In determining whether to use a white toner printer or a DTF setup, your goals, focus product, and the printing frequency are key decision makers. Both have their pros and cons, but the best option always goes after the user’s intent and target audience.

● White Toner Printer

As for white toner printers, their best contestants are small stores, creators, and hobbyists who value versatility. From t-shirts to mugs, even tote bags, wood and acrylic, these printers can handle almost any surface with little to no change in setup.

If you are running an online shop for custom gifts or corporate merchandise, or print on demand items, this option enables you to test and make changes swiftly. It's also perfect for low-to-moderate orders, making it ideal for one-off designs or personalized gifts that don’t need a full production workflow.

● DTF Printing

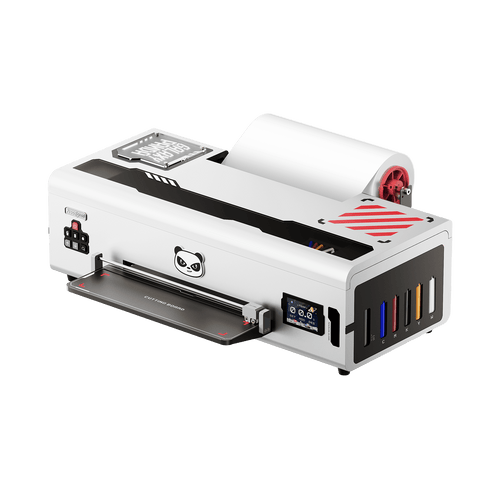

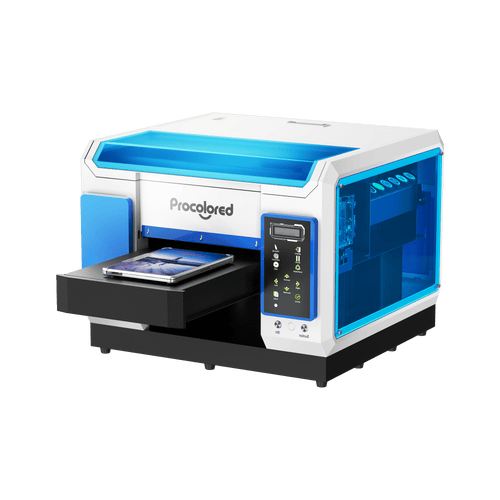

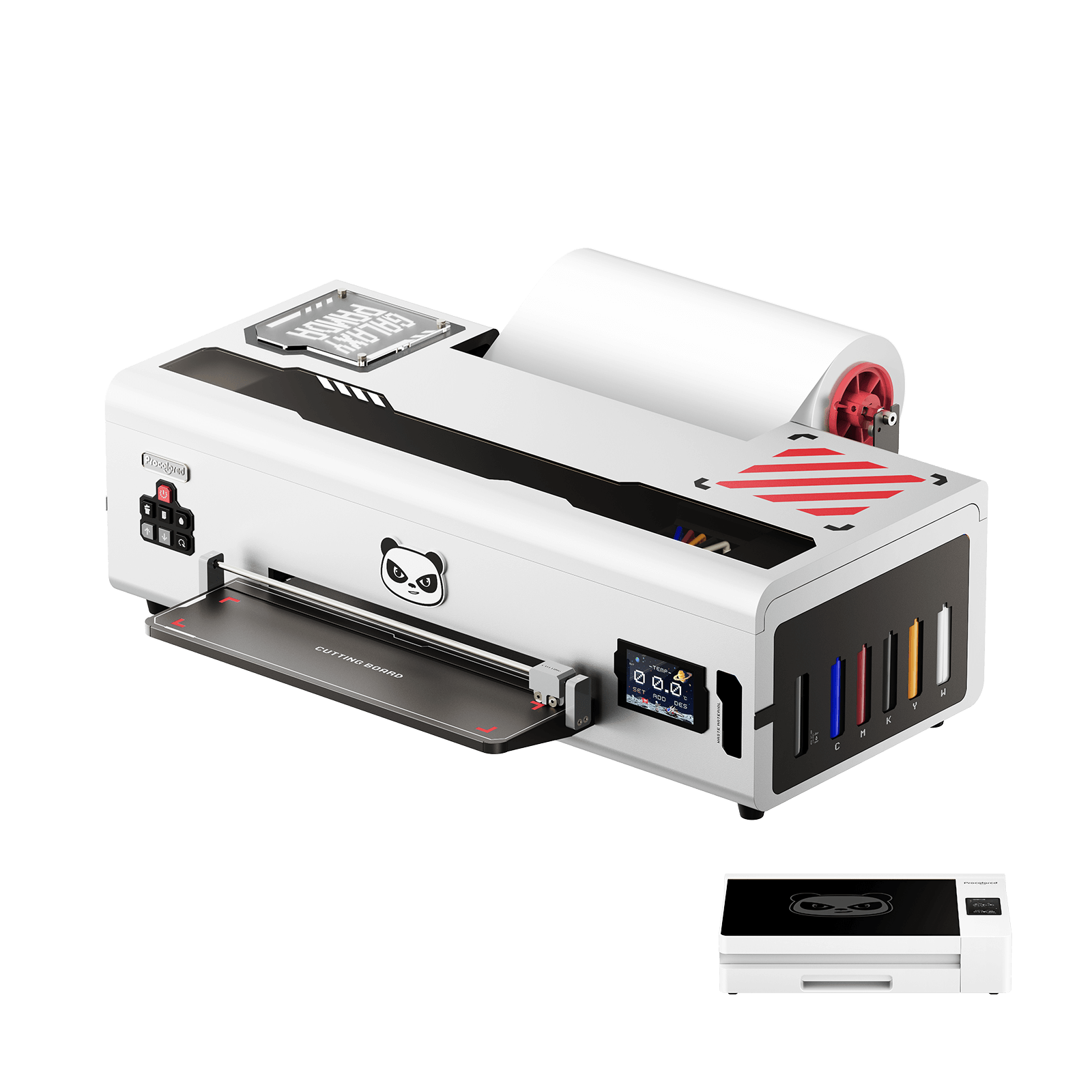

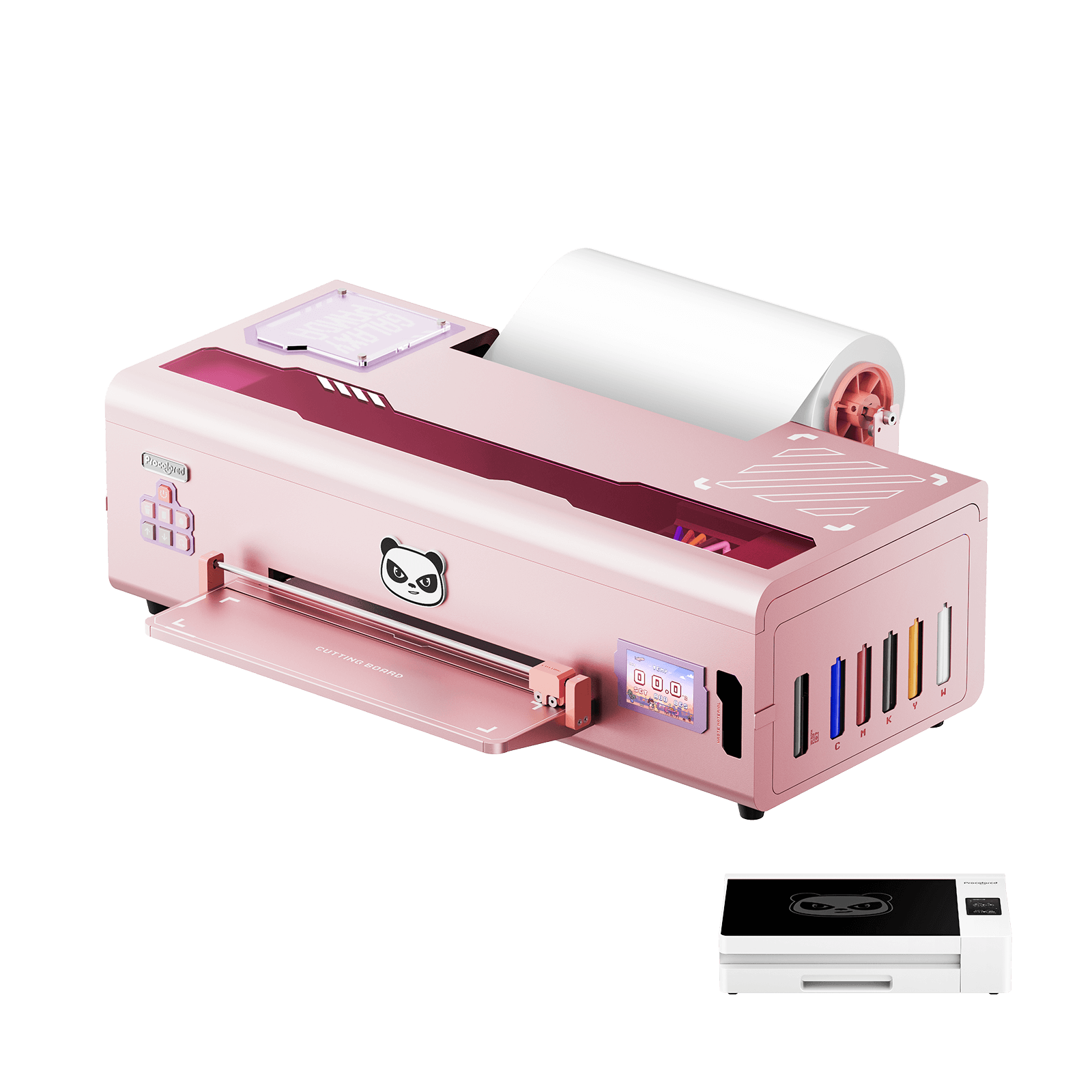

DTF Printing excels in the apparel industry. If you want to launch a clothing brand, operate an Etsy shop, or sell custom bulk sweatshirts, t-shirts, hoodies, and even baby clothes, DTF is your best option.

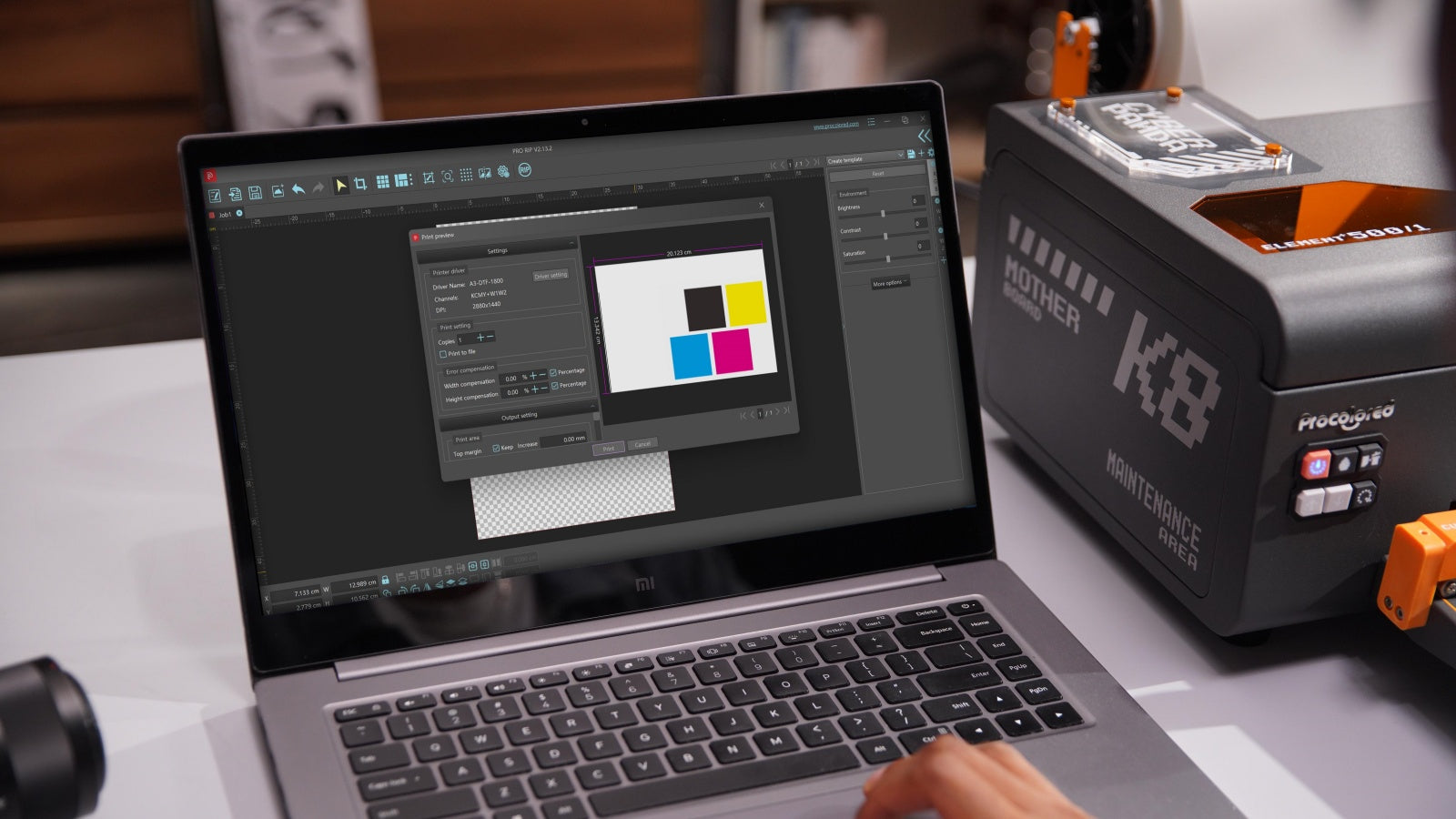

It is meant for stunning prints with durability and large batch jobs with consistency. Thanks to modern machines like Procolored’s DTF Pro, small business owners can achieve professional results without a steep learning curve. Whether you’re selling at craft fairs or fulfilling hundreds of orders online, DTF gives you the quality, durability, and efficiency needed to scale.