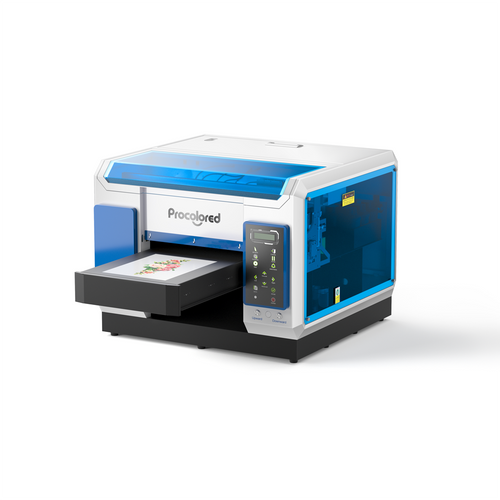

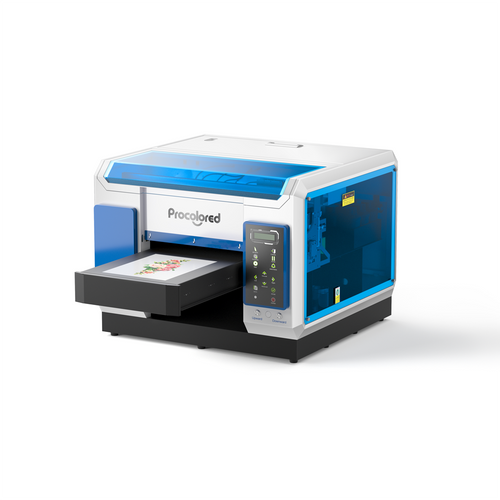

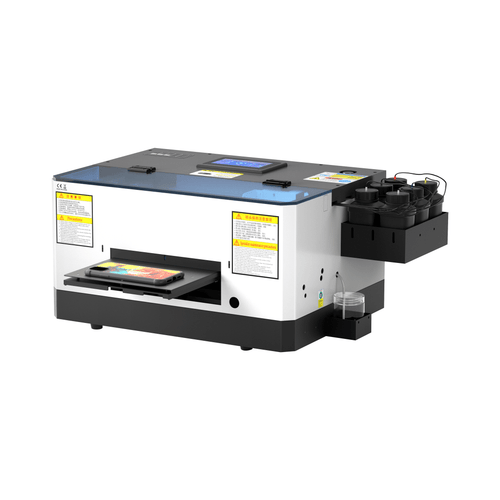

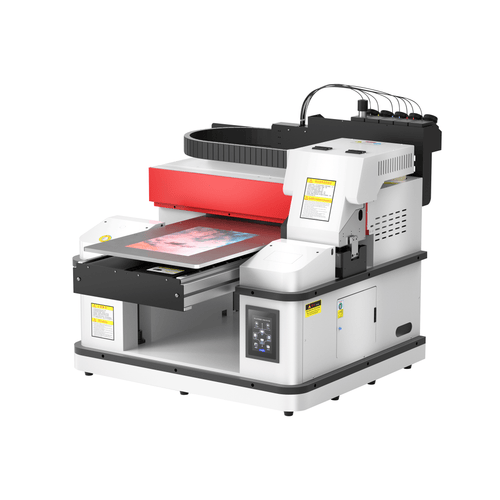

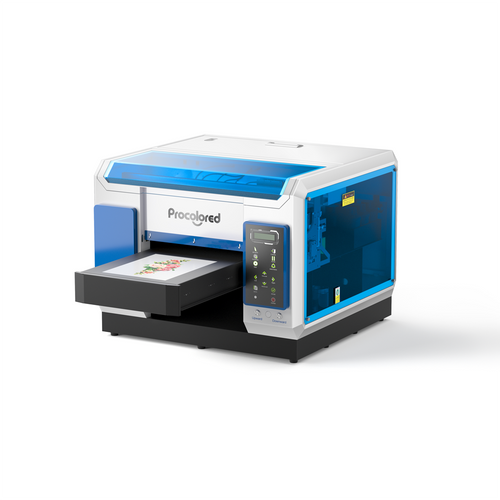

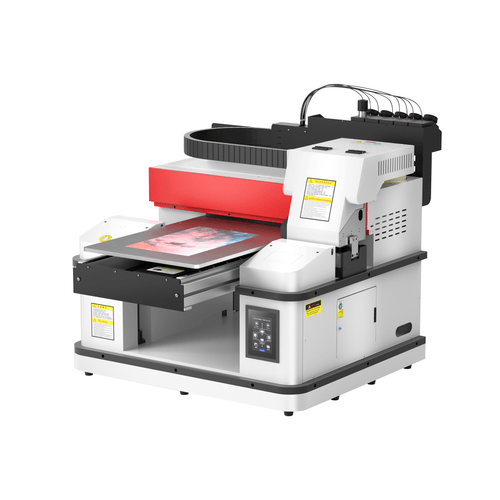

UV DTF Mini Printer

UV DTF sticker printing is a creative printing technique that has gained popularity in the print-on-demand printing industry recent years. People start a small business online or at local stores to selling high-quality, durable, and vibrant stickers and decals.

What is UV DTF decal?

