The Ingredients of White Ink

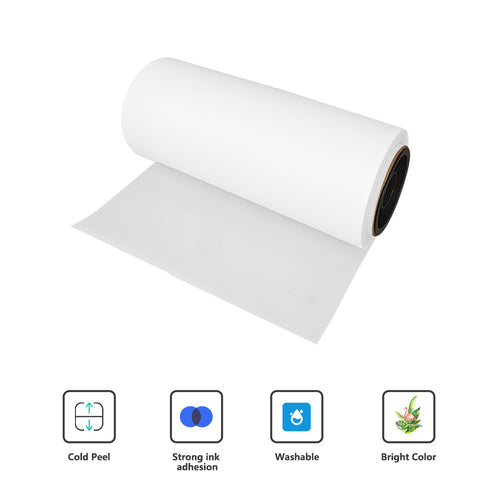

Titanium dioxide is widely used as a white pigment in various industries. The main components of white ink are titanium powder and solvent. Titanium white pigment are dispersed throughout a suspension. Although the suspension is viscous enough, the powder particles are likely to settle to the bottom if the white ink is left undisturbed for a long time.Those tiny particles can cause clogging issues in the ink system and affect printing results. After a long-term use, the print head will gradually become clogged. The lifespan of the print head is generally about 8-12 months.

Characteristics of White Ink

The white ink contains oily solvent, if the print head is left exposed to the air for a long time, when the room temperature is elevated, the solvent will slowly evaporate, and the particles in the ink will clog the nozzle. Therefore, when the printer is not in use, make sure the print head are tightly sealed in the capping station. And DTF inks will chemically react with alcohol, causing the solvent to evaporate quickly, so it is prohibited to use alcohol to wipe the bottom of the print head, otherwise it will cause the nozzle to become clogged.

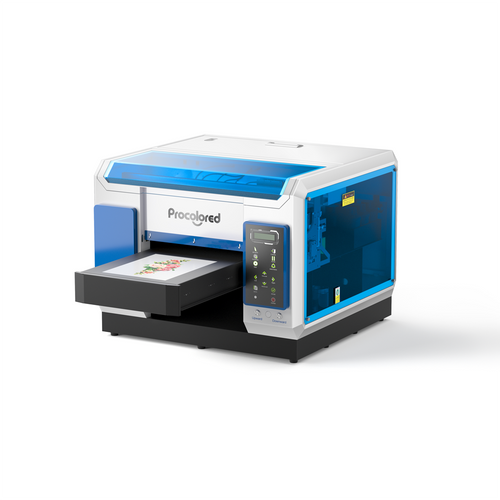

The ink needs to be stored away from light, and the machine should also be kept away from direct sunlight. It is recommended to use Procolored DTF ink. Be sure not to use inferior DTF ink. Procolored inks have been tested for a long time and are highly compatible with printers and RIP software. The smoothness of printing, the ability to avoid clogging, and the vibrant colors have been recognized by a large number of users. If you cannot purchase Procolored brand DTF ink and want to purchase other brands of ink for mixing, please contact Procolored’s technical staff, we will confirm and walk you through.

Usage Recommendations:

Ink has a shelf life. The shelf life of unopened ink is six months, and the shelf life of opened ink is three months. But the ink should be more than 1/3 of the ink tank to ensure normal ink supply. Before adding new ink to the machine, it is best to shake the ink bottle to reduce sedimentation.

If the printer is not used for more than half an hour, due to the characteristics of white ink and gravity, it is necessary to perform print-head self-cleaning on the software before printing images to avoid ink deviation.

It is recommended that you use this printer as much as possible. Use this printer more frequently to maintain a perfect effect. It is recommended that you operate nozzle check every day, pay attention to the status of the print head, and deal with small problems or defects in time to avoid serious blockage.

If you need to go on a vacation or if you will not use the printer for more than three days, use a moisturizing device to protect the print head. Avoid ink solidifying in the internal channels of the print head and causing the print head to become clogged.

When white ink is brand new, the printing outcome is the best. As time goes by, the concentration of white ink will decrease. Please shake the ink tank regularly to reduce sedimentation and increase its activity.

