About DTF Technology

Direct-to-film (DTF) printing is a method of transferring images onto various surfaces, including cotton, polyester, blends, and other textiles materials. First, you need to send the print job to the printer using RIP (Raster Image Processor) software. Then, it is printed onto a specialized DTF transfer film. After waiting for inks to slightly dry and solidify, you add the addhesive powder on the print. Next, a curing oven is needed to heat the powder until it melts into a glue-like consistency. Then, you transfer the design from the transfer film onto the garment using a heat press machine, applying high temperature and pressure. Finally, a second heat pressing ensures proper adhesion, completing the production process.

Suitable Materials

The DTF (Direct-to-Film) printing process is suitable for a variety of materials, including textiles and non-textile substrates. The key factor is ensuring that the material can withstand the heat and pressure involved in the DTF transfer process. Here are some materials that are commonly used with DTF printing:

·Cotton

·Polyester

·Cotton-polyester blends

·Spandex

·Nylon

·Denim

·Canvas

Necessary Consumables:

DTF Ink

DTF ink is formulated to adhere to transfer films and facilitate the transfer of digital designs from the film onto various materials. Typically, there are five colors, CMYKW. It is common to print the image in reverse on the film. First, the colored layer is printed, and then a layer of white is printed to make the colors more vibrant. Therefore, the consumption rate of white ink is faster than that of other colors.

DTF Film

DTF film, also known as DTF transfer film, plays a crucial role in the DTF printing process. DTF film is a specialized type of transparent or semi-transparent film that serves as the medium for transferring digital designs or images onto various materials, primarily textiles and fabrics.

Adhesive Powder

Adhesive powder, in DTF (Direct-to-Film) printing, is a crucial component used to enhance the adhesion of printed designs from the DTF transfer film onto the textiles material.

DTF Workflow

Printing → Powder Application → Baking → Heat Press → Peeling → Second Heat Press

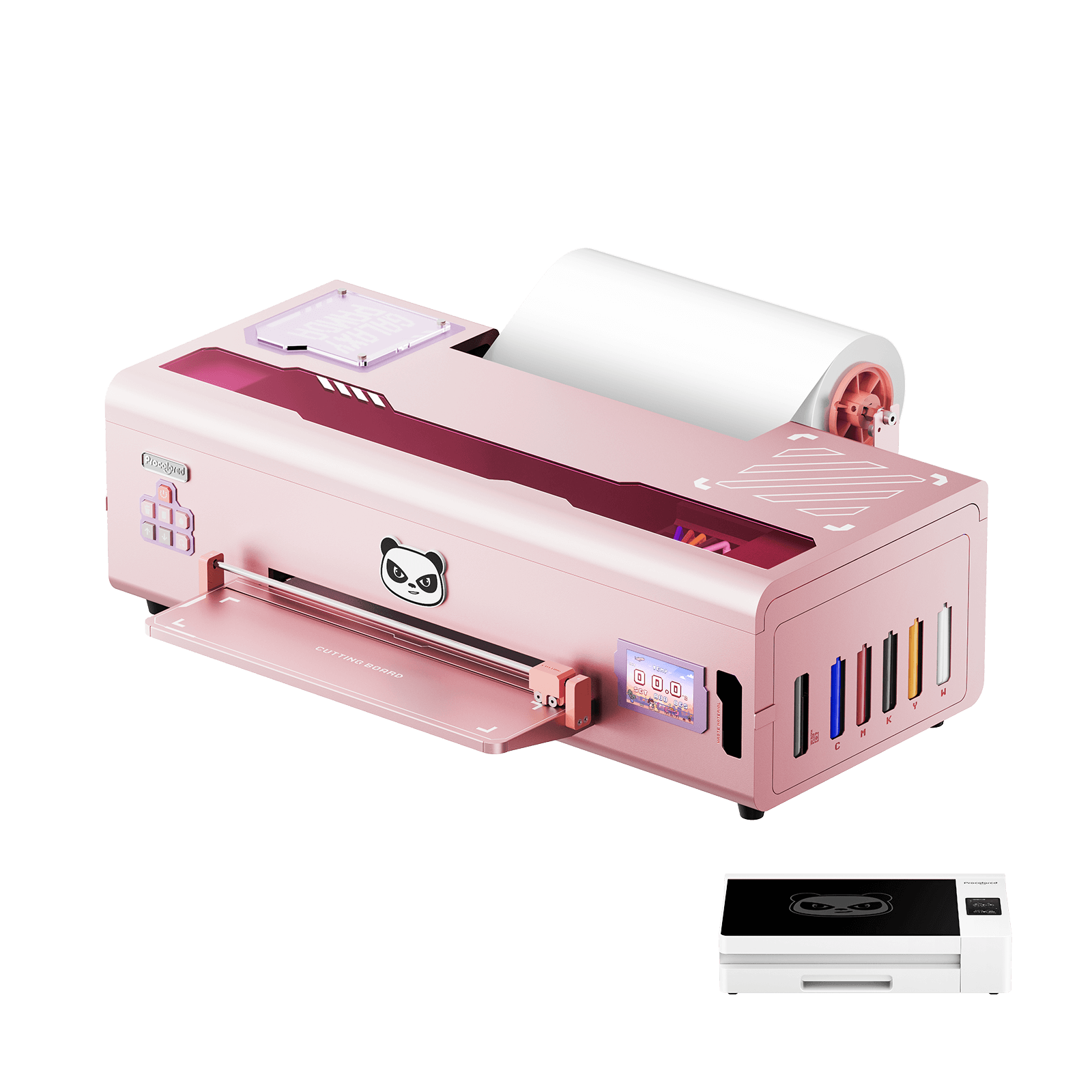

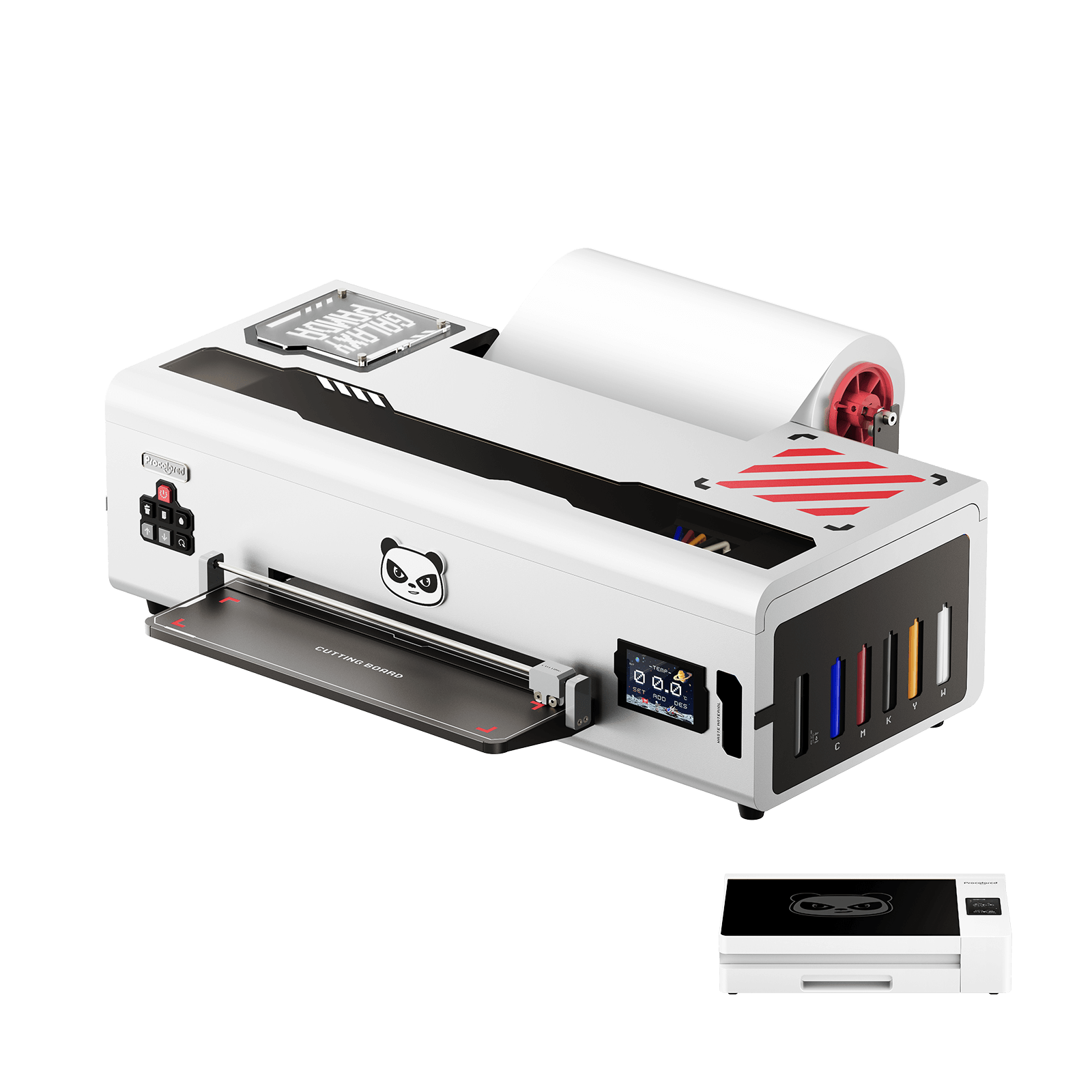

Product Comparison