Title

Table of Content

1. DTF vs Screen Printing – Which Is More Durable?

Understanding Durability Factors in Garment Printing

Core Metrics

Durability Testing Benchmarks:

2. DTF Printing: Durability Breakdown

Surface Layer Characteristics:

Wash Durability

Crack & Stretch Resistance:

Environmental Wear:

3. Screen Printing: Durability Breakdown

Ink That Merges With the Material

Wash Durability: Made to Last

Flexibility Against Crack & Stretch Resistance: Fits Movements Perfectly

Environmental Damages: Almost Weatherproof

Side-by-Side Durability Comparison

4. The Secret to Durable Prints? It’s The Perfect Application

DTF: Detail is Everything

Screen Printing: It’s All in the Cure

5. Real-World Performance Insights

Anecdotal Reports from Print Shop Owners and Users

Summary of Third Parties Durability Tests

6. How to Make DTF Prints Last Even Longer

✅ Recommended Guidelines

🚫 Things to Avoid with DTF Prints

7. Conclusion

Let's face it, there is nothing more frustrating than a printed t-shirt that looks extraordinary on day one but like a thrift store find on day ten. Whether you’re printing for a brand, business or simply for your own creative self, durability matters. If your design can't endure the hassle, washing, pulling, scrubs and real life activities, what is the POINT?

This brings us to two of the most hyped methods of printing techniques today - DTF (Direct to Film) vs screen printing; each with their positive traits. DTF is newer, highly versatile and excels in colorful, intricate prints. While screen printing stands as an old-school powerhouse—tried, tested, and trusted for decades.

But here comes the most important question: What lasts longer, Screen Printing or DTF? Which of the two methods withstands being put on, tossed into the wash, and worn again without fading, cracking, or peeling like some cheap sticker?

In this article, we are putting DTF transfer printer against screen printing and settling it for durability. If you are fed up with wondering and are ready to discover which one lasts longer, let’s dive in.

Before determining which method - DTF or screen printing - wears out first in the Durability battle, we must first look into the meaning of “durability” in the context of printed apparel.

Spoiler: It goes beyond enduring a couple of wash cycles.

So, what determines how durable a printed design will be? Here are some primary factors which help in making the distinction between “wow” versus “worn-out.”

● Wash Resistance:

This is an important one. A printed image should withstand high volumes of machine washing and maintain its color without ‘sidewalk’ cracking or shedding ink excessively.

● Stretch & Flex Resistance:

Let’s be honest, garments undergo movement. The chest of a t-shirt, or the knees of a hoodie, the entire range of printed areas should be able to stretch and flex without the design morphing into a brittle spiderweb.

● Adhesion to Fabric:

To what extent is the bond between the print and fabric? When it comes to screen printing, there is an injection of ink into the fabric which is not the case with DTF transfer printers, where a film is placed above the fabric. This disparity is very important regarding how stressed each method can last.

● Durability Withstands Persistent Use:

Everyday friction from wearing, washing, and folding can wear a design down. A long-lasting print would withstand months or years of actual use.

● Resistance To The Environment:

The heat coming from the dryer, sweat, and sunlight can all affect a print. The best printing methods shrug off UV rays, moisture, and heat without breaking a sweat.

Now, how do we actually measure all this? While not everyone runs a lab test on every shirt, there are some standard ways the industry tests durability:

● Wash Tests:

Tests of this category focus on how many washing cycles can be done without any print degradation. Most quality prints tend to survive at least 40–50 washes — more is better.

● Stretch Testing:

This test focuses on stretching parts of the print repeatedly to see how well it rebounds. A crack is considered the mark of defeat.

● UV Fade Testing:

Simulated exposure to sunlight shows how well the print resists fading over time—this is particularly helpful for outdoor clothing and uniforms.

