Title

Understanding Each Contender

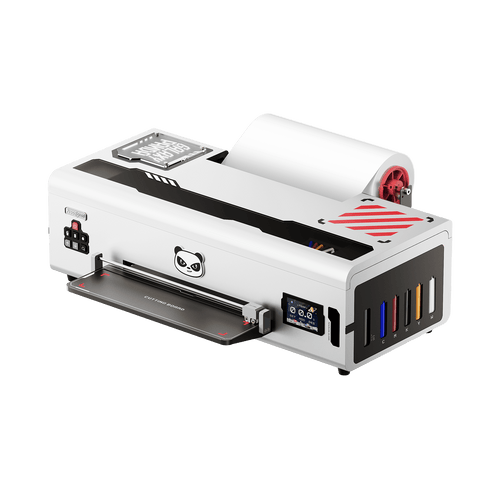

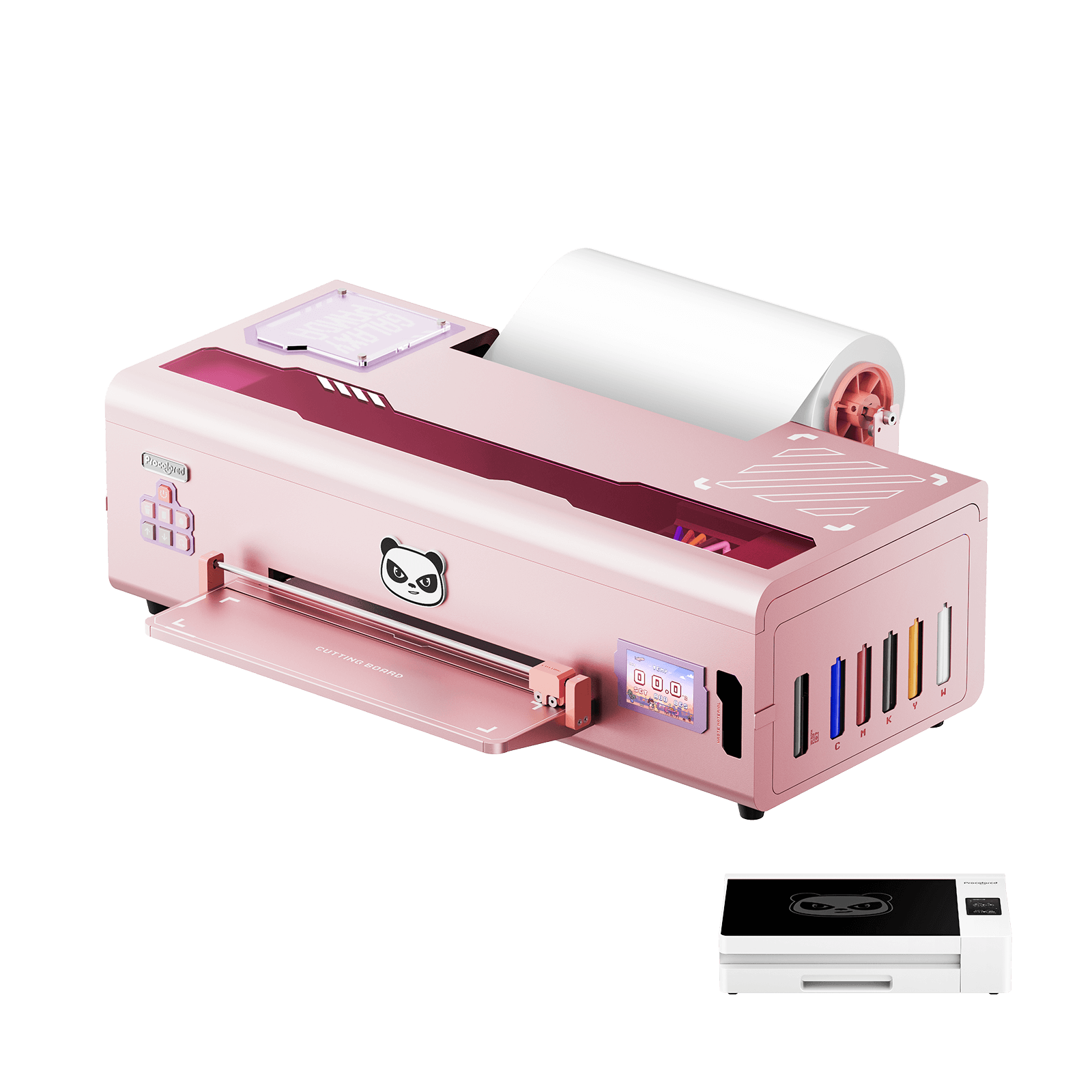

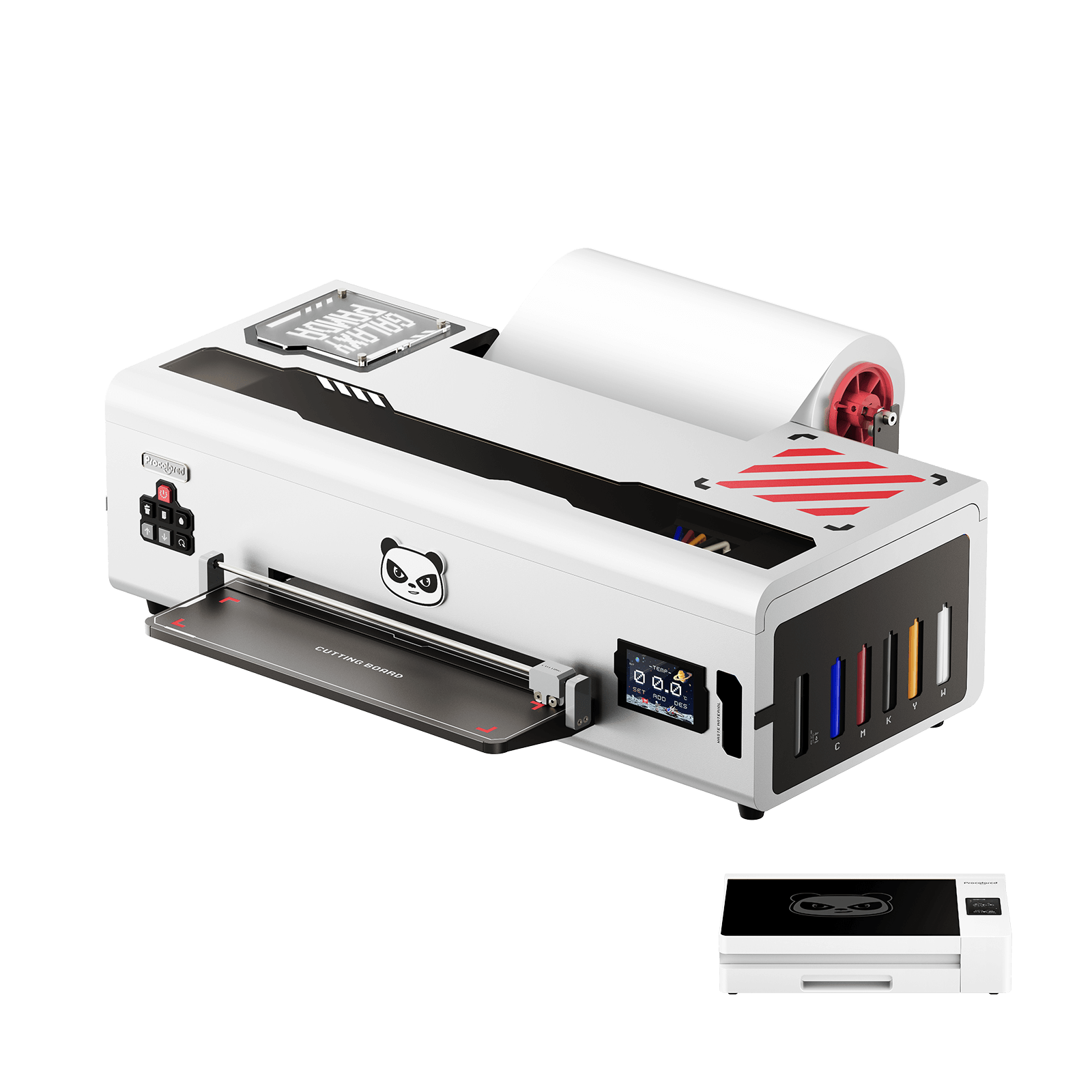

A. DTF (Direct-to-Film) – The Modern All-Rounder

B. Screen Printing – The Old-School Powerhouse

