Guidance to Choose a Suitable Printer

With Black Friday ongoing, new comers may be confused and hesitated in choosing a suitable printer. Hence here we provide some related guidance. Below chart is only to help you get a brief understanding of which printer your need, don't forget to take time to read the following printer details. If you still got any confusion or questions, feel free to contact our customer services.

Brief Classification of Procolored Printers

Brief Classification of

Procolored Printers

Printer Details & Differences

- dtf

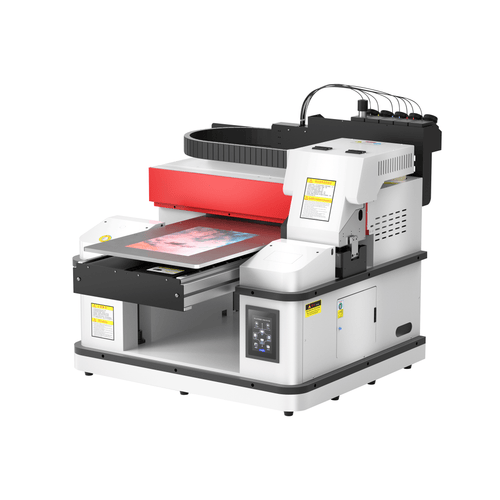

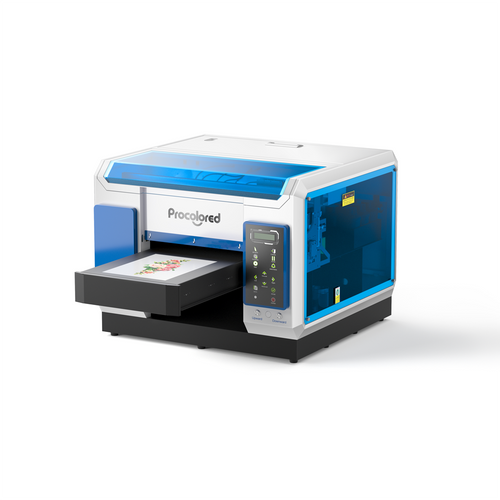

- dtg

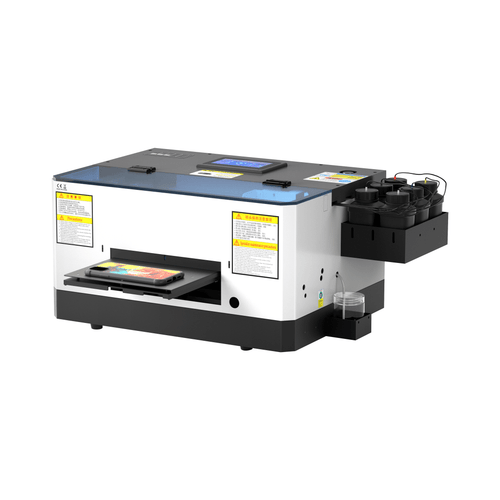

- uv dtf

- uv

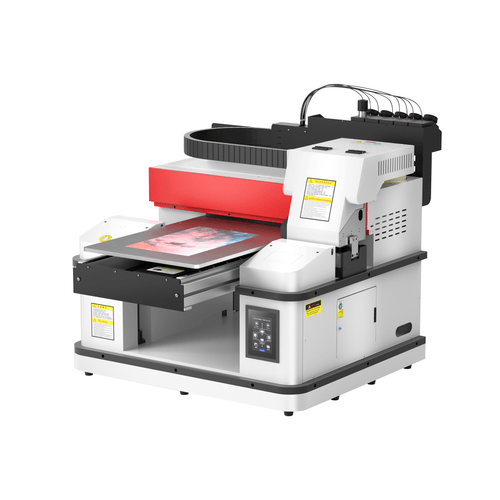

- Key Differences

highly recommended for printing on fabric

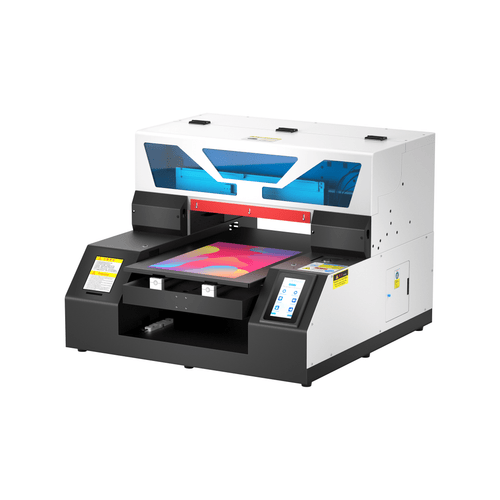

DTF Printer - Direct to Film Printer

The DTF (Direct-to-Film) printing process is suitable for a variety of materials, including textiles and non-textile substrates. The key factor is ensuring that the material can withstand the heat and pressure involved in the DTF transfer process.

Suitably Applied to: Cotton, Polyester, Cotton-polyester blends, Spandex, Nylon, Denim, Canvas

Necessary consumables: DTF ink, DTF film, adhesive powder

DTF ink is formulated to adhere to transfer films and facilitate the transfer of digital designs from the film onto various materials. Typically, there are five colors, CMYKW. It is common to print the image in reverse on the film. First, the colored layer is printed, and then a layer of white is printed to make the colors more vibrant. Therefore, the consumption rate of white ink is faster than that of other colors.

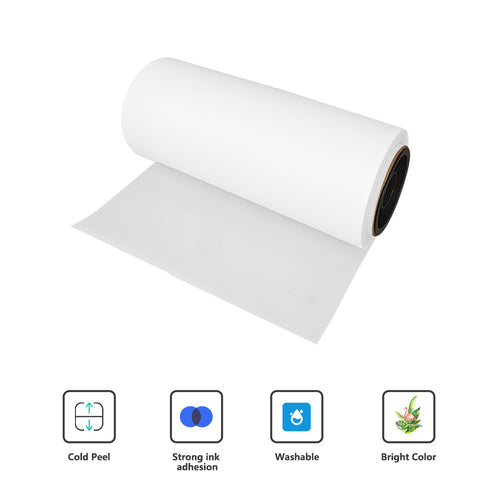

DTF film, also known as DTF transfer film, plays a crucial role in the DTF printing process. DTF film is a specialized type of transparent or semi-transparent film that serves as the medium for transferring digital designs or images onto various materials, primarily textiles and fabrics.

Adhesive powder, in DTF (Direct-to-Film) printing, is a crucial component used to enhance the adhesion of printed designs from the DTF transfer film onto the textiles material.

Necessary equipment: DTF printer, curing oven/ powder shaker, heat press machine

The DTF printer sprays color inks on a specially coated transfer film according to the graphic shape, and then the image print is covered with a layer of white ink.

Curing oven/powder shaker is used to melt the adhesive powder and make it more easy to paste onto the fabric. The next step is to transfer the image to the fabric through a heat press.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

How to use DTF printer: printing - powder application - baking - heat press - peeling - second heat press

Procolored DTF products comparison

more breathable printing

but better used on cotton fabric only

DTG Printer - Direct to Garment Printer

Procolored DTG printer also called direct to garment printer, It enables individuals to customize textiles freely, such as clothing and pillows, which can be applied in many fields. Explore DTG printer for sale to start your T-shirt small business.

The more the cotton content of the fabric contains, the firmer the printing color on fabric lasts and the higher of the washability. The advantage of this new printing technology on fabric is that the fabric is more breathable without feeling of film.

Suitably Applied to: fabric with over 80% cotton would be recommended

Necessary consumables: DTG textile ink, pretreatment liquid

DTG textile ink

Pretreatment liquid should be sprayed on fabric/ garment before printing. This liquid will help ink better get into textiles and achieve intact printing image.

Necessary equipment: DTG printer, heat press machine, garment fixture

The DTG printer sprays color inks on the fabric directly according to the graphic shape, and then the image print is covered with a layer of white ink.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

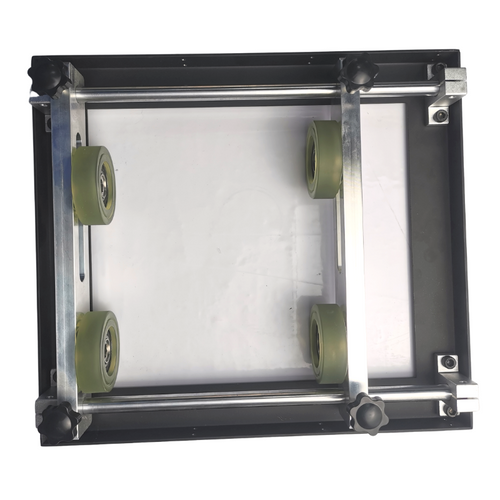

Garment fixture works as a working table for fabric sheet or garment like T-shirts. It helps stabilize the fabric and keep it flat during the printing process.

How to use DTG printer:

design picture - spray pretreatment liquid - hot press fabric - printing - hot press - finish

recommended for sticker making

UV DTF Printer -

Ultraviolet Direct to Film Printer

UV DTF printer is a two-in-one UV DTF printer for printing and laminating. After printing on the A film, it can directly cover the B film on the A film to make crystal stickers. With it, you can play any effect you want, customize cups, customize logos, sell stickers for children, it can achieve what you imagine.

Suitably Applied to:

The finished crystal stickers can be pasted on irregular items, breaking through the limitation of direct printing.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

How to use UV DTF printers:

UV Printer - Ultraviolet Printer

UV printing, also known as ultraviolet printing, is a digital printing technology that uses ultraviolet (UV) light to cure or dry inks and coatings almost instantly as they are printed onto various substrates. This technology is commonly used in commercial printing, packaging, signage, and industrial applications.

Suitably Applied to: hard substrates such as glass, metal sheets, acrylic, and so on

cylindrical objects like cups or mugs (extra fixture needed)

spherical objects or fixed-size cards (extra fixture needed)

If the printed patterns are prone to smudging or peeling, you can apply coatings on the surface of the substrate to enhance the adhesion of the images. Common coatings include acrylic coatings, metal coatings, and so on. After using them, the images adhere more securely and become more durable.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

Key function: automatic height measurement

Procolored's UV printer features automatic height measurement. There are two infrared light emitters on both sides of the printer platform. When the platform raises the substrate to the height of the infrared beams, it automatically stops ascending. The distance from the infrared beams to the print head is the optimal printing distance, typically around 2mm.

Extra equipment (depending on your own needs) : cylindrical objects fixture

This fixture is needed if you intend to print on cylindrical objects. Below video for you information about its actual application, for more details, please feel free to contact our customer services.

Procolored UV products comparison

DTF and DTG printers are both used to print on fabrics. Obviously from their names we can notice their key difference: DTF printer prints on film first and then the printing will be applied to fabric; while DTG printer directly prints on fabric and this allows the fabric keep breathable.

It sounds that DTG printer is much more convenient, but generally we highly recommend users to get a DTF printer for fabric printing but not a DTG one, based on below points:

1.DTF printer has a wider range of suitable substrates:

DTF (Direct-to-Film) printing is a highly versatile printing method that can be used on a variety of substrates such as cotton, polyester, nylon, and more; while DTG printing is typically used on fabrics with over 80% cotton. Though it can also be used on some blends and synthetic materials, the results may not be as good as on pure cotton.

2.DTF printer is a more lightweight printer.

With smaller and lighter printer structure and size, not only small business holders but ordinary people can use DTF printers to achieve personal creation.

3.DTF printers can achieve more striking printings.

DTG printings somehow will be affected by base fabric color, however, DTF first prints on the film and then transfers to fabric itself, highly reserving the actual color saturation.

UV printers and UV DTF printers both fall under the category of UV printing machines. Both of them require UV lamps to dry and fix the ink. Their key differences can be seen below:

1.UV DTF printers have an integrated laminator

UV DTF printer combines the printing and laminating functions, making sticker printing more convenient.

2.Yet UV DTF printers cannot be used for direct printing on objects; they are limited to sticker printing. Instead, UV printers can be used to print on various substrates directly. (UV printers can also achieve sticker making, but you would need to use a laminator to adhere A-film and B-film together).

