Ink can block the print head of an inkjet printer due to a few different reasons:

- Drying: When ink dries on the surface of the print head, it can create a blockage that prevents ink from flowing through the nozzles. This can happen if the printer is not used for an extended period of time, or if the ink cartridges are left exposed to air.

- Impurities: Inkjet printers require clean ink to flow through the print head. If the ink contains impurities or particles, it can clog the nozzles and cause blockages. This can happen if the ink cartridges are not stored properly or if the printer is used with low-quality or expired ink.

- Maintenance: Inkjet printers require regular maintenance to ensure that the print head stays clean and free of blockages. If the printer is not cleaned regularly or if the maintenance cycle is not run when prompted, ink can build up and cause blockages.

- Damage: The print head of an inkjet printer can become damaged over time due to wear and tear or if the printer is mishandled. This can cause blockages or uneven ink flow, which can result in poor print quality or even damage to the printer.

To prevent ink from blocking the print head, it is important to follow the manufacturer's recommendations for ink cartridge storage, run regular maintenance cycles, and handle the printer carefully to avoid damage to the print head.

Here are some tips to effectively prevent the blocking of print heads on inkjet printers:

- Use high-quality ink cartridges: Low-quality ink cartridges may contain impurities or particles that can clog the print head. Using high-quality, manufacturer-recommended ink cartridges can help prevent blockages.

- Keep the printer clean: Regularly clean the printer's exterior and interior, including the print head, to prevent dust, dirt, or other debris from clogging the print head.

- Use the printer regularly: Ink can dry and harden if the printer is not used for an extended period of time. Using the printer regularly can help keep the ink flowing and prevent blockages.

- Run maintenance cycles: Most inkjet printers have a maintenance cycle that can help prevent clogs and other issues. Run the maintenance cycle according to the manufacturer's recommendations to keep the printer running smoothly.

- Store ink cartridges properly: Ink cartridges should be stored in a cool, dry place to prevent drying or evaporation of the ink.

- Handle the printer carefully: Rough handling or improper installation of ink cartridges can damage the print head, leading to blockages or other issues. Follow the manufacturer's instructions for handling and installation.

- Use the printer in a suitable environment: High humidity or extreme temperatures can affect the ink and cause blockages or other issues. Use the printer in a suitable environment with stable temperature and humidity levels.

By following these tips, you can help prevent the blocking of print heads on inkjet printers and ensure that your printer continues to produce high-quality prints.

What is the difference between DTF ink and UV ink, What are the characteristics of DTF ink?

UV ink and DTF ink are two different types of ink used for printing, and they have different characteristics and applications.

UV ink is a type of ink that is cured by ultraviolet (UV) light. When exposed to UV light, the ink undergoes a photochemical reaction that causes it to harden and become dry. It is suitable for printing on a wide variety of surfaces, including plastics, metals, glass, and more.

The UV ink is very durable and resistant to scratches and fading.

UV ink is typically more expensive than other types of ink, and UV printers require a UV light source to cure the ink, which adds to the cost.

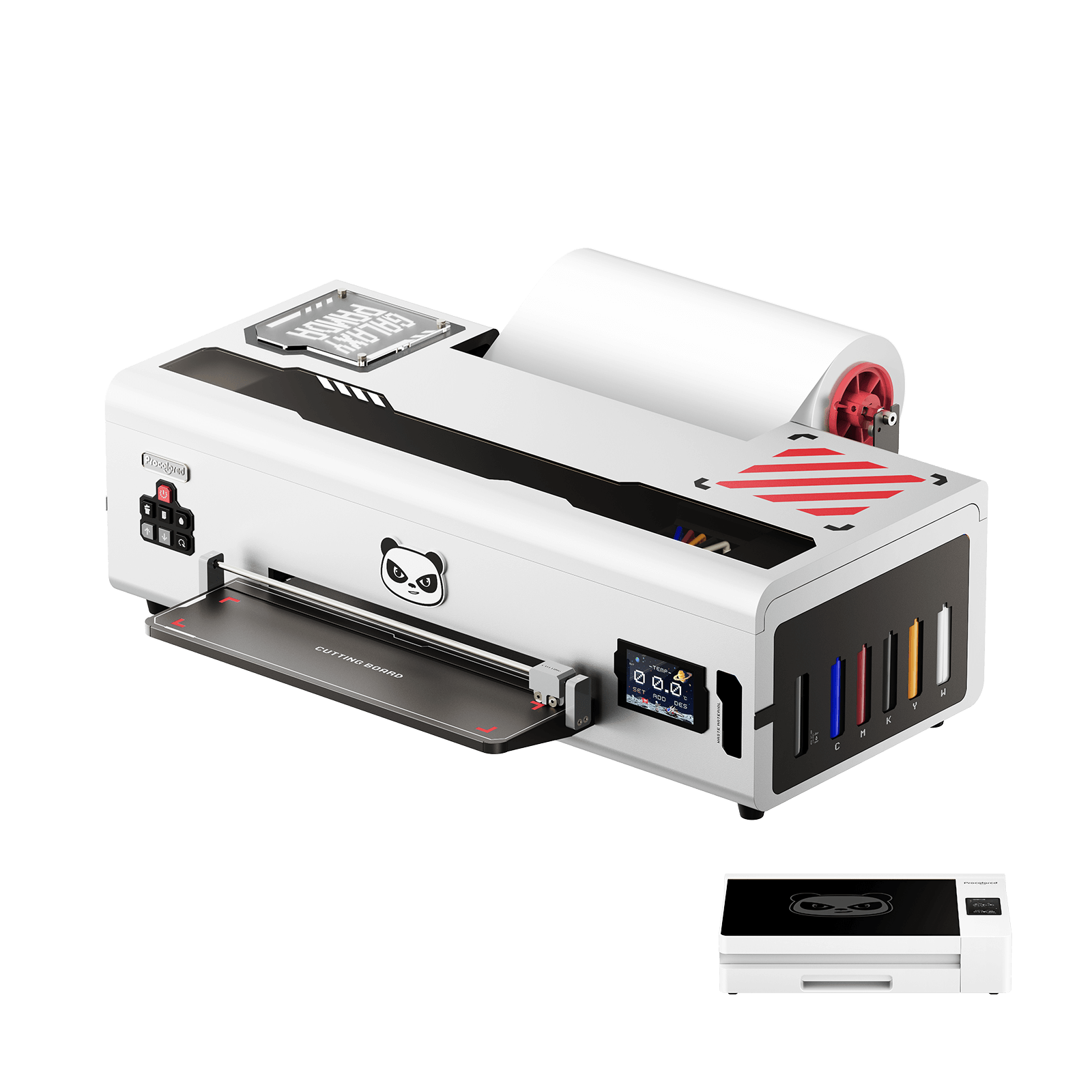

DTF ink, or direct-to-film ink, is a type of ink that is used to print designs directly onto a film. The film is then transferred onto a substrate, such as fabric or apparel, using a heat press or similar device. DTF ink is typically water-based or pigment-based and is designed to bond with the film and substrate to create a durable, long-lasting print. DTF ink is suitable for printing on a variety of substrates, including cotton, polyester, and other fabrics. DTF ink is very flexible, which makes it ideal for printing on stretchy or flexible materials. DTF ink is typically less expensive than UV ink and requires fewer specialized components or equipment to use.

In summary, UV ink and DTF ink are two different types of ink used for different printing applications. UV ink is ideal for printing on a wide variety of surfaces and is very durable, but requires a UV light source to cure the ink. DTF ink is ideal for printing on fabrics and other flexible materials and is less expensive and more flexible than UV ink.

DTF ink has the following characteristics

Vibrant colors: DTF ink is known for producing vibrant colors and sharp details.

Flexible: DTF ink is very flexible, which makes it ideal for printing on stretchy or flexible materials, such as sportswear or swimsuits.

Easy to use: DTF ink is easy to use and does not require any pre-treatment of the substrate.

Works with a variety of substrates: DTF ink is suitable for printing on a variety of substrates, including cotton, polyester, and other fabrics.

Cost-effective: DTF ink is typically less expensive than other types of ink, such as UV ink, and requires fewer specialized components or equipment to use.

Long-lasting: DTF ink produces prints that are long-lasting and resistant to fading, washing, and cracking.

In summary, DTF ink is a versatile and cost-effective ink that is ideal for printing on fabrics and other flexible materials. It produces vibrant colors, sharp details, and long-lasting prints, making it a popular choice for many printing applications.

Is white ink the most difficult case for DTF printers?

White ink in DTF printing can be more challenging to work with than other colors due to its unique properties. White ink is generally thicker and heavier than other colors, which can lead to some potential problems. Here are some of the common issues that may arise with white ink in DTF printing:

Clogging: White ink is more likely to clog the print head than other colors due to its thicker consistency.

Ink settling: White ink can settle in the ink lines or ink cartridges if the printer is not used for an extended period, which can lead to clogs or other issues.

Uneven printing: White ink may require multiple passes or higher ink volume to achieve the desired opacity, which can lead to uneven printing or smudging.

Ink adhesion issues: White ink may not bond as well with the film or substrate as other colors, leading to peeling or cracking of the print.

To avoid these problems, it is important to use high-quality white ink that is specifically designed for DTF printing. We have added a white ink stirring function to the DTF printer, which can regularly stir the ink in the white ink bottle, so that the white ink is in a uniform state. And we can also add white ink circulation function to the DTF machine, so that the white ink enters the ink tube first, and then circculates once before reaching the print head, so as to prevent the white ink from settling. And we plan to install a filter device for white ink to prevent large particles from clogging the print head

It is also essential to properly maintain the printer, perform regular cleaning and maintenance, and use the correct printer settings to ensure that the white ink is properly distributed and adheres to the substrate. With proper care and attention, white ink in DTF printing can produce high-quality, vibrant prints.