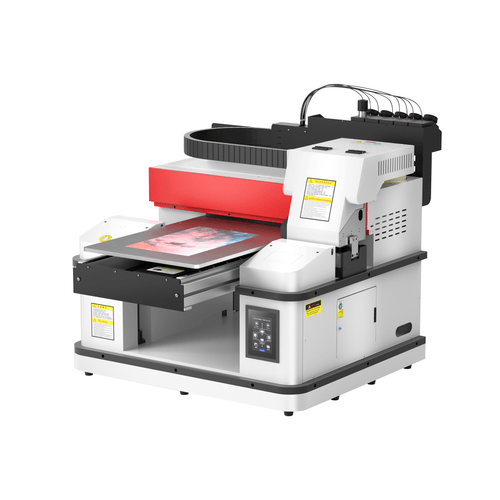

Simple operation, easy to master: One of the most significant advantages of DTF printing is its simple operation. Compared to other tshirt printing machines, such as DTG printer, DTF printer is quite easy to master. This means that beginners can quickly learn how to use the equipment and produce high-quality prints without extensive training, you just need to print your image with a RIP software and PET films, then transfer it to any fabrics you want, it doesn't have any restrictions.

No limitation to fabrics: Another significant advantage of DTF Tshirt printer is its wide applicability to different fabrics. This method can print on almost any fabric, including cotton, polyester, and even leather. Additionally, DTF printing is not limited by fabric color, as it uses white ink as a base, which allows for printing on dark fabrics.

Vibrant colors: The best DTF printer are expected to produce vivid colors and strong layering. The white ink base allows for vibrant color reproduction and ensures that designs are crisp and clear. This makes it ideal for printing complex designs with intricate details and multiple colors.

Stable and durable: DTF prints are highly stable and durable. The white ink is used as a layer of background color, and the colored ink is on it, and then pasted on the fabric through an adhesive material, which makes it less likely to peel or fade after multiple washes. This is a critical factor to consider when designing custom t-shirts that need to withstand frequent use and washing. Learn more about how to make dtf transfers at home.

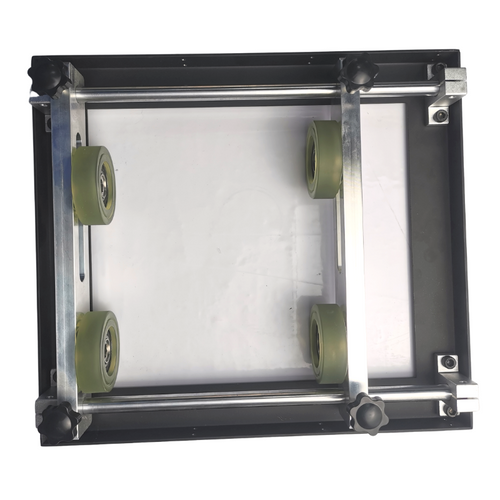

Can combine patterns, significantly improve efficiency when batch printing: DTF printing allows for combining patterns, which can significantly improve efficiency when batch printing. This means that multiple designs can be printed at once, which saves time and effort. This is an essential advantage for businesses that need to produce large quantities of t-shirts.

Cons:

Color deviation: One of the main disadvantages of DTF printing is the potential for color deviation. The white ink base can affect the final color of the print, which can be challenging to predict. If the printhead gets clogged on some nozzles it will also cause color deviation. This can result in color variations between prints, which may not be acceptable for some customers.

White ink issues: DTF printing uses white ink as a base, which can cause issues such as clogging of the nozzle and difficulty in printing. Due to the characteristics of white ink itself, it is prone to sedimentation, resulting in poor printing effect of white and may clog the nozzle, Procolored DTF machine has a white ink stirring and cycling system to prevent the issue.

Breathability and feel: Another disadvantage of DTF printing is that it can affect the breathability and feel of the t-shirt. The ink can make the fabric feel stiffer, which may be uncomfortable for some customers. This can be a critical factor to consider when designing t-shirts for everyday wear.

Nozzle clogging problems: The print head used by the DTF printer is the same as other inkjet printers, which needs to be used and maintained frequently. If it is not used for a long time, the ink inside the print head will dry up, which will cause the nozzle to be clogged. If it is not used for more than three days, we recommend using the print head protection device to inject moisturizing liquid into the print head to protect the print head

Cracks may appear after multiple washes: Although DTF printing is generally durable, cracks may appear on the print after multiple washes. This can be a concern for customers who expect their custom t-shirts to last for a long time. So choosing a high-quality adhesive is a good choice to improve this situation

DTF printing has both advantages and disadvantages for t-shirt design. Its versatility, ease of operation, and ability to produce high-quality prints make it a valuable tool for businesses that need to produce custom t-shirts. However, color deviation, white ink issues, and nozzle clogging problems may be a concern for some customers. But after mastering how to use it, you will find that it has obvious advantages in terms of efficiency and quality compared to other printing methods.

Other sources:

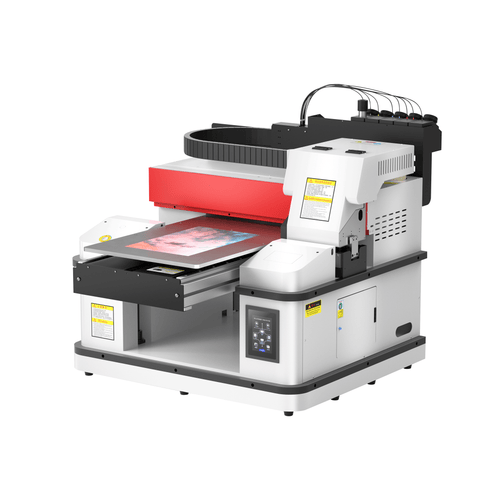

Explore DTG printer for sale to start your T-shirt small business.

Explore Differences of DTF transfers and UV DTF transfers