Printer Details & Differences

- dtf

- dtg

- uv dtf

- uv

- Key Differences

highly recommended for printing on fabric

DTF Printer - Direct to Film Printer

The DTF (Direct-to-Film) printing process is suitable for a variety of materials, including textiles and non-textile substrates. The key factor is ensuring that the material can withstand the heat and pressure involved in the DTF transfer process.

Suitably Applied to:

Cotton, Polyester, Cotton-polyester blends, Spandex, Nylon, Denim, Canvas

Necessary consumables: DTF ink, DTF film, adhesive powder

DTF ink is formulated to adhere to transfer films and facilitate the transfer of digital designs from the film onto various materials. Typically, there are five colors, CMYKW. It is common to print the image in reverse on the film. First, the colored layer is printed, and then a layer of white is printed to make the colors more vibrant. Therefore, the consumption rate of white ink is faster than that of other colors.

DTF film, also known as DTF transfer film, plays a crucial role in the DTF printing process. DTF film is a specialized type of transparent or semi-transparent film that serves as the medium for transferring digital designs or images onto various materials, primarily textiles and fabrics.

Adhesive powder, in DTF (Direct-to-Film) printing, is a crucial component used to enhance the adhesion of printed designs from the DTF transfer film onto the textiles material.

Necessary equipment: DTF printer, curing oven/ powder shaker, heat press machine

The DTF printer sprays color inks on a specially coated transfer film according to the graphic shape, and then the image print is covered with a layer of white ink.

Curing oven/powder shaker is used to melt the adhesive powder and make it more easy to paste onto the fabric. The next step is to transfer the image to the fabric through a heat press.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

How to use DTF printer: printing - powder application - baking - heat press - peeling - second heat press

Procolored DTF products comparison

more breathable printing

but better used on cotton fabric only

DTG Printer - Direct to Garment Printer

Procolored DTG printer also called direct to garment printer, It enables individuals to customize textiles freely, such as clothing and pillows, which can be applied in many fields. Explore DTG printer for sale to start your T-shirt small business.

The more the cotton content of the fabric contains, the firmer the printing color on fabric lasts and the higher of the washability. The advantage of this new printing technology on fabric is that the fabric is more breathable without feeling of film.

Suitably Applied to: fabric with over 80% cotton would be recommended

Necessary consumables: DTG textile ink, pretreatment liquid

DTG textile ink

Pretreatment liquid should be sprayed on fabric/ garment before printing. This liquid will help ink better get into textiles and achieve intact printing image.

Necessary equipment: DTG printer, heat press machine, garment fixture

The DTG printer sprays color inks on the fabric directly according to the graphic shape, and then the image print is covered with a layer of white ink.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

Garment fixture works as a working table for fabric sheet or garment like T-shirts. It helps stabilize the fabric and keep it flat during the printing process.

How to use DTG printer: design picture - spray pretreatment liquid - hot press fabric - printing - hot press - finish

recommended for sticker making

UV DTF Printer -

Ultraviolet Direct to Film Printer

UV DTF printer is a two-in-one UV DTF printer for printing and laminating. After printing on the A film, it can directly cover the B film on the A film to make crystal stickers. With it, you can play any effect you want, customize cups, customize logos, sell stickers for children, it can achieve what you imagine.

Suitably Applied to:

The finished crystal stickers can be pasted on irregular items, breaking through the limitation of direct printing.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

How to use UV DTF printers:

UV Printer - Ultraviolet Printer

UV printing, also known as ultraviolet printing, is a digital printing technology that uses ultraviolet (UV) light to cure or dry inks and coatings almost instantly as they are printed onto various substrates. This technology is commonly used in commercial printing, packaging, signage, and industrial applications.

Suitably Applied to: hard substrates such as glass, metal sheets, acrylic, and so on

cylindrical objects like cups or mugs (extra fixture needed)

spherical objects or fixed-size cards (extra fixture needed)

If the printed patterns are prone to smudging or peeling, you can apply coatings on the surface of the substrate to enhance the adhesion of the images. Common coatings include acrylic coatings, metal coatings, and so on. After using them, the images adhere more securely and become more durable.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

Key function: automatic height measurement

Procolored's UV printer features automatic height measurement. There are two infrared light emitters on both sides of the printer platform. When the platform raises the substrate to the height of the infrared beams, it automatically stops ascending. The distance from the infrared beams to the print head is the optimal printing distance, typically around 2mm.

