Title

❌ Buying A Non-Convertible Printer

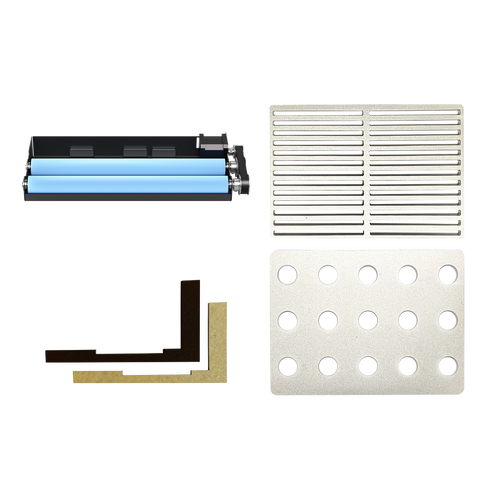

❌ Underestimating Maintenance Needs

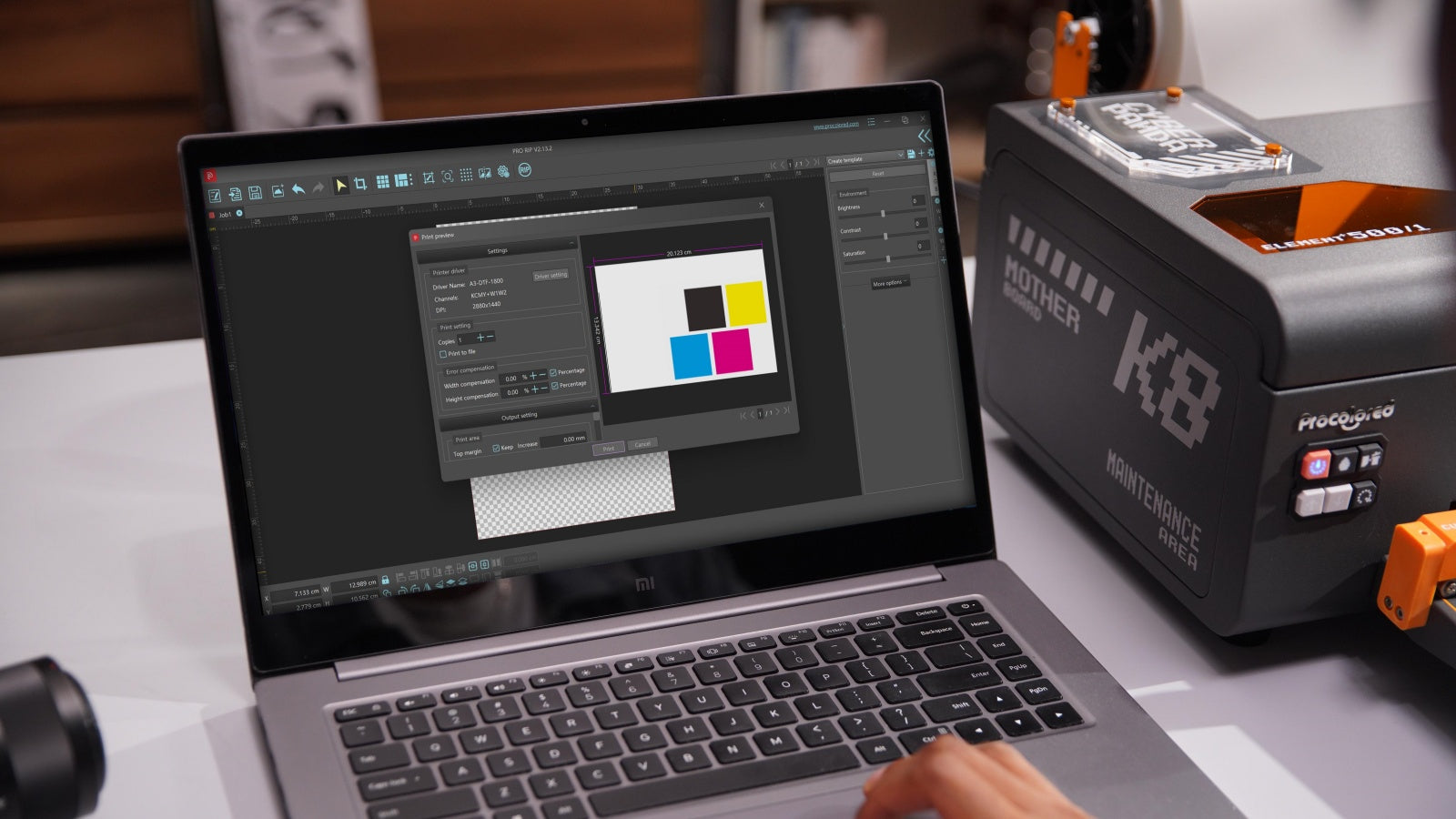

❌ Skimping on Software or Consumables

❌ Overlooking Speed and Scalability Needs

DTF Printer Recommendations Based on Use Case

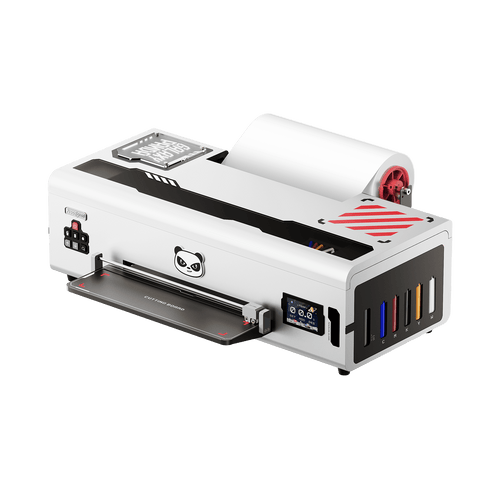

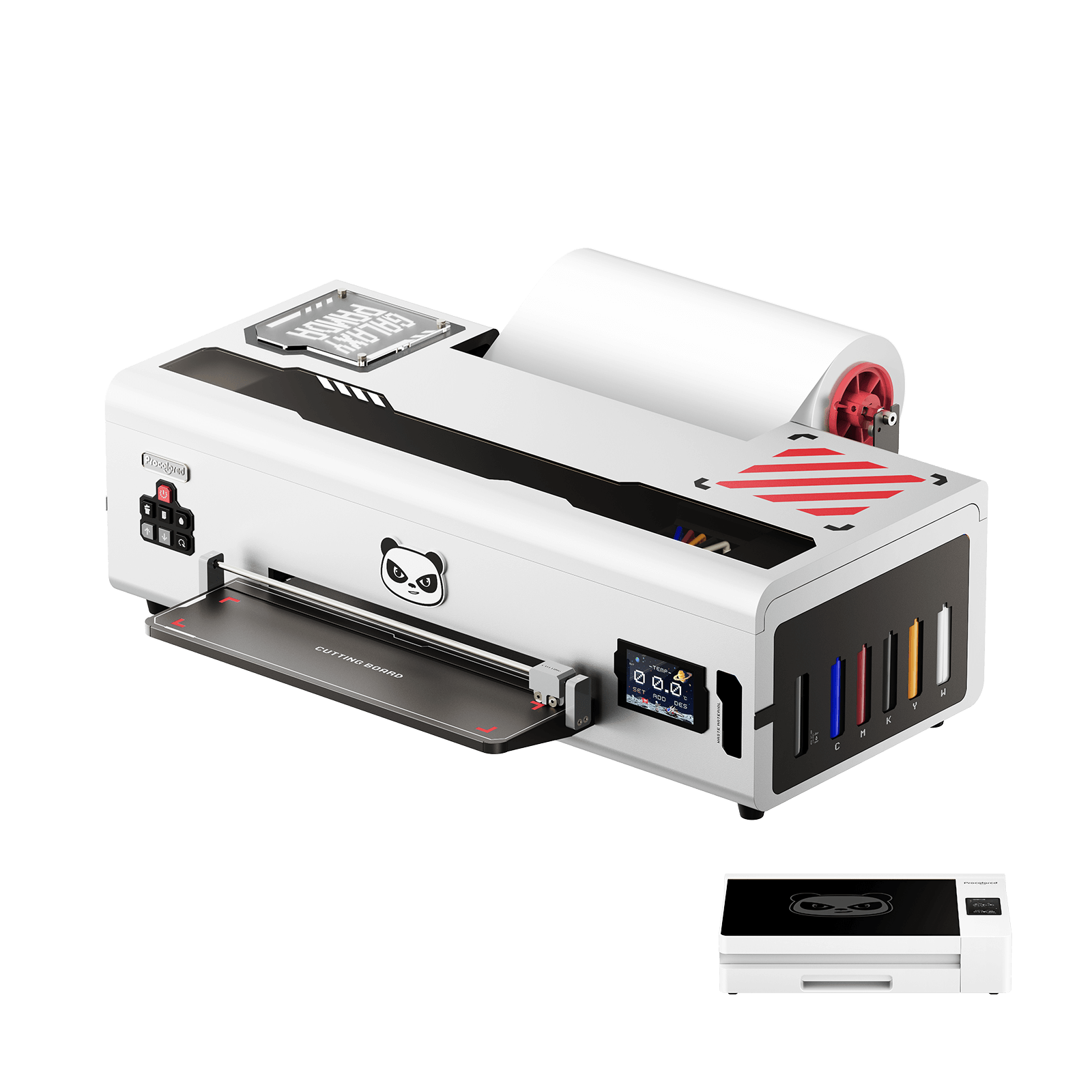

✔️ Expert Hobbyists & Enthusiastic Beginners

