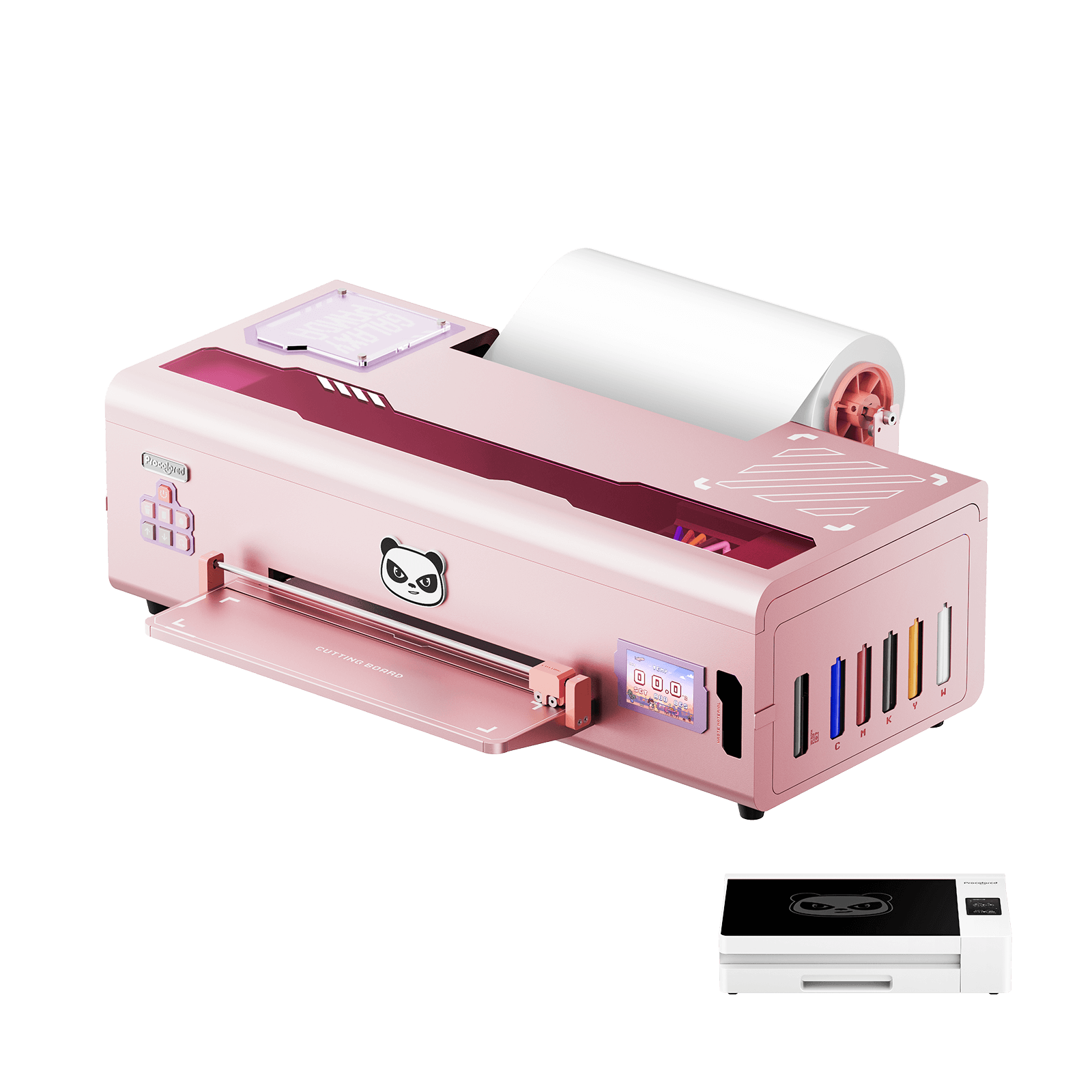

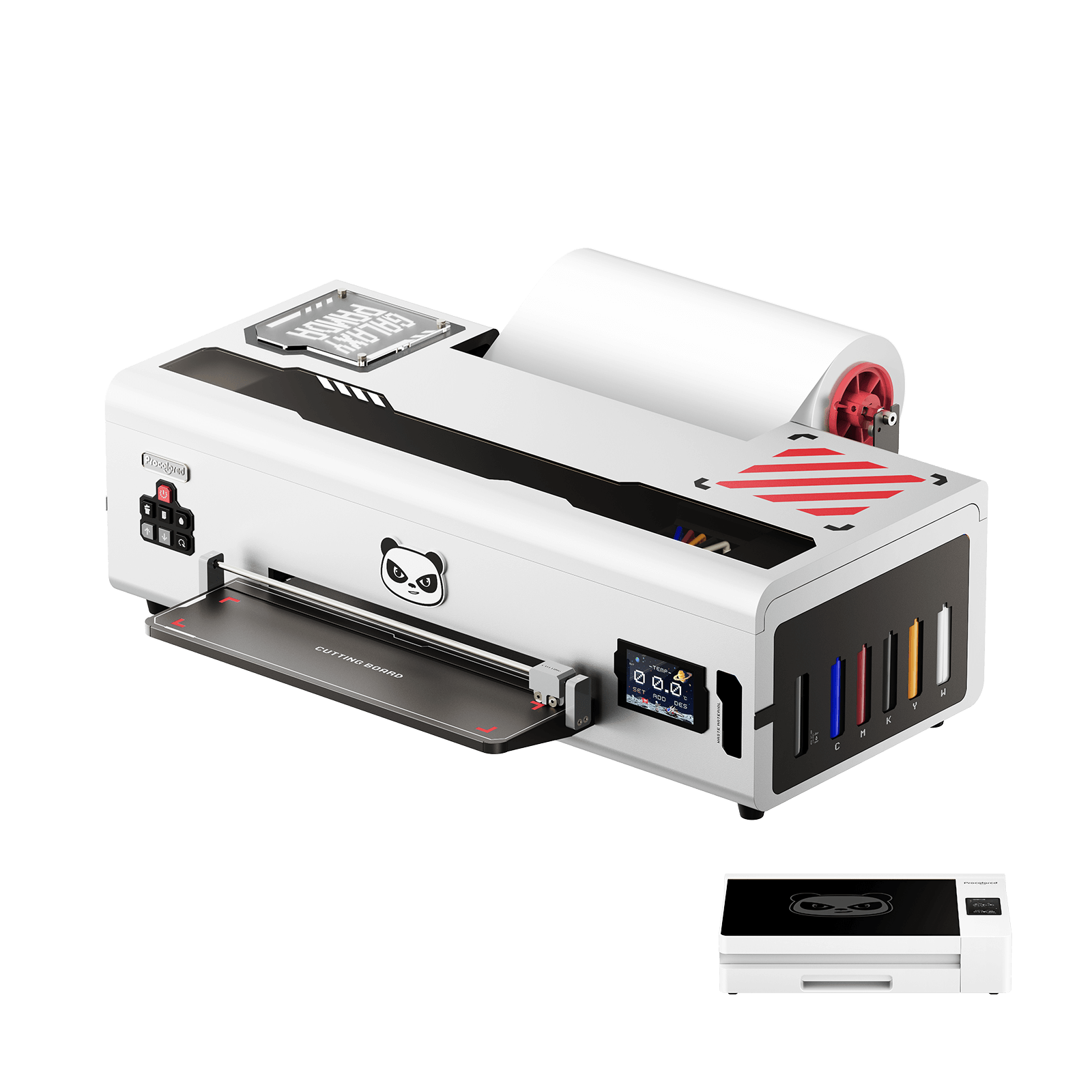

Printer Maintenance

To make sure the printer nozzles remain healthy status, we need to print out a check pattern and see whether the pattern is normal. This is a daily maintenance and it’s necessary to be done everyday.

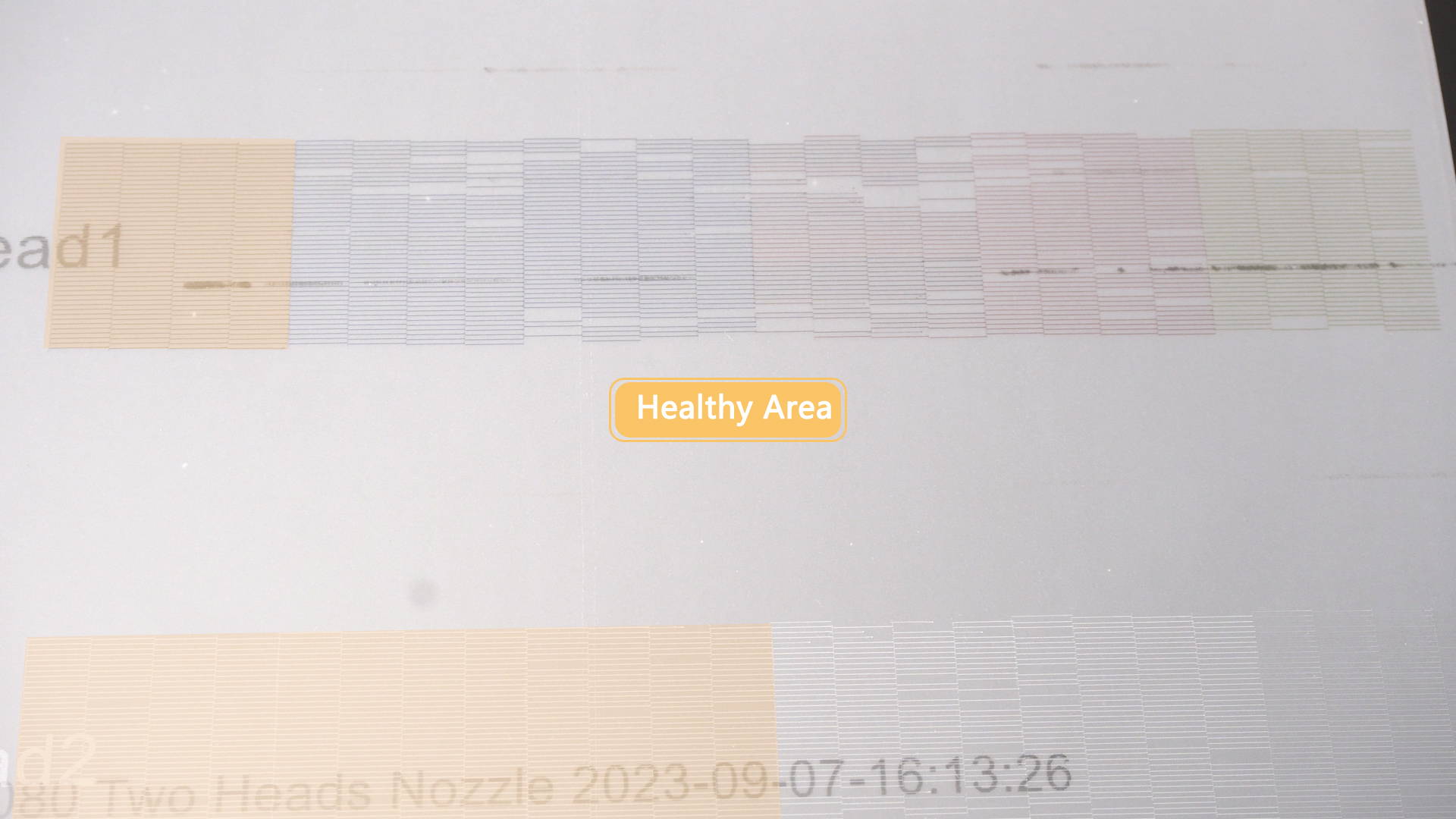

Check Pattern

The white check pattern is printed from the right side to the left. The lines of the white pattern gradually become clearer from the right to the left. This indicates that the print-head had a slight blockage at the beginning. As the nozzle gradually sprays ink during the printing process, the ink path of the nozzle gradually becomes unobstructed.

Nozzle Cleaning

Initiate the nozzle cleaning process. If the capping station is clogged, no ink will run out of the tubes. The white ink capping position is more likely to get clogged, so pay more attention to the white ink tube.

After the cleaning process is finished, press the test button on the printer to print out the check pattern. See whether is appearance of the pattern is getting better.

If the nozzles of the printer is slightly clogged, it should be cleaned as soon as possible. Some users want to manually flush the print-head when they found the ink paths is blocked badly and cannot be cleaned. Flush the print-head forcefully may reopen the ink path, but this practice is incorrect and will result in even greater losses. The micro-structure built inside the ink path can deform and crack under b strong pressure. If ink overflows from the ruptured ink path and flows onto the circuitry, it will cause damage to the circuit board. Therefore, daily maintenance is essential. Perform cleaning procedures everyday and ensure that the print-head remains in the closed position on the capping station to prevent ink evaporation and solidification.

Ink Waste Disposal

The next part is the regular maintenance. These actions are not doing everyday but they are also important. Empty the ink waste bottle when it is full up. When removing the bottle, hold a tray underneath it, in case some ink drips onto the floor.

Encoder Strip Cleaning

The encoder strip is a translucent plastic strip with small timing marks printed on it. It helps position the print-head assembly when the print-head carriage running on the guide rail. It needs to remain clean and clear to ensure precise and consistent printing. Dip some alcohol with a lint-free cloth and gently clean the plastic strip. Press the Left button to move the print-head assembly to the left, so we can clean the encoder strip on the other side. Click the Base Point button to return the print-head assembly to the capping station.

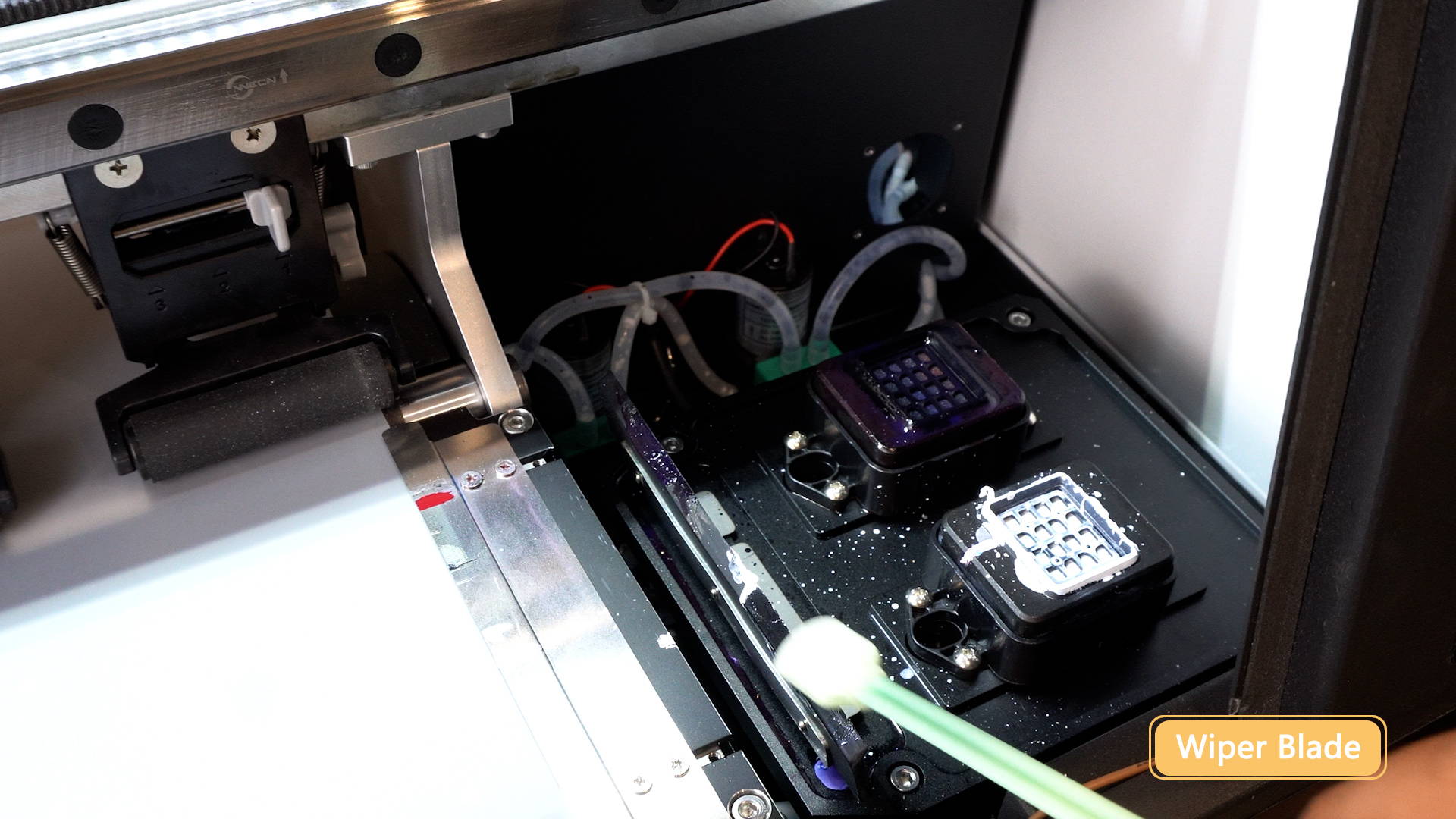

Wiper Blade Cleaning

When cleaning the the parking station, press the Left button to move out the print-head assembly. There is a wiper blade and 2 square caps on the parking station. Erase the ink residue with a lint-free swab.

The cleaning blade is to remove residual ink from the surface of the printer nozzles. The leftover ink on the nozzles could result in some unwanted marks on the printed film sheet.

Nozzles Cleaning

Move the ink cartridge carriage to the far left of the printer so that we can clean the print-head from its bottom. Wipe away the ink leftover with some lint-free cloth. Moisture the cloth with alcohol so that the ink residue can be washed away more easily. The print-head assembly can not leave away from capping station for a long time. Otherwise the inks inside the micro holes of the nozzles will get dry and block the ink path. When the printer is in idle status, the nozzles should be capped up to isolate air and keep moist. After cleaning, return the print-head carriage to its base point.

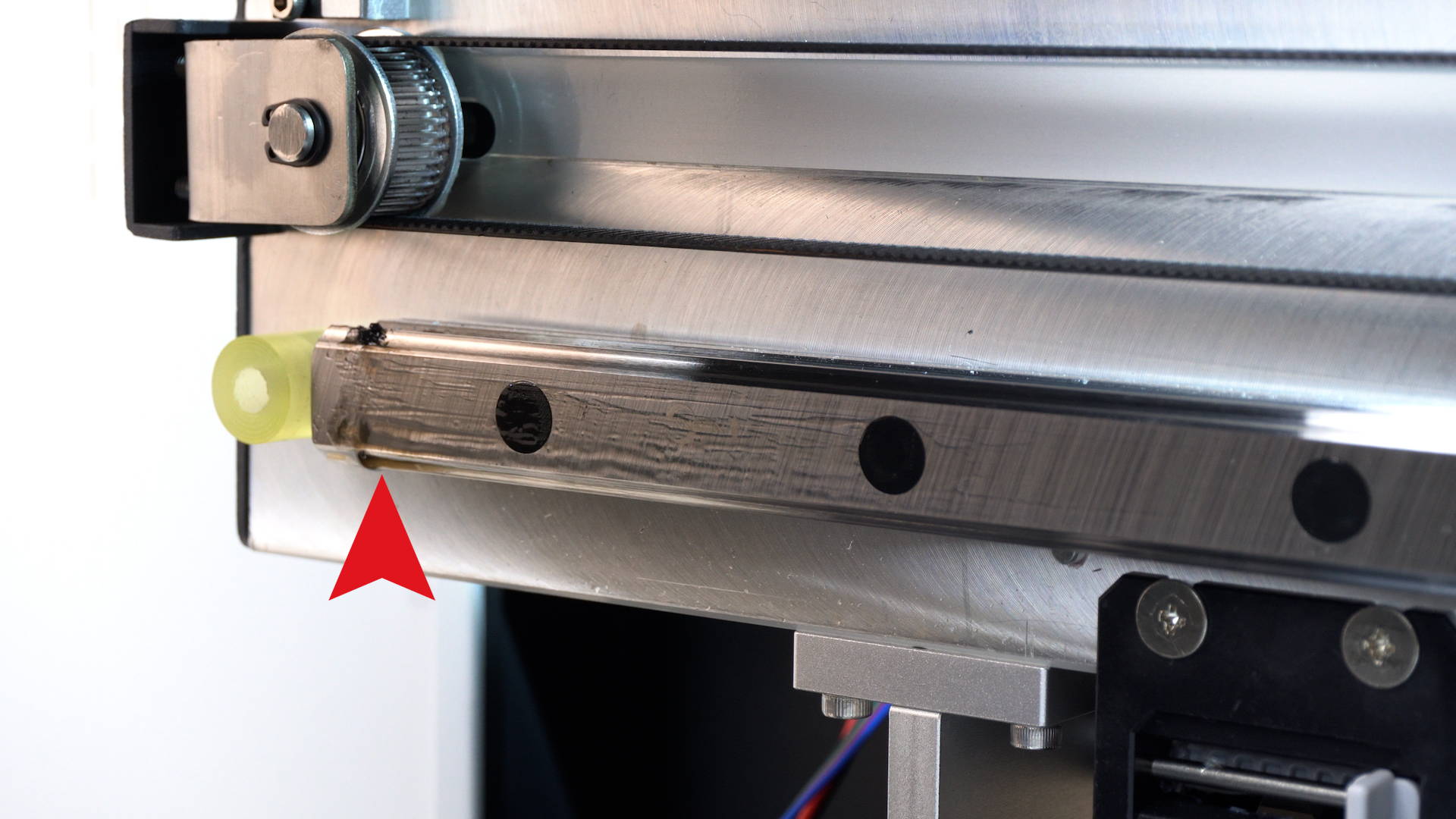

Guide Rail Lubrication

Grease lubricant can reduce friction between cartridge carriage and guide rail. Check out the lubrication of the guide rail regularly and make sure the carriage can move back and forth smoothly.

Printing Platform Cleaning

The last item is to clean up the printing platform. Withdraw the film sheet by pressing the Forward button. After cleaning, check out whether the film sheet can pass the printing platform stably without any tilting.