1.Ink type

Ink is a liquid containing pigments or dyes that are used for writing or drawing. Here it refers to the ink used in inkjet printers.

There are two classification methods of ink:

(1). If classified according to color base, ink can be divided into:

Dye-based ink, which is used in sublimation printers

Pigment-based ink, which is used in DTF printers

(2). If classified according to the solvent, it is divided into:

Water-based ink - water and water-soluble solvents are used as the main components of the dissolved color base.

Oil-based ink——Using a non-water-soluble solvent as the main component of dissolving the color base.

For example, some pigment inks may be water-based inks or oil-based inks. However, in terms of their own nature and the requirements of the printer, water-based ink and oil-based ink are absolutely not allowed to be mixed.

2.The difference between DTF ink and sublimation ink

(1). Different types of ink

DTF ink belongs to pigment ink, the colorant is pigment, and the pigment has no affinity for all coloring objects, mainly relying on the resin, adhesive, etc. in the ink to combine with the coloring object.

Sublimation ink belongs to dye ink, the colorant is dispersed dye, the dye has an affinity for textile dyeing, and can be adsorbed by fiber molecules, react, and fix together.

(2). Different printing media

DTF ink also called film transfer printing ink, is used to print on a special PET film, and then transfer it to the fabric with the PET film as a medium. The principle is to fix the ink dots through the coating on the special PET film. If there is no special coating on the PET film, the paint ink will not be fixed when printed on it, and the picture will melt and cannot form a complete image. Sublimation inks are used in a similar way, it's medium is sublimation paper. Sublimation paper also has a special coating for absorbing ink, but the coating of Sublimation paper is different from the PET film.

(3). The heat transfer temperature is different

The heat transfer process of DTF ink is at a temperature of 150 degrees Celsius for about 15 seconds, while the heat transfer process of Sublimation ink is at a temperature of 200 degrees Celsius for about 30 seconds. This is because the types of colorants are different, and the dispersed dyes in the Sublimation ink can only react and develop color completely at a temperature of 200 degrees Celsius. The DTF ink does not need such a high temperature and time to fully develop color.

(4). Different media adaptability

According to the above-mentioned differences in the color development process, we can clearly judge that the media adaptability of DTF ink must be wider than the sublimation ink, especially on cotton cloth that cannot withstand such high temperatures. The color development temperature of sublimation ink is 200 degrees Celsius. Under this temperature, many materials or fabrics will be deformed or yellowed, while the color development temperature of DTF ink only needs to be 150 degrees Celsius, which can ensure that it can be used in many media. In terms of media adaptability, DTF ink has an obvious advantage. This is also one of the reasons why many people think that DTF technology has a very broad prospect.

3.Ink knowledge

Ink is slightly corrosive, avoid contact with skin and eyes, and clean it in time to prevent damage to parts. Different brands of ink cannot be mixed because of different composition, different software curves, uncertain effect of white ink, whether the nozzle is blocked, etc.

Composition of ink

|

Components |

Content |

Principal functions |

|

Solvents |

50 – 75% |

Volatile organic products used to solubilise the polymers. Principal families: alcohols, esters, ketones, glycols and water. |

|

Binder |

15 – 30% |

Constituents of the binder (solvent + polymer) that largely determines the adhesion on substrates, the gloss and the mechanical, physical and chemical properties of the ink. |

|

Organic colorants |

8 – 20% |

Pigments chosen as a function of the binder and the fastnesses required by the application. Constituents that enable intense and very transparent inks to be obtained. |

|

Additives |

3 – 5% |

Products that confer specific properties to the ink such as rheology, adhesion, rub and scratch resistance, anti-foaming effect, etc |

4.About white ink

White ink is not only the background color of other colors but sometimes it is also used to directly display white patterns, so the effect of white ink is particularly critical. However, due to the characteristics of white ink, it is more prone to sedimentation than other color inks. We recommend that you use our white ink. Shake the white ink bottle before starting to print every day to ensure the activity of the ink. And use F12 to clean the print head, and at the same time, it can ensure the stable output of the white ink path.

White ink circulation: It means that our printers add a small circulation pump motor between the white ink bottle and the ink damper, which can extract the white ink to increase its activity and uniformity.

White ink stirring: there is a stirrer in the white ink bottle, and it will automatically stir the white ink every 30 minutes after starting up to prevent excessive white ink precipitation.

5.Corrosivity of ink, precautions for maintenance and operation

(1) Try to keep the printer turned on every day (use the RIP software to clean the printhead before printing your image).

(2) If the printer is not used for more than three days, you need to pay attention to the printhead, it may get clogged.

(3) Ink and other liquid must not enter the print head cable, or the printhead may get burned.

(4) There should be no ink liquid residue on the surface of the nozzle, and it should be cleaned at any time.

(5) Clean the waste ink pump, wipe the grating strips with an alcohol-free dust-free cloth, wipe the guide rails of the ink car, and add lubricating oil.

(6) After the printer is finished working every day, clean the residual ink or liquid that can be seen.

(7) According to the workload of printing, