“Help! Why the ink color ain’t never right?”

We’ve received some messages questioning this issue.

The truth is, no printer producers dare to guarantee an exact 100% color reproduction.

The reason is, our beloved colors are colorful, meaning they can be really, really changeable.

How so? Scroll down to find that out!

PASSAGE SUMMARY

1. Why there’s always color deviation?

We’ve heard people saying that “this isn’t the right color” all the time. But which one should be defined as the right or the correct one? The one on you mobile phone screen, or on computer monitor? The one on your Macbook, or on your Dell?

HP and Microsoft cooperatively created standard RGB (red, green, blue) color space in 1996. Subsequently it was standardized by International Electrotechnical Commission (IEC) and has been widely used for defining web and image color space since then.

Yet with much more cutting-edge display technology and computer configuration as strong back-ups, color space has gained great development - sRGB is not the only unique favorite any more, there comes Adobe RGB, ProPhoto RGB and so forth color spaces to meet the gradually professional needs. Hence, colors become much more changeable.

And things get more complicated when these colors are needed to be printed out correctly - the colors presented can be greatly affected by the printer color space, printing ink quality or even the substrates going to be printed on.

To be more specific, below factors might cause color deviation in your printed images:

Incompatible color spaces - When a printer receives a printing task, it will do corresponding calibrations and profiling within its limits to meet the image’s color space. If the image has a wider color gamut than the printer can reproduce, the printer will only print out what’s the most approximate (which seems color-deviated to us).

Malfunctioning machine - Clogged or partially blocked print heads can lead to uneven distribution of ink, resulting in color inconsistencies.

Improper printed substrates - Different substrates absorb ink differently, using improper printed substrates may lead to color shifts and create evident color deviation.

Improper temperature and humidity - The ink absorption and thickness can be greatly impacted by the working temperature and humidity.

Ink issues - Expired or improperly stored ink can cause changes in color properties; low ink levels affects ink saturation and especially performance of gradient colors; improper ink may degrade the printing output and cause nozzle clogging or blockage.

2. How Do Ink and Printer Conform with Each Other?

Among all the factors provided above, ink issues might be the most common reason for the color-deviation complaints. During the mediation process, we’ve noticed that some customers had replaced Procolored inks with other cheaper DTF inks for budget concerns, and it did finally cause conformance problems. This may not be the ordinary situation but still, it super matters to understand how ink and printer exactly work with each other.

Let’s first take a closer look at printing ink. Printing ink in most ways are similar to other inks, they are all made of colorants and liquid carriers, are all endowed with viscosity and adhesion, and are all in need of further drying and curing. However, for printing ink, working with a printer means a lot of extra tests needed, including but not limited to:

Chemical compatibility - As mentioned above, printing ink is a kind of chemical combination that can react with specific materials. Hence, a set of professional tests must be taken first to avoid any accidental reaction between ink and printer components.

Ink level sensing - The working principle of ink level sensing can differ from different printers, but they are mainly forecasts based on the matched printing ink’s performance, including drying speed or the usage of per printing. Inproper inks provide incompatible performances and might lead to false low-ink warnings or failing to recognize when a cartridge is full.

Drying time - This includes two major dimensions : a) the ink drying speed on paper/film/fabric, to which the printing speed of a printer is programmed to align; b) the ink drying speed on printer components - if the ink dry too quickly inside the print head, the risk of clogging may be increased.

Adhesion to media - Printing inks are designed to perfectly meet their target carriers like paper, film, fabric or even plastic. However, though they are suitable for the same material, their viscosity can be quite different. Especially for printing method like DTF printing - among the matched printing ink, film and adhesive powder, there’s already an customized interreaction. Changing any one of them might produce printings with poorer adhesion and bonding.

It’s clear to notice that apart from their unchangeable nature, printing ink and printer are specially configured to better fit each other. Some cheaper inks seem to be the perfect substitute, but most of them only share the same chemical components with the original ones. When it comes to drying speed, degree of adhesion or compatibility with other consumables like film or adhesive powder, they might bring you inevitable trouble.

3. How to Alleviate Color Deviation?

So in what ways can we effectively alleviate the color-deviation situation? The following measures might be helpful:

Use original or genuine ink - Think twice before you insert the substitute ink into you printer. Improper ink may cause irreversible harms to your printer components and lead to inaccurate color presentation.

Degrade the color space of your image - Generally speaking, most printers nowadays still fail to restore exclusively elaborate color ranges. By degrading the color spaces and profiles in the design software, your image or graphic would be much more easily transformed by the printer.

Periodic printer maintenance - Regular print head cleaning can help you discover any nozzle clogging or malfunction in time, thus reducing color-deviation issues.

Regular calibration - Use LCC profiles to calibrate your monitor, printer and RIP (Raster Image Processor) software, to avoid color inconsistency caused by printer aging, environmental changes, or ink/paper variations.