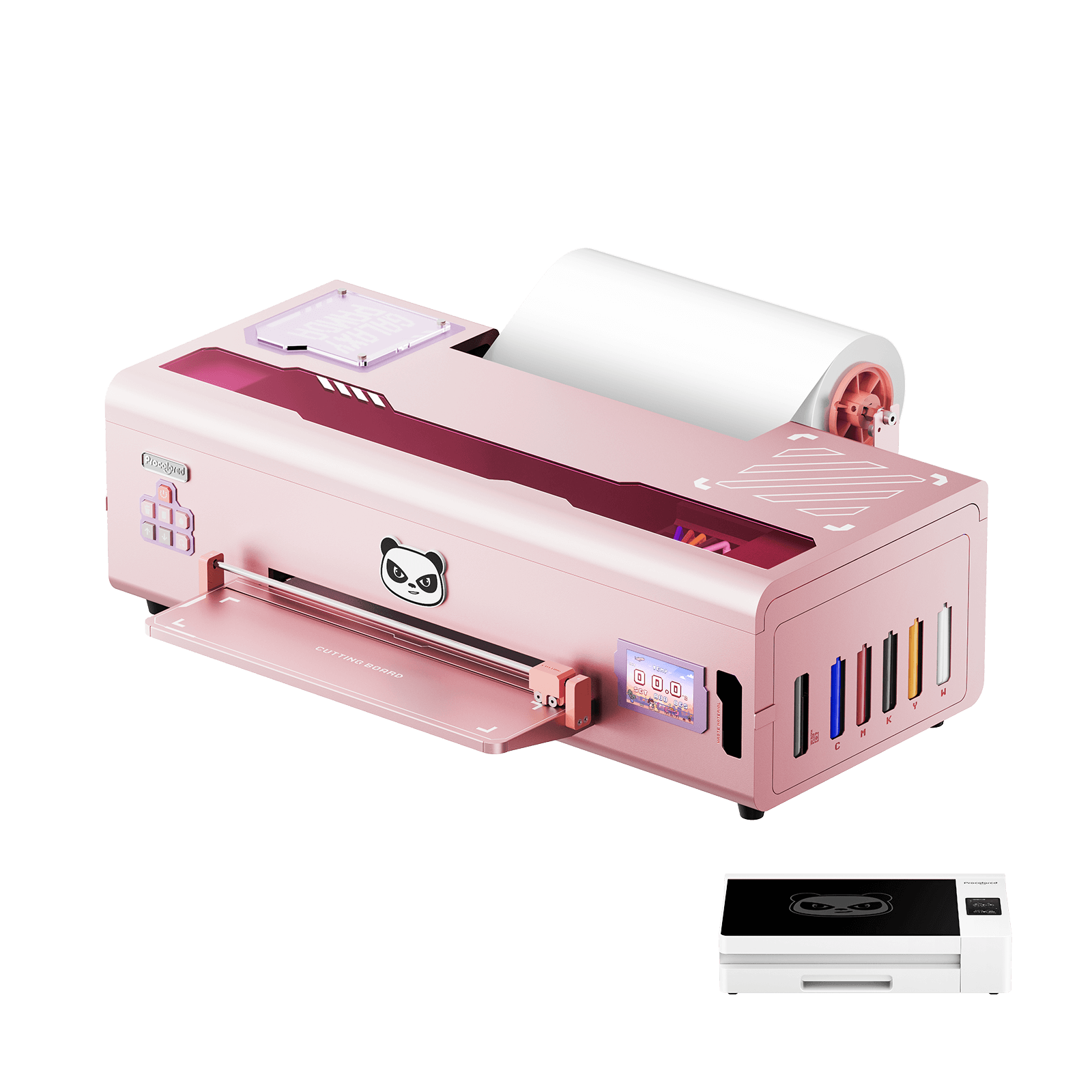

✔️ Busy Creators & Growing Brands

✔️ Print Shops & High Volume Hustlers

Final Verdict: What to Prioritize in a DTF Printer?

Conclusion