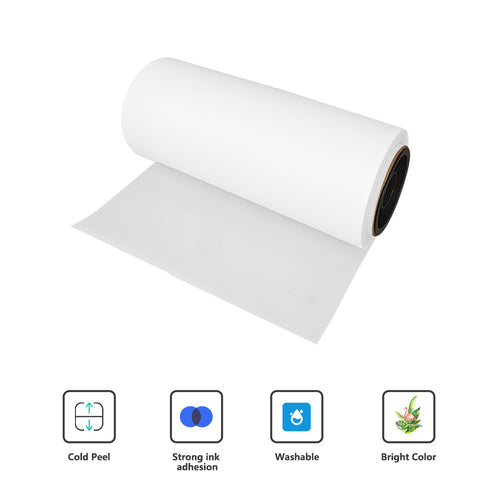

UV DTF decal is a type of weather-resistant sticker that created by UV DTF printer. After a digital printing process, a custom designed image is printed onto a base film sheet (usually called ‘Type-A film’). The base sheet carries adhesive and as the UV-cured inks build up on the base sheet, the adhesive blend with the UV-cured print. There is a release layer on the surface of the base sheet that prevents the adhesive from sticking permanently to the base, so when the UV-cured print is remove from the base to the backing film sheet, the adhesive goes with the print.

A transparent film sheet (usually called ‘Type-B’ film) is used as a backing film sheet to better remove the print off the base film. When the print is peel off from the base film, it is backed up by the type-B backing film. The backing film holds the UV-cured print before the print is transfer onto various surfaces. This UV-cured prints can be used as a durable stickers. They can be used for decoration on vehicles, windows, laptops, cups or phone cases.

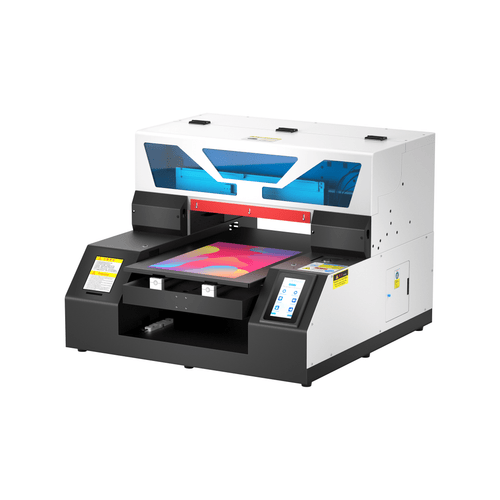

Introducing UV DTF printer

DTF stands for ‘Direct to Film’. The printer prints patterns onto a base film sheet and the inks are cured instantly by ultraviolet light. After the print is transfer together with adhesive onto a backing film, it became a decorative sticker that can apply on various surface. The UV DTF printer offers vibrant colors, durability to the UV DTF decals.

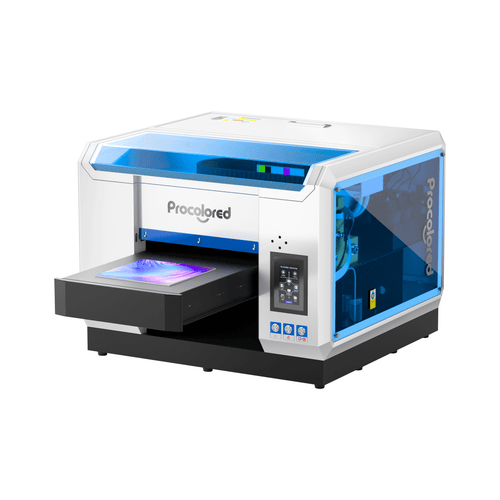

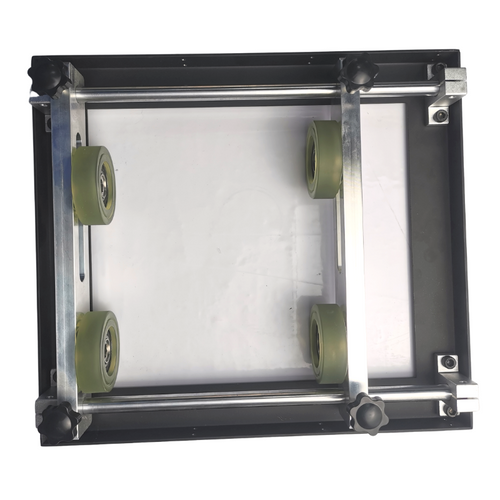

The UV DTF mini printer features dual printhead and a film cutter to improve production efficiency. It is combined with a built-in laminating machine. In the traditional printing process, the pattern printing and film laminating are performed separately by 2 machines. The UV DTF mini printer combines these 2 processes into one. As the printing on the base film going, a film applicator simultaneously covers and laminates the backing film onto the base film to complete the process of sticker printing.

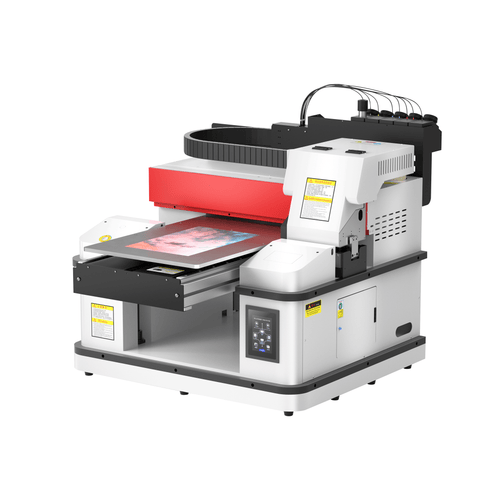

Optimized Structure

The UV DTF mini is optimized in its structure. The size of the printer is much smaller than a normal UV DTF printer, that’s why it called a ‘mini’. And an optional printer cart with casters is added to the printer, making it easy to move around as needed. This also free up some table space for other equipment. However, due to its multi functions, it is more complicated to get everything set up compared with DTF printer. It needs at least 2 persons to finish the printer assembly and film loading. Please follow our installation guidance to finish the job.