Tips especially for Procolored users -

Curve setting - Wrong curve setting in RIP software can lead to serious color deviation. To avoid that, Procolored provides tutorial videos for all products (stored in a white USB flash driver, sent together with your machine). Remember that each curve only serves for one specific printer, do follow the corresponding videos to set the correct curve.

Find curve setting here: RIP software - Printer Management

Install Printer - Several printer curves provided here, if you can’t find your printer, then ↓

Import Printer - Follow our tutorial videos to import the correct curve for you printer

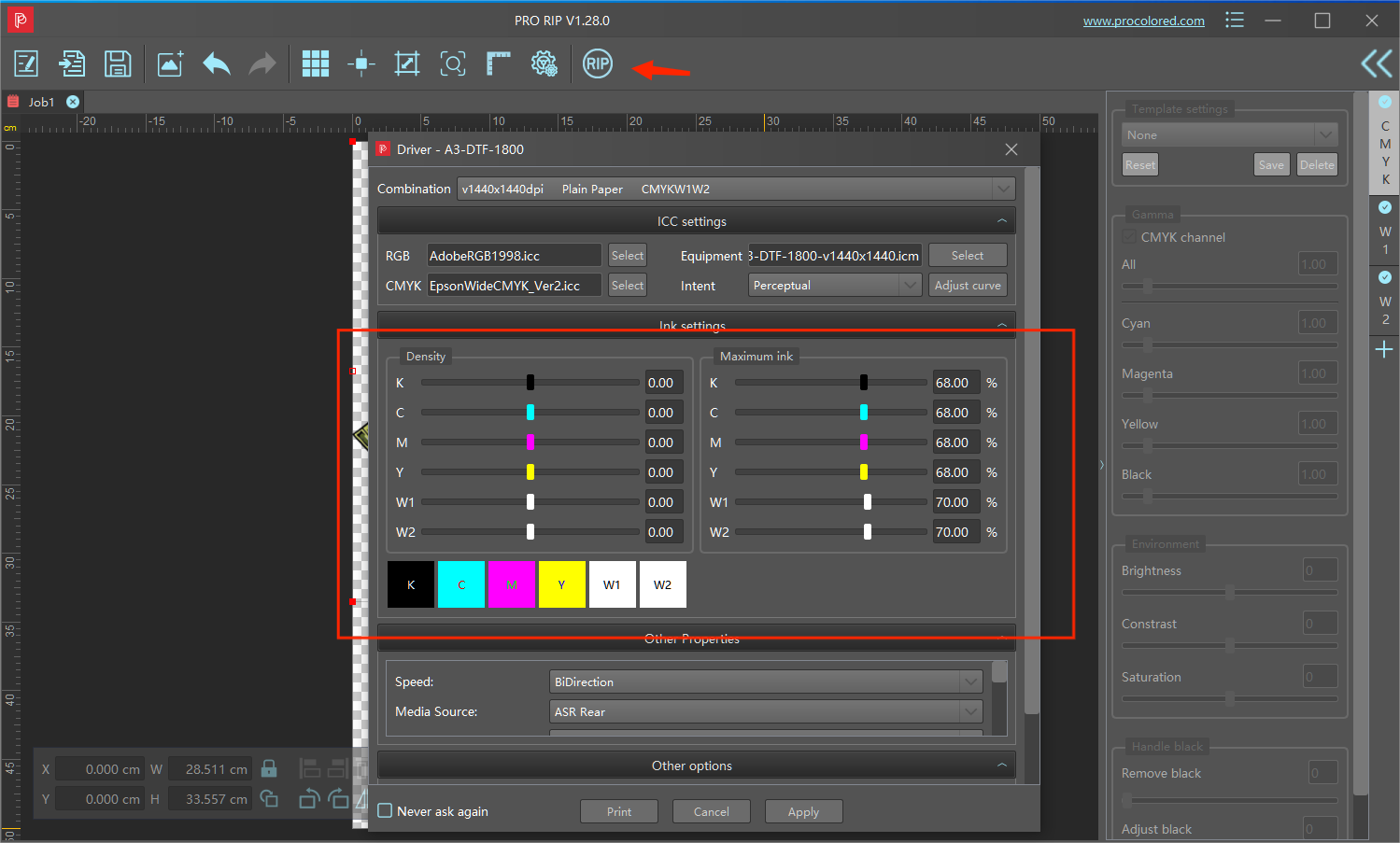

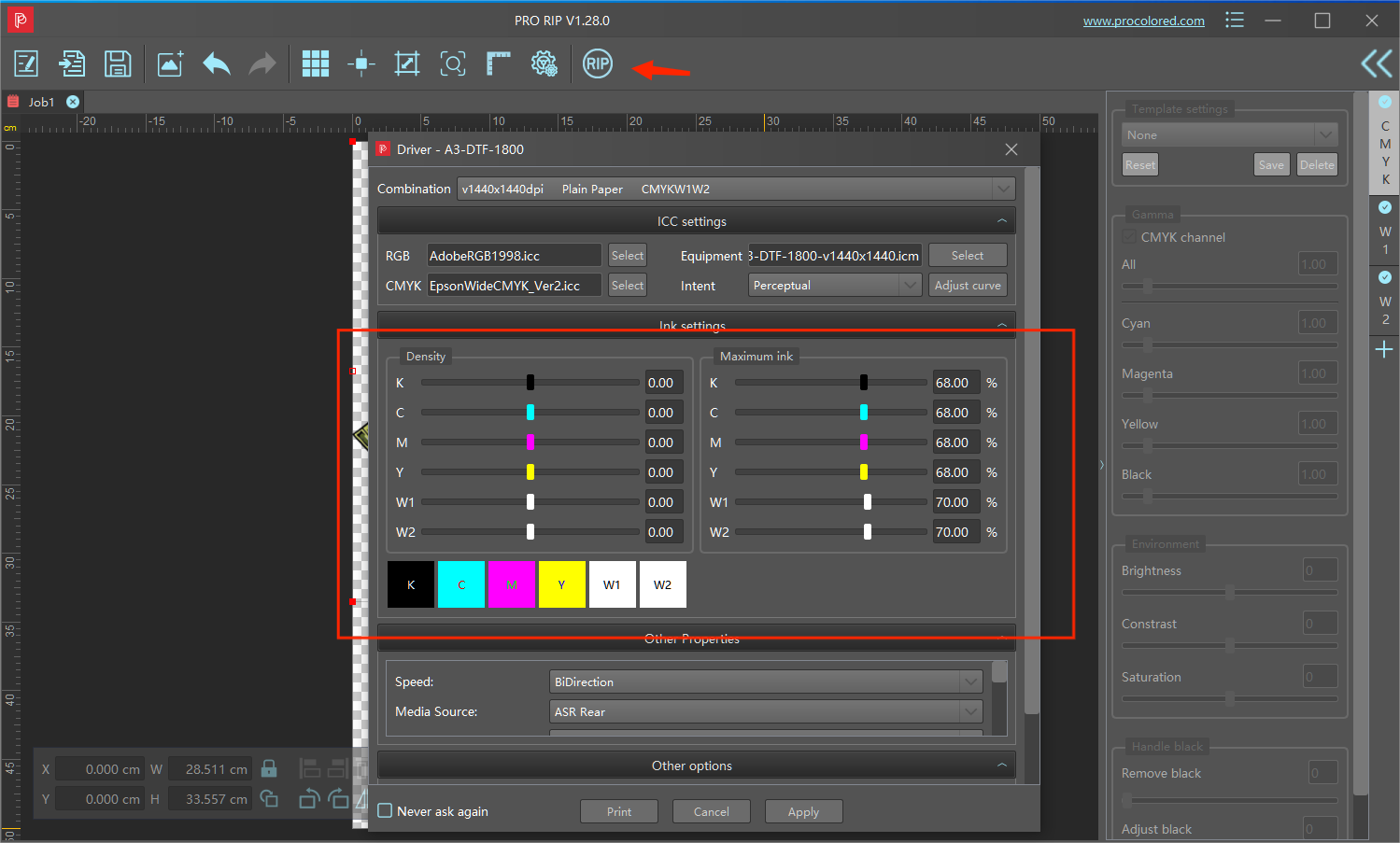

RIP color setting - Improper color settings in RIP software may also incur color inconsistency. Every time when we import the graphic and click RIP to proceed the printing, there’s a window popping up like this:

These color setting are defaulted values set by the Procolored tech team, it can not be back to default once being changed.

If you’ve changed the values by mistake and there’s color deviation occurring, please contact our customer services to restore it.

Curve setting - Wrong curve setting in RIP software can lead to serious color deviation. To avoid that, Procolored provides tutorial videos for all products (stored in a white USB flash driver, sent together with your machine). Remember that each curve only serves for one specific printer, do follow the corresponding videos to set the correct curve.

Find curve setting here: RIP software - Printer Management

Install Printer - Several printer curves provided here, if you can’t find your printer, then ↓

Import Printer - Follow our tutorial videos to import the correct curve for you printer

RIP color setting - Improper color settings in RIP software may also incur color inconsistency. Every time when we import the graphic and click RIP to proceed the printing, there’s a window popping up like this:

These color setting are defaulted values set by the Procolored tech team, it can not be back to default once being changed.

If you’ve changed the values by mistake and there’s color deviation occurring, please contact our customer services to restore it.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!