Extra equipment (depending on your own needs) : cylindrical objects fixture

This fixture is needed if you intend to print on cylindrical objects. Below video for you information about its actual application, for more details, please feel free to contact our customer services.

Procolored UV products comparison

DTF and DTG printers are both used to print on fabrics. Obviously from their names we can notice their key difference: DTF printer prints on film first and then the printing will be applied to fabric; while DTG printer directly prints on fabric and this allows the fabric keep breathable.

It sounds that DTG printer is much more convenient, but generally we highly recommend users to get a DTF printer for fabric printing but not a DTG one, based on below points:

1.DTF printer has a wider range of suitable substrates:

DTF (Direct-to-Film) printing is a highly versatile printing method that can be used on a variety of substrates such as cotton, polyester, nylon, and more; while DTG printing is typically used on fabrics with over 80% cotton. Though it can also be used on some blends and synthetic materials, the results may not be as good as on pure cotton.

2.DTF printer is a more lightweight printer.

With smaller and lighter printer structure and size, not only small business holders but ordinary people can use DTF printers to achieve personal creation.

3.DTF printers can achieve more striking printings.

DTG printings somehow will be affected by base fabric color, however, DTF first prints on the film and then transfers to fabric itself, highly reserving the actual color saturation.

UV printers and UV DTF printers both fall under the category of UV printing machines. Both of them require UV lamps to dry and fix the ink. Their key differences can be seen below:

1.UV DTF printers have an integrated laminator.

UV DTF printer combines the printing and laminating functions, making sticker printing more convenient.

2.Yet UV DTF printers cannot be used for direct printing on objects; they are limited to sticker printing. Instead, UV printers can be used to print on various substrates directly. (UV printers can also achieve sticker making, but you would need to use a laminator to adhere A-film and B-film together).

Printer Details & Differences

- dtf

- DTG

- uv dtf

- uv

- Key Differences

highly recommended for printing on fabric

DTF Printer -

Direct to Film Printer

The DTF (Direct-to-Film) printing process is suitable for a variety of materials, including textiles and non-textile substrates. The key factor is ensuring that the material can withstand the heat and pressure involved in the DTF transfer process.

Suitably Applied to:

Cotton, Polyester, Cotton-polyester blends, Spandex, Nylon, Denim, Canvas

Necessary consumables: DTF ink, DTF film, adhesive powder

DTF ink is formulated to adhere to transfer films and facilitate the transfer of digital designs from the film onto various materials. Typically, there are five colors, CMYKW. It is common to print the image in reverse on the film. First, the colored layer is printed, and then a layer of white is printed to make the colors more vibrant. Therefore, the consumption rate of white ink is faster than that of other colors.

DTF film, also known as DTF transfer film, plays a crucial role in the DTF printing process. DTF film is a specialized type of transparent or semi-transparent film that serves as the medium for transferring digital designs or images onto various materials, primarily textiles and fabrics.

Adhesive powder, in DTF (Direct-to-Film) printing, is a crucial component used to enhance the adhesion of printed designs from the DTF transfer film onto the textiles material.

Necessary equipment: DTF printer, curing oven/ powder shaker, heat press machine

The DTF printer sprays color inks on a specially coated transfer film according to the graphic shape, and then the image print is covered with a layer of white ink.

Curing oven/powder shaker is used to melt the adhesive powder and make it more easy to paste onto the fabric. The next step is to transfer the image to the fabric through a heat press.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

How to use DTF printer: printing - powder application - baking - heat press - peeling - second heat press

Procolored DTF products comparison

more breathable printing

but better used on cotton fabric only

DTG Printer - Direct to Garment Printer

Procolored DTG printer also called direct to garment printer, It enables individuals to customize textiles freely, such as clothing and pillows, which can be applied in many fields. Explore DTG printer for sale to start your T-shirt small business.

The more the cotton content of the fabric contains, the firmer the printing color on fabric lasts and the higher of the washability. The advantage of this new printing technology on fabric is that the fabric is more breathable without feeling of film.