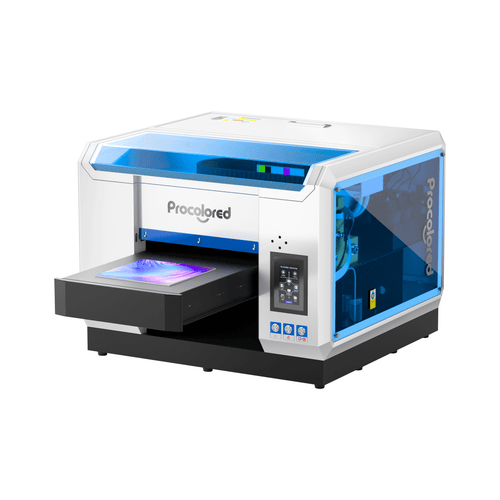

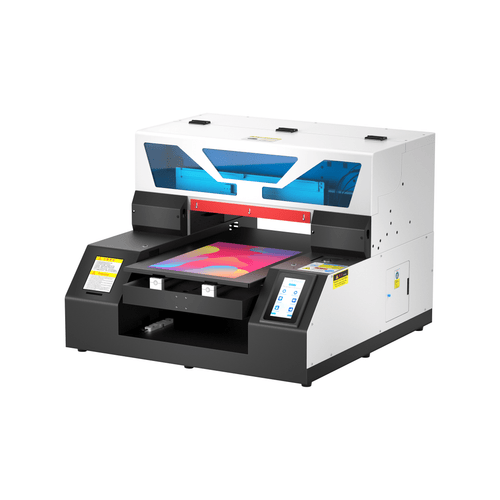

Advantages of Procolored Printers

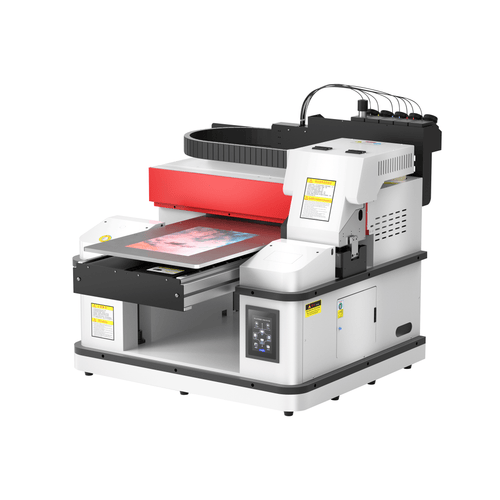

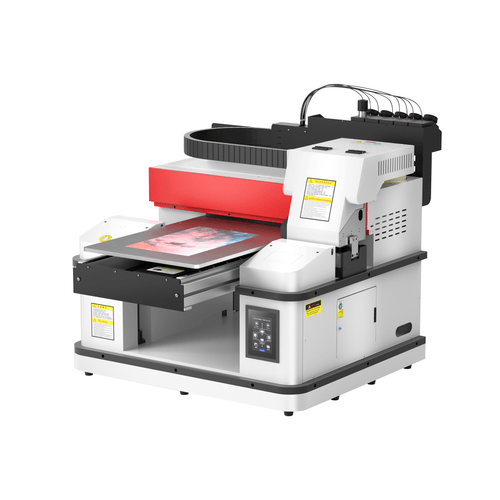

White ink system configuration: The new DTF-2023 model already has a system which combines white ink circulation, white ink stirring, white ink filtration and other auxiliary functions to minimize white ink sedimentation.

White ink circulation: White ink circulation is an ink circuit system with a loop of a digital direct-injection T-shirt printing machine. The ink can circulate continuously in the ink circuit system. Its function is to prevent white ink from forming sedimentation in the ink circuit system.

White ink stirring: There is a motor in the white ink tank running the stirring stick to stir the ink regularly and prevent it from settling.

White ink filtration: By cooperating with the white circulation, after the white ink passes through the circulation, the filter can filter out the large particles of sediment to prevent clogging of the print head.

Case 2: White Ink Gradually Fades After a Period

Possible reasons:

a. Printer nozzle gets slightly clogged.

b. White ink sediments in the ink tank.

c. Filters in the ink dampers is stuffed up.

d. Low printing ratio of white inks.

e. White ink is out of its shelf life and has a low concentration.

Troubleshoot steps:

1. After printing your image, immediately print a test page to check whether it's in a good status.

2. Replace the white ink dampers, the damper has a filter inside. It should be replaced every six months.

3. Shake the white ink tank vigorously to increase the activity of the white ink and reduce sediment. Then extract the ink from the damper and clean the print head in the software.

4. Increase the ratio of white inks in the printing software.

5. If the above steps still cannot fix the issue, and the printhead is in good condition, please empty the white ink tank and add new ones to solve this problem

Case 1: The Test Page Has Broken Lines.

Possible reasons:

a.Ink lacking

b.Inks drying up at the nozzles.

Troubleshoot steps:

1. Print the test page to check the nozzle status

2. Check whether the white ink is sufficient, it should not be less than one-third of the ink tank.

3. Use a syringe to extract 5ml ink from each ink damper to get the inks run smoothly.

4. Restart the machine, extract 5ml ink from the waste ink tube when the power button is solid green.

5. Execute print-head self-cleaning in the software.

6. Print the test page again to check the nozzle status.

7. If there are still many broken lines, please contact Procolored tech staff for further solutions.

Case 4: White Lines in Mixed Color on The Test Page

Possible reasons:

a.Broken ink circuits in the nozzles. (Not common)

b.Clogging issue of suction motor in the capping station. Waste inks on the capping station flow back into the nozzles.

Troubleshoot steps:

1. Print the test page to check the nozzle status

2. Clean the capping station and the print-head bottom manually

3. Execute print-head self-cleaning in the software.

4. Print more images to get the mixed ink discharged.

Case 3: The Test Page Has Almost No White Lines

Possible reason: Nozzle clogging

Troubleshoot steps:

1. Print the test page to check the nozzle status

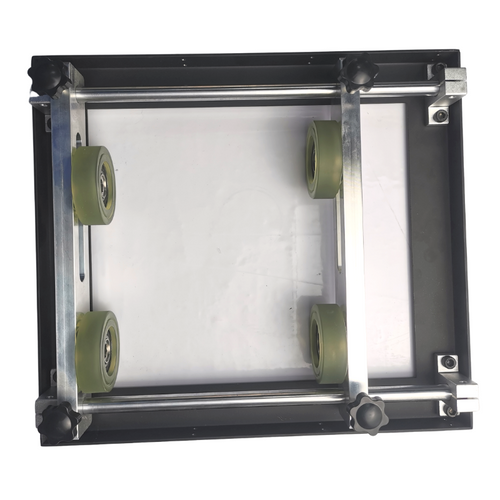

2. Swap the positions of the red and blue ink dampers with 2 white ink dampers.

3. Clean the print head twice in the software

4. Print a new test page to compare

5. If the white lines on the test page are still barely visible, replace the printhead to resolve the issue.