The lifespan of a shirt is often associated with the type of cloth used—be it 100% cotton, polyester, or a blend. However, the more overlooked, but equally important, aspect is the PRINT.

One could argue that a garment can last for several years and remain structurally sound, but if the print on the front is cracked, faded, or peeling, it feels “unwearable” long before the fabric completely gives out.

This is because of the reason below:

● Surface vs Integration.

Vinyl heat printing, along with other lesser-quality sublimation printers, are cheaper printing methods that tend to float on top of the fabric. This is then developed into a layer that is unable to flex with the fabric. After a series of prolonged washes, drying, and stretching, the prints tend to crack and peel off.

● Color Retention.

We all know how traditional inks do not properly penetrate into the fabric. As a result, the color looks bright at first but when they’re exposed under detergents, sunshine, and various washing cycles, color fades considerably.

● Wear Balance.

The fabric and print should be able to last and age together. In the scenario where the fabric ages more than the print, you are left with a perfectly good shirt but it no longer looks good or desirable.

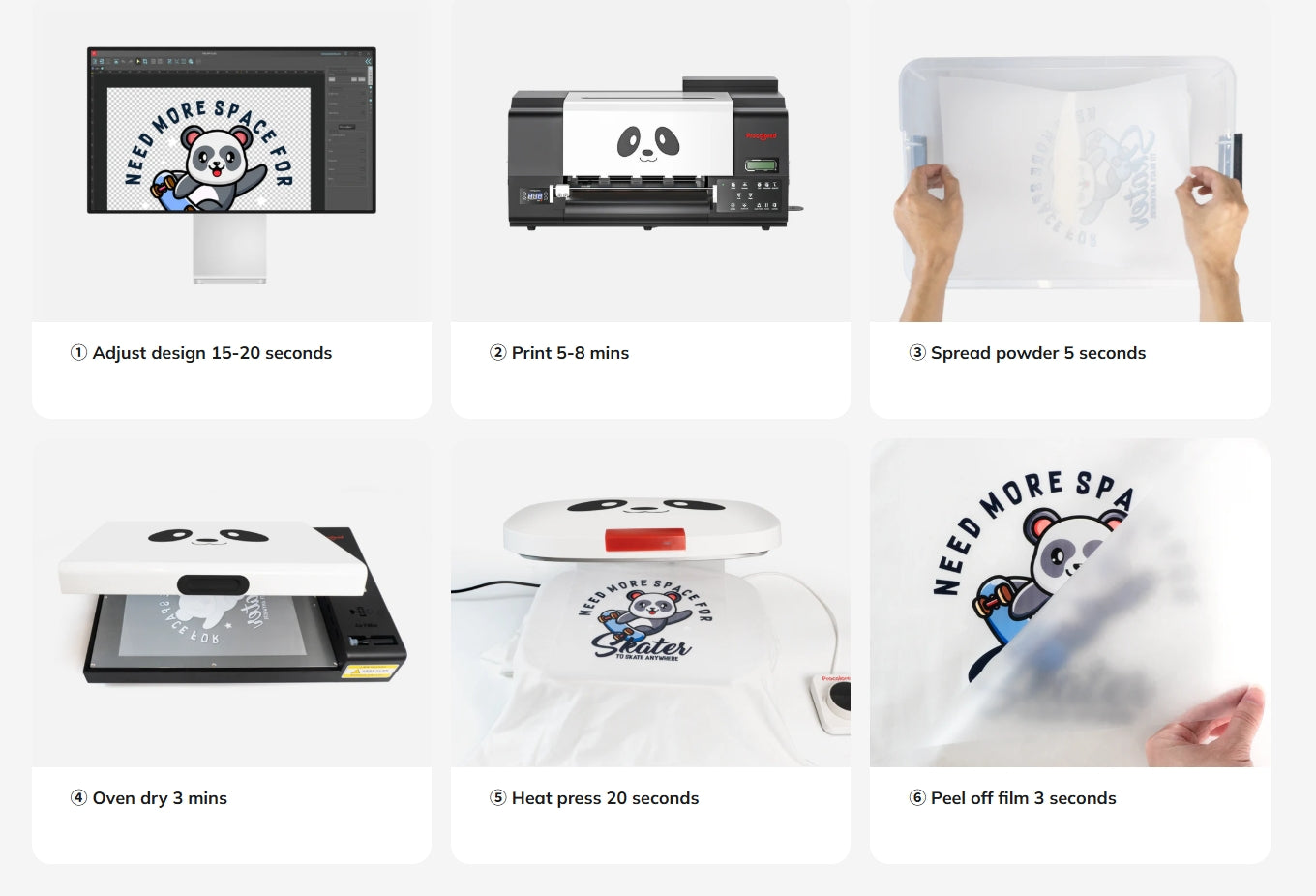

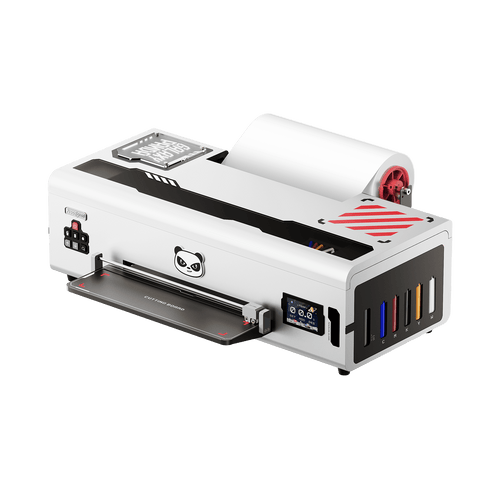

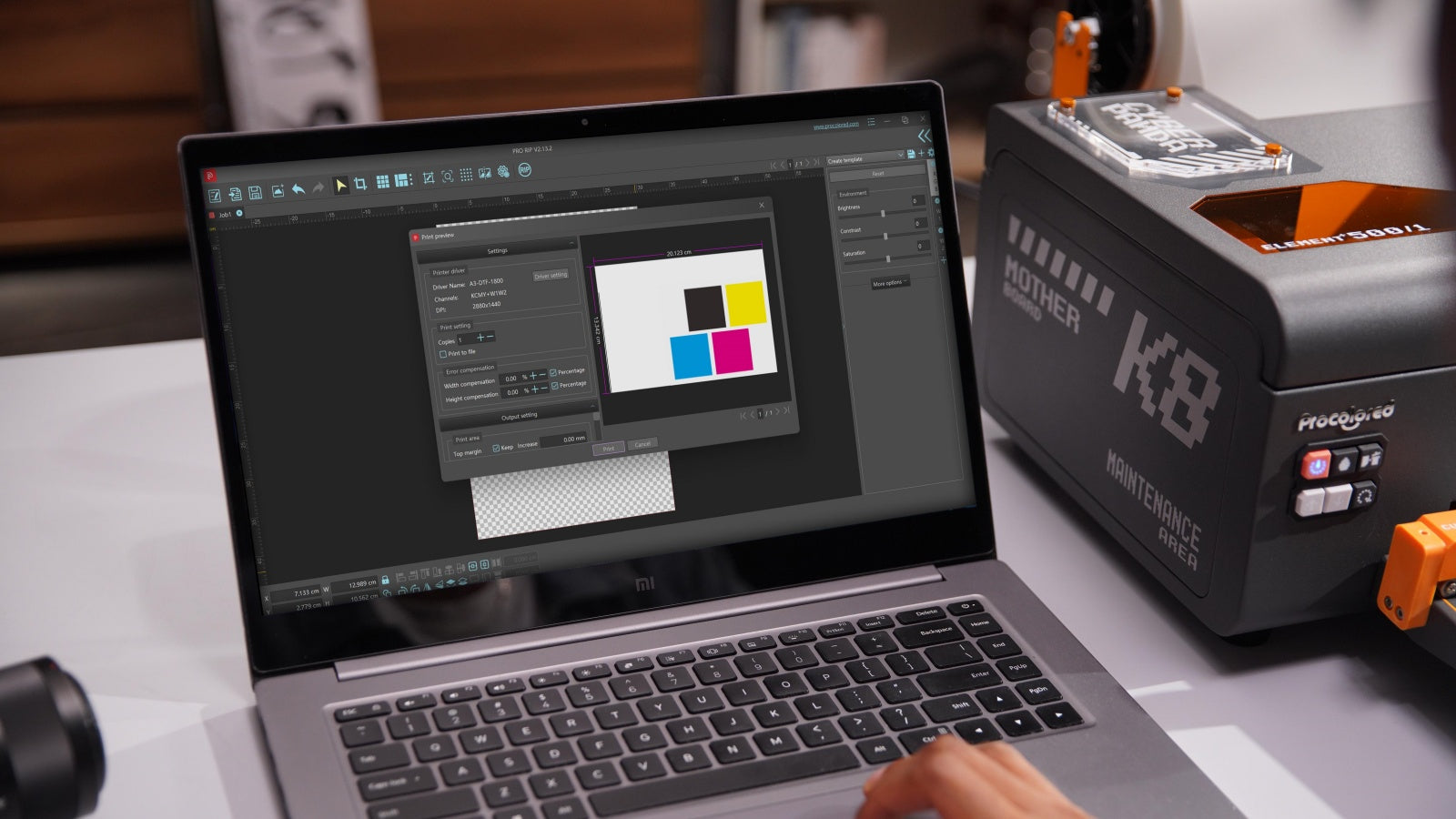

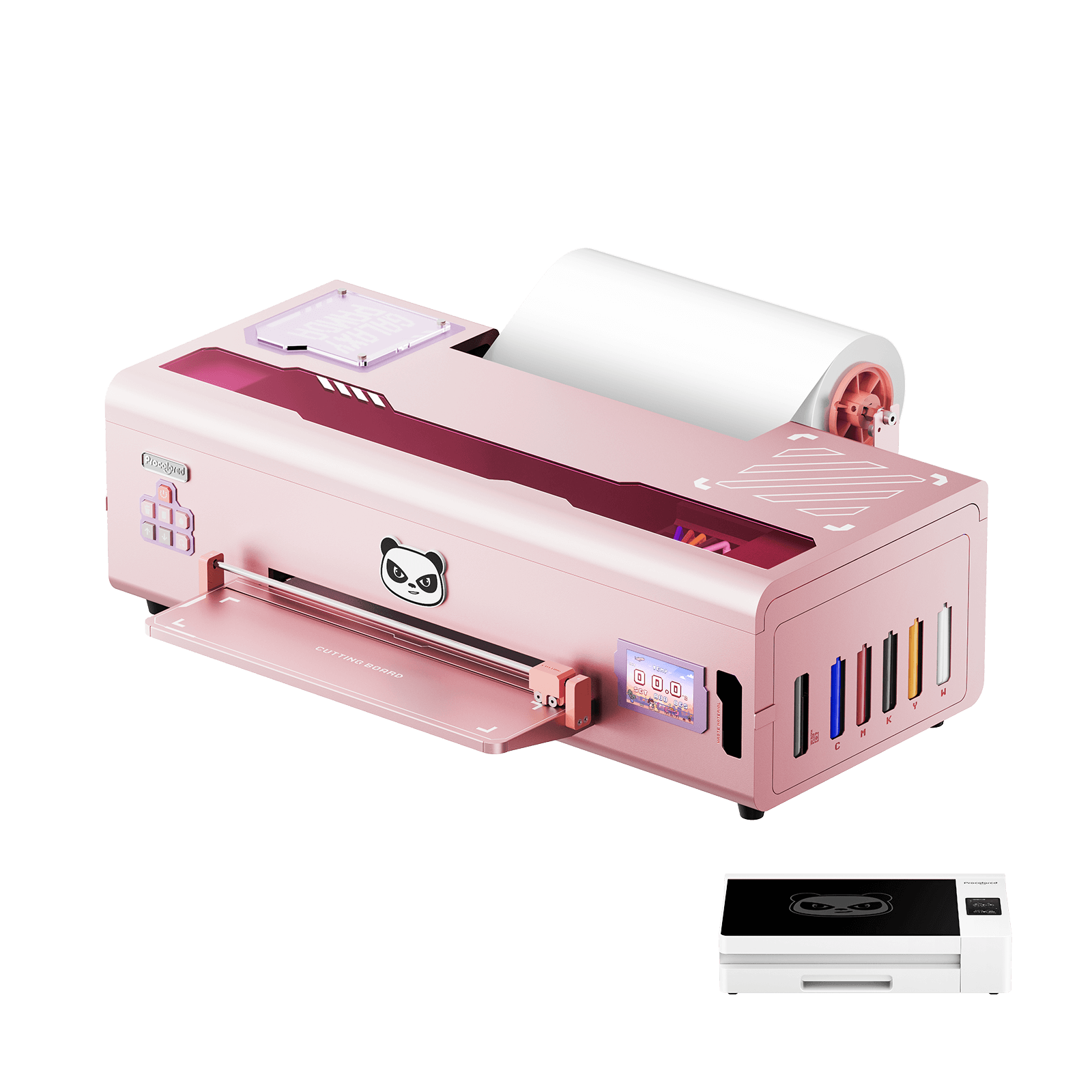

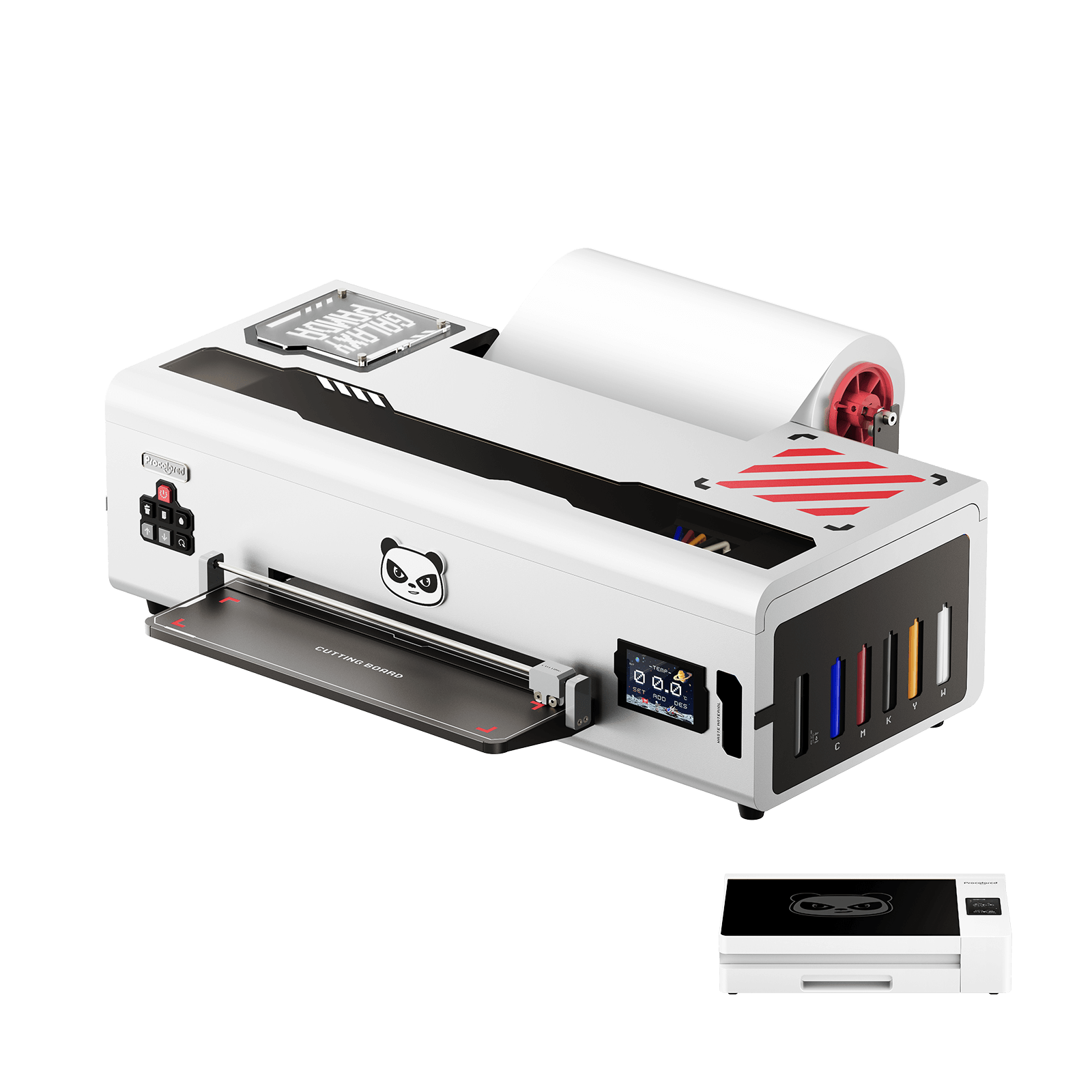

This is where tech like DTF (Direct-to-Film) or DTG (Direct-to-Garment) show their good side. Instead of treating the design like a sticker glued on the surface; the ink actually penetrates with the fabric (well, with DTG anyway), or if it does sit on top (DTF), the DTF film is damn flexible and holds up to stretches and everyday chaos. No more peeling, cracked graphics or shirts falling apart.

So honestly, next time you’re checking if a shirt will last, don’t just yawn at the tag. Ask: Will the art survive your laundry skills? With the right tech — yeah, you might finally get to say “I’ve had this shirt since high school,” and not have anyone grossed out by it.