Suitably Applied to: fabric with over 80% cotton would be recommended

Necessary consumables: DTG textile ink, pretreatment liquid

DTG textile ink

Pretreatment liquid should be sprayed on fabric/ garment before printing. This liquid will help ink better get into textiles and achieve intact printing image.

Necessary equipment: DTG printer, heat press machine, garment fixture

The DTG printer sprays color inks on the fabric directly according to the graphic shape, and then the image print is covered with a layer of white ink.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

Garment fixture works as a working table for fabric sheet or garment like T-shirts. It helps stabilize the fabric and keep it flat during the printing process.

How to use DTG printer: design picture - spray pretreatment liquid - hot press fabric - printing - hot press - finish

recommended for sticker making

UV DTF Printer -

Ultraviolet

Direct to Film Printer

UV DTF printer is a two-in-one UV DTF printer for printing and laminating. After printing on the A film, it can directly cover the B film on the A film to make crystal stickers. With it, you can play any effect you want, customize cups, customize logos, sell stickers for children, it can achieve what you imagine.

Suitably Applied to:

The finished crystal stickers can be pasted on irregular items, breaking through the limitation of direct printing.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

How to use UV DTF printers:

UV Printer -

Ultraviolet Printer

UV printing, also known as ultraviolet printing, is a digital printing technology that uses ultraviolet (UV) light to cure or dry inks and coatings almost instantly as they are printed onto various substrates. This technology is commonly used in commercial printing, packaging, signage, and industrial applications.

Suitably Applied to: hard substrates such as glass, metal sheets, acrylic, and so on; cylindrical objects like cups or mugs (extra fixture needed); spherical objects or fixed-size cards (extra fixture needed)

If the printed patterns are prone to smudging or peeling, you can apply coatings on the surface of the substrate to enhance the adhesion of the images. Common coatings include acrylic coatings, metal coatings, and so on. After using them, the images adhere more securely and become more durable.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

Key function: automatic height measurement

Procolored's UV printer features automatic height measurement. There are two infrared light emitters on both sides of the printer platform. When the platform raises the substrate to the height of the infrared beams, it automatically stops ascending. The distance from the infrared beams to the print head is the optimal printing distance, typically around 2mm.

Extra equipment (depending on your own needs) : cylindrical objects fixture

This fixture is needed if you intend to print on cylindrical objects. Below video for you information about its actual application, for more details, please feel free to contact our customer services.

Procolored UV products comparison

DTF and DTG printers are both used to print on fabrics. Obviously from their names we can notice their key difference: DTF printer prints on film first and then the printing will be applied to fabric; while DTG printer directly prints on fabric and this allows the fabric keep breathable.

It sounds that DTG printer is much more convenient, but generally we highly recommend users to get a DTF printer for fabric printing but not a DTG one, based on below points:

1.DTF printer has a wider range of suitable substrates:

DTF (Direct-to-Film) printing is a highly versatile printing method that can be used on a variety of substrates such as cotton, polyester, nylon, and more; while DTG printing is typically used on fabrics with over 80% cotton. Though it can also be used on some blends and synthetic materials, the results may not be as good as on pure cotton.

2.DTF printer is a more lightweight printer.

With smaller and lighter printer structure and size, not only small business holders but ordinary people can use DTF printers to achieve personal creation.

3.DTF printers can achieve more striking printings.

DTG printings somehow will be affected by base fabric color, however, DTF first prints on the film and then transfers to fabric itself, highly reserving the actual color saturation.

UV printers and UV DTF printers both fall under the category of UV printing machines. Both of them require UV lamps to dry and fix the ink. Their key differences can be seen below:

1.UV DTF printers have an integrated laminator.

UV DTF printer combines the printing and laminating functions, making sticker printing more convenient.

2.Yet UV DTF printers cannot be used for direct printing on objects; they are limited to sticker printing. Instead, UV printers can be used to print on various substrates directly. (UV printers can also achieve sticker making, but you would need to use a laminator to adhere A-film and B-film together).

Printer Details & Differences

- dtf

- dtg

- uv dtf

- uv

- Key Differences

highly recommended for printing on fabric

DTF Printer - Direct to Film Printer

The DTF (Direct-to-Film) printing process is suitable for a variety of materials, including textiles and non-textile substrates. The key factor is ensuring that the material can withstand the heat and pressure involved in the DTF transfer process.

Suitably Applied to: Cotton, Polyester, Cotton-polyester blends, Spandex, Nylon, Denim, Canvas

Necessary consumables: DTF ink, DTF film, adhesive powder

DTF ink is formulated to adhere to transfer films and facilitate the transfer of digital designs from the film onto various materials. Typically, there are five colors, CMYKW. It is common to print the image in reverse on the film. First, the colored layer is printed, and then a layer of white is printed to make the colors more vibrant. Therefore, the consumption rate of white ink is faster than that of other colors.

DTF film, also known as DTF transfer film, plays a crucial role in the DTF printing process. DTF film is a specialized type of transparent or semi-transparent film that serves as the medium for transferring digital designs or images onto various materials, primarily textiles and fabrics.

Adhesive powder, in DTF (Direct-to-Film) printing, is a crucial component used to enhance the adhesion of printed designs from the DTF transfer film onto the textiles material.

Necessary equipment: DTF printer, curing oven/ powder shaker, heat press machine

The DTF printer sprays color inks on a specially coated transfer film according to the graphic shape, and then the image print is covered with a layer of white ink.

Curing oven/powder shaker is used to melt the adhesive powder and make it more easy to paste onto the fabric. The next step is to transfer the image to the fabric through a heat press.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

How to use DTF printer: printing - powder application - baking - heat press - peeling - second heat press

Procolored DTF products comparison

more breathable printing

but better used on cotton fabric only

DTG Printer - Direct to Garment Printer

Procolored DTG printer also called direct to garment printer, It enables individuals to customize textiles freely, such as clothing and pillows, which can be applied in many fields. Explore DTG printer for sale to start your T-shirt small business.

The more the cotton content of the fabric contains, the firmer the printing color on fabric lasts and the higher of the washability. The advantage of this new printing technology on fabric is that the fabric is more breathable without feeling of film.

Suitably Applied to: fabric with over 80% cotton would be recommended

Necessary consumables: DTG textile ink, pretreatment liquid

DTG textile ink

Pretreatment liquid should be sprayed on fabric/ garment before printing. This liquid will help ink better get into textiles and achieve intact printing image.

Necessary equipment: DTG printer, heat press machine, garment fixture

The DTG printer sprays color inks on the fabric directly according to the graphic shape, and then the image print is covered with a layer of white ink.

Heat press machine is also a must-have tool, using its pressure and heat to transfer printed images onto fabric.

Garment fixture works as a working table for fabric sheet or garment like T-shirts. It helps stabilize the fabric and keep it flat during the printing process.

How to use DTG printer: design picture - spray pretreatment liquid - hot press fabric - printing - hot press - finish

recommended for sticker making

UV DTF Printer -

Ultraviolet Direct to Film Printer

UV DTF printer is a two-in-one UV DTF printer for printing and laminating. After printing on the A film, it can directly cover the B film on the A film to make crystal stickers. With it, you can play any effect you want, customize cups, customize logos, sell stickers for children, it can achieve what you imagine.

Suitably Applied to:

The finished crystal stickers can be pasted on irregular items, breaking through the limitation of direct printing.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

How to use UV DTF printers:

UV Printer - Ultraviolet Printer

UV printing, also known as ultraviolet printing, is a digital printing technology that uses ultraviolet (UV) light to cure or dry inks and coatings almost instantly as they are printed onto various substrates. This technology is commonly used in commercial printing, packaging, signage, and industrial applications.

Suitably Applied to: hard substrates such as glass, metal sheets, acrylic, and so on

cylindrical objects like cups or mugs (extra fixture needed)

spherical objects or fixed-size cards (extra fixture needed)

If the printed patterns are prone to smudging or peeling, you can apply coatings on the surface of the substrate to enhance the adhesion of the images. Common coatings include acrylic coatings, metal coatings, and so on. After using them, the images adhere more securely and become more durable.

Necessary consumables: UV ink, UV varnish

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging.

UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

Key function: automatic height measurement

Procolored's UV printer features automatic height measurement. There are two infrared light emitters on both sides of the printer platform. When the platform raises the substrate to the height of the infrared beams, it automatically stops ascending. The distance from the infrared beams to the print head is the optimal printing distance, typically around 2mm.

Extra equipment (depending on your own needs) : cylindrical objects fixture

This fixture is needed if you intend to print on cylindrical objects. Below video for you information about its actual application, for more details, please feel free to contact our customer services.

Procolored UV products comparison

DTF and DTG printers are both used to print on fabrics. Obviously from their names we can notice their key difference: DTF printer prints on film first and then the printing will be applied to fabric; while DTG printer directly prints on fabric and this allows the fabric keep breathable.

It sounds that DTG printer is much more convenient, but generally we highly recommend users to get a DTF printer for fabric printing but not a DTG one, based on below points:

1.DTF printer has a wider range of suitable substrates:

DTF (Direct-to-Film) printing is a highly versatile printing method that can be used on a variety of substrates such as cotton, polyester, nylon, and more; while DTG printing is typically used on 100% cotton fabrics. Though it can also be used on some blends and synthetic materials, the results may not be as good as on pure cotton.

2.DTF printer is much a lightweight printer.

With smaller and lighter printer structure and size, not only small business holders but ordinary people can use DTF printers to achieve personal creation.

3.DTF printers can achieve more striking printings.

DTG printings somehow will be affected by base fabric color, however, DTF first prints on the film and then transfers to fabric itself, highly reserving the actual color saturation.

DTF and DTG printers are both used to print on fabrics. Obviously from their names we can notice their key difference: DTF printer prints on film first and then the printing will be applied to fabric; while DTG printer directly prints on fabric and this allows the fabric keep breathable.

It sounds that DTG printer is much more convenient, but generally we highly recommend users to get a DTF printer for fabric printing but not a DTG one, based on below points:

1.DTF printer has a wider range of suitable substrates:

DTF (Direct-to-Film) printing is a highly versatile printing method that can be used on a variety of substrates such as cotton, polyester, nylon, and more; while DTG printing is typically used on fabrics with over 80% cotton. Though it can also be used on some blends and synthetic materials, the results may not be as good as on pure cotton.

2.DTF printer is a more lightweight printer.

With smaller and lighter printer structure and size, not only small business holders but ordinary people can use DTF printers to achieve personal creation.

3.DTF printers can achieve more striking printings.

DTG printings somehow will be affected by base fabric color, however, DTF first prints on the film and then transfers to fabric itself, highly reserving the actual color saturation.

UV printers and UV DTF printers both fall under the category of UV printing machines. Both of them require UV lamps to dry and fix the ink. Their key differences can be seen below:

1.UV DTF printers have an integrated laminator

UV DTF printer combines the printing and laminating functions, making sticker printing more convenient.

2.Yet UV DTF printers cannot be used for direct printing on objects; they are limited to sticker printing. Instead, UV printers can be used to print on various substrates directly. (UV printers can also achieve sticker making, but you would need to use a laminator to adhere A-film and B-film together).

Supplementary Suggestions

Below elements should also be taken into consideration while choosing a suitable printer:

1.Maximum dimension of printing:

Procolored provides different printing dimensions for different products, normally including A1, A3, A4 and A5 (depending on specific products). For more details, please visit our product website. And if you’re still hesitated or confused, do feel free to contact our customer services.

2.Type of printing head:

Procolored provides different types of printing heads, including single-array, dual-array and 3-head array. Please noted that each printing head has its pros and cons and is only suitable for specific products. For more detailed information, do feel free to contact our customer services.

Already got a idea for the printing business?

Join our Black Friday Event and get the discounts!

Supplementary Suggestions

Below elements should also be taken into consideration while choosing a suitable printer:

1.Maximum dimension of printing:

Procolored provides different printing dimensions for different products, normally including A1, A3, A4 and A5 (depending on specific products). For more details, please visit our product website. And if you’re still hesitated or confused, do feel free to contact our customer services.

2.Type of printing head:

Procolored provides different types of printing heads, including single-array, dual-array and 3-head array. Please noted that each printing head has its pros and cons and is only suitable for specific products. For more detailed information, do feel free to contact our customer services.

Already got a idea for the printing business?

Join our Black Friday Event and get the discounts!