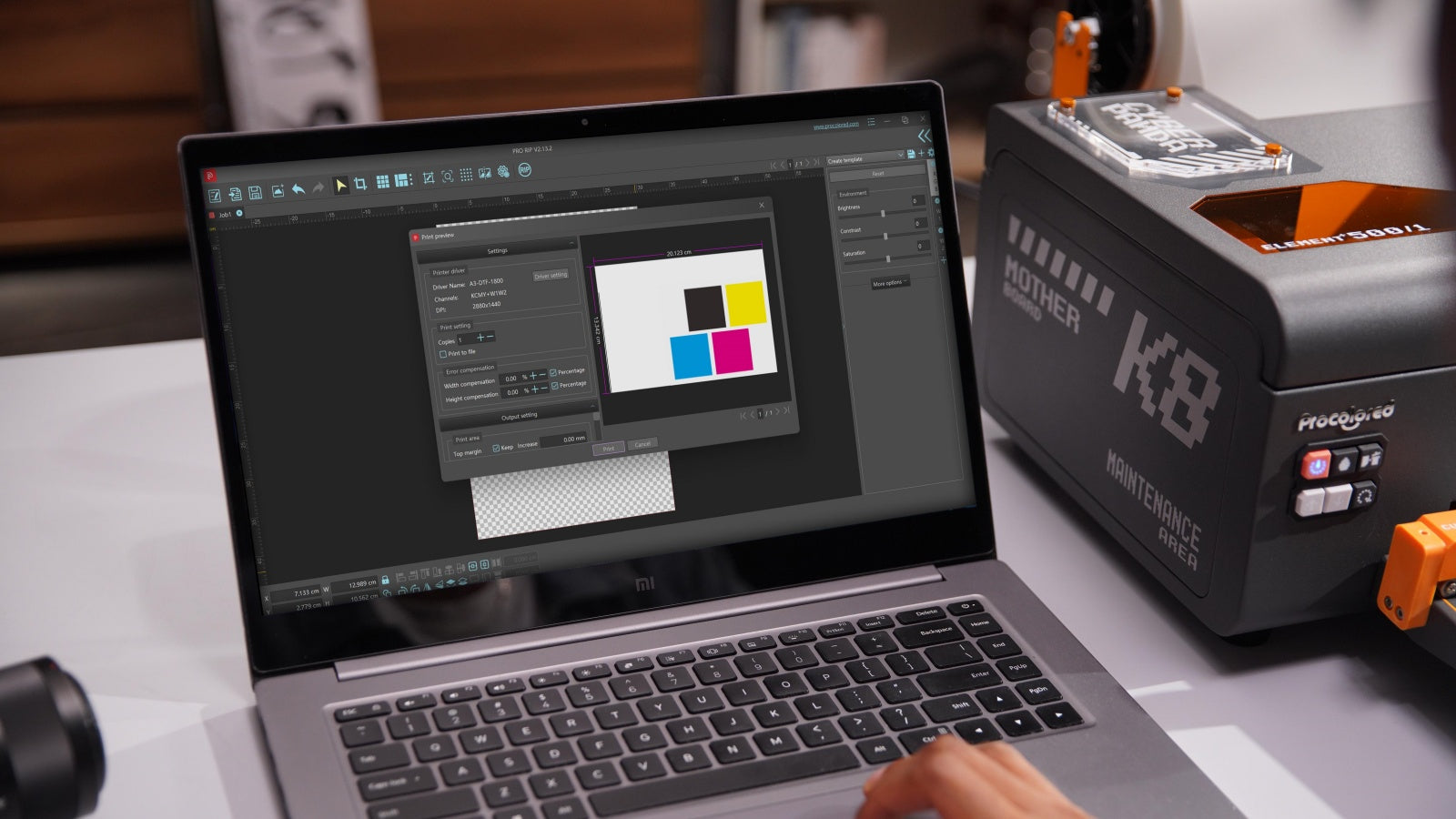

DTF printing, or Direct to Film printer, is revolutionizing the custom apparel industry for good reason. It is colorful, vibrant, works on many types of fabrics, and is quite flexible compared to other methods. But what is the claimed DTF durability level? Let's explore that.

The first thing to consider about DTF is how it interacts with the fabric. Unlike screen printing where ink soaks into the fibers of the fabric, DTF film utilizes a heat press transfer technique. The design or print is placed on a film which sits on top of material and pressed to form film covering the fabric.

The key is the right process—perfect temperature, right amount of pressure, and the right speed. When done right (especially with a high-quality setup like a Procolored DTF machine), the result is a solid, well-adhered print that holds strong wash after wash.

A well pressed DTF prints can withstand around 40 to 50 washes before they start showing signs of wear. That’s pretty solid for fashion wear that isn't worn everyday.

With proper aftercare such as cold washing and low heat drying, Many users report even improved longevity.

Of course, subpar application can lead to undesirable peeling or flaking, which is easily avoided with a proper DTF machine and correct pressing temperatures. A bit of attention with the technique and DTF prints will hold up astonishingly well over time.

DTF performs well under stretches as well. Moderate stretch doesn’t lead to cracking, especially when applied to more stable fabric regions. While heavy stretching (such as across the chest or back) may lead to some cracking, this tends to happen only after extended use or extreme wear. Even then, the damage is often negligible and void of immediate noticeable effects.

For everyday wear, especially in fashion or casual apparel, DTF printing machine proves itself to be surprisingly good in retaining flexibility.

In terms of environmental stress, DTF printers offer decent UV and moisture resistance. It doesn’t fade easily in the sun and mild heat or sweat is manageable. While extreme heat and prolonged exposure seem to reduce flexibility, it’s not an issue with everyday use.

Because the design is printed on top of the fabric, it might be less breathable when compared to screen printing where ink is absorbed into the material. Still, this is a small compromise for the color detail and sharp vibrancy that DTF machines provide— and for many users, it’s a deal breaker.

If DTF is the new sensational method everyone is raving about, screen printing is the veteran who’s an experienced expert. Used for years, it’s still one of the most reliable ways to print on clothes. And when it comes to making prints that last screen printing truly excels. Let’s examine why it is still the go-to method for strong, long-lasting designs.

What truly makes screen printing unique is how it fuses with the garment. Rather than just sitting on top as in DTF, the ink is pushed deep into the fabric’s face and becomes part of the textile. This results in a print that is more integrated, flexible, breathable, and; most importantly, moves naturally with the garment.

Screen printing, when done right, can withstand 50-100+ (yes right, a 100 washes) without losing its sharpness and color. It is the most trusted for workwear, athletic gear, and merch that need to go the distance.

Inks like plastisol are especially tough, keeping their bold look for years, while water-based and discharge inks age gracefully, often becoming softer without losing the artwork’s clarity.

Unlike direct-to-garment printing, screen printing causes an embedded design to crack less because the ink is not resting on top of the fabric, it is within. Furthermore, with the use of appropriate ink formulas such as stretchable plastisol, movements in high-flex areas such as knees, elbows, and shoulders are well upheld.

As long as the print is cured correctly (for example, baked at a specific temperature), it remains smooth and strong, even when put under stress.

Sun? Sweat? Heat? No problem. The use of water-based or discharge inks makes screen printing resistant to harsh elements. Not only do these inks withstand UV rays from sunlight and moisture, they also make the garment more breathable, which is perfect for outdoor apparel, uniforms, or any clothing exposed to harsh conditions.

In other words, if your design is going to see a lot of sun, sweat, or heat, screen printing has you covered.

Durability Factor

DTF Printing

Screen Printing

Wash Longevity

~40–50 washes

50–100+ washes

Peel/Crack Resistance

Moderate (film may peel/crack)

High (inks bonded to fibers)

Stretch Performance

Fair; can crack over time

Excellent, especially with flexible inks

UV/Heat Resistance

Moderate

High

1Ideal for Heavy Use?

No – best for casual/lightwear

Yes – workwear, sportswear, etc.

No matter how effective a printing technique may be, it is unable to achieve its maximum potential if not implemented in a proper manner. Regarding durability, design application onto the fabric holds equal importance as the method selection. Let’s simplify it:

DTF: Detail is Everything

From the outside, DTF printing might look straightforward, but the execution is quite sensitive. If the press, temperature, pressure, or timing of the peel is even the slightest bit off, it can significantly alter the outcome.

What Happens If:

●Is the press too cold? The film will not adhere.

●Over applied or under-applied pressure? Early self-peeling.

●Film peel done too early? The design will not stick in any case.

Bottom Line: DTF is only as strong as the press job. If all steps are followed, DTF withstands dozens of washes. On the other hand, if the process is hurried with no time for attention to detail, misalignment can occur with the printing or the image begins to fade or peel after only a few uses.

Screen Printing: It’s All in the Cure

With screen printing, durability depends a lot on curing—that’s the process of binding the ink to a fabric through heating. If the curing is executed well, the print will integrate with the shirt. If it is not, peeling, fading, and early wear out will occur.

Things Matter:

●Ink kind: Plastisol, water-based, or discharge, each cure differently

●Curing temperatures and timing: If too low or cut short, the ink becomes soft.

●Fabric cleanup: Dusty or greasy fabrics will greatly impact the bonding of the ink.

The positive Aspect? As long as it's properly cured, screen printing becomes incredibly tough, even in heavy use and frequent washes.

Real-World Performance Insights

Anecdotal Reports from Print Shop Owners and Users

Owners of print shops who have adopted DTF machines—especially with reliable machines like the Procolored DTF printer— have shared their insights towards DTF and praise its efficiency, vibrant output, and strong durability across various fabrics. They appreciate how DTF removes the need of screens or complex setups, just clean, consistent results.

According to multiple users, with the correct application, their DTF prints last through 40 to 50+ washes with little to no fading. Meanwhile, Traditional screen printers still defend longevity and toughness, especially with bulk orders and work wear. However, they also mention higher setup time, few color selections, and complex artwork which DTF solves seamlessly.

Summary of Third Parties Durability Tests

Third-party testing indicates that screen printing can last over 100 washes provided the inks are cured properly and the garments are well taken care of.

However, DTF technology is rapidly closing the gap. Modern DTF printers, especially with Procolored’s siphon circulation and advanced ink circulation, are known to maintain color, bond, and flexibility for over 40–50 washes. That is sufficient for any custom apparel, fashion capsules, or event merchandise.

The convenience and reliability of DTF printing alongside its increasing resistance to washing, UV light, and heat make it a worthy contender in the durability arena.

How to Make DTF Prints Last Even Longer

✅ Recommended Guidelines

●Wait for the first wash for 24 to 48 hours as this gives enough time for the adhesive to set into the fabric.

●Turn garments inside out to protect the print from getting in touch with detergent and friction.

●Use cold or lukewarm water as hot water can weaken the adhesive leading to cracks or fading.

●Use mild detergents that aren’t abrasive.

●Wash on a gentle cycle as this lowers the mechanical impact to the printed areas, leading to lower stress.

●Wherever possible air dry. Extremely hot temperatures from the dryer can harm the film, if needed, use low heat only .

🚫 Things to Avoid with DTF Prints

●Avoid high-temperature tumble drying–The film can soften, crack or peel from over-exposure to excessive heat.

●Avoid using fabric softeners – They leave a residue that breakdown the adhesive

●Do not iron directly onto the print – If necessary, use cloth or parchment paper over the design.

●Do not dry-clean DTF garments – the solvents used can destroy both the adhesive and ink.

●Avoid wringing or stretching printed areas – Over time this type of stress causes cracking.

Conclusion

So, from the durability test, we’ve seen both screen printing and DTF print withstand the test—but in different manners. Screen printing continues to be a crowd favorite for its stunning durability surpassing 100+ washes when properly cured.

DTF printing, on the other hand, proves itself to be the modern, flexible, and user-friendly option, especially when backed by top-tier technology like the Procolored DTF printing machines.

DTF prints offer resistance against fading and stretching while ensuring clean adhesion across numerous fabric types. With the combination of speed, meticulous detail, and ease of setup, it is no surprise that many print shops align with DTF as their method of t shirt printing.

If you are looking for a solution with sturdy, high-performance, durable printing built for today's demands, the Procolored best DTF printer easily stands out as the most logical choice. So, elevate your print quality, versatility and durability with Procolored today.

Most Popular Blogs

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

Most Popular Blogs

Your cart is currently empty.

Start Shopping$1,099