The Process – Behind the Magic

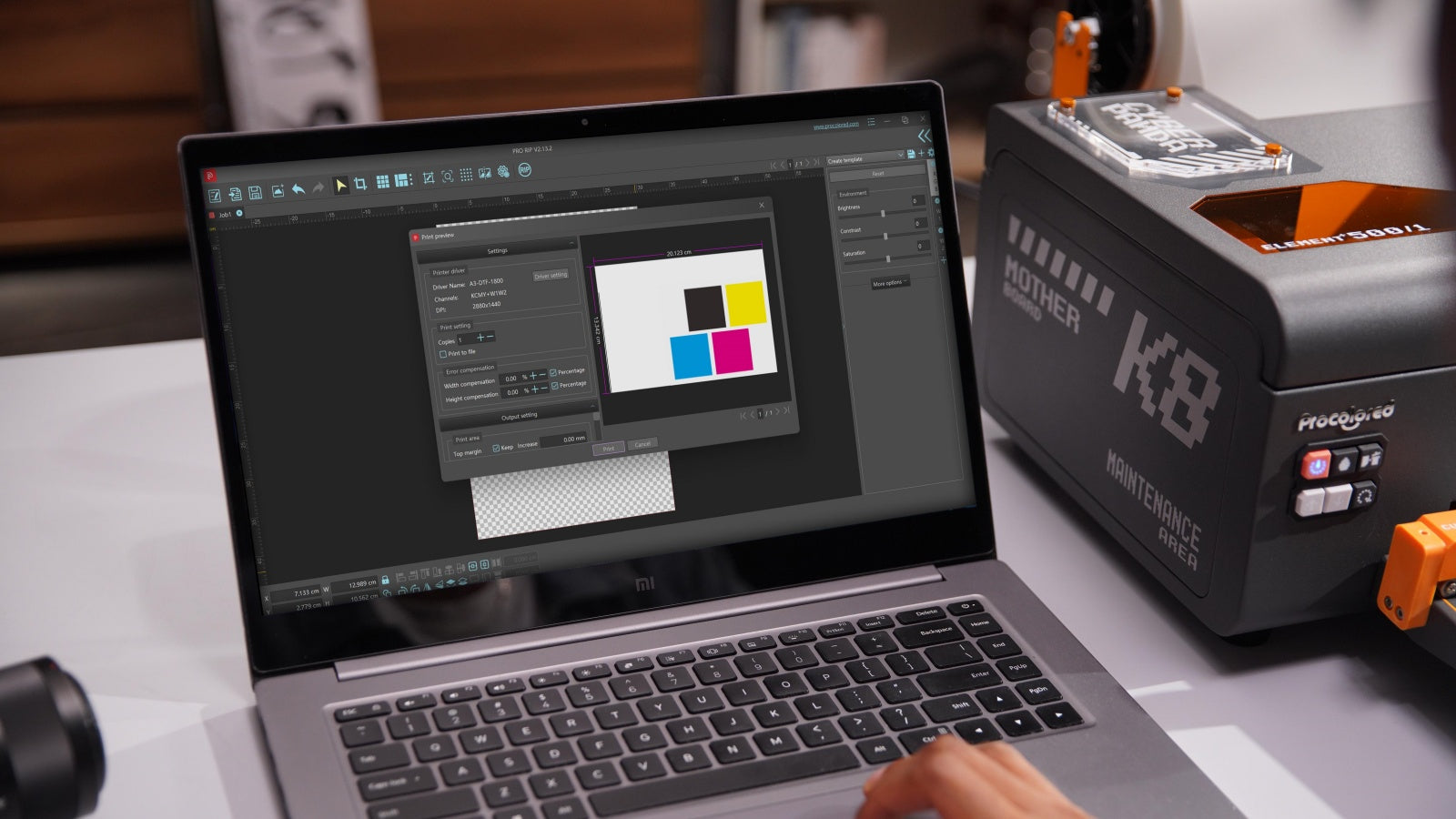

How DTF Works?

DTF vs. Screen Printing: Who Wins Where?

Image Quality & Detail

Fabric Friendliness

Speed & Flexibility

Feel & Finish

Durability

Environmental Impact – Who’s Greener?

DTF: Cleaner Setup, But Not Waste-Free

Screen Printing: Traditional Process with a Footprint

Pros & Cons (Recap)

Who Should Use What?

DTF Is Great For Your Business If You…

Screen Printing Is Your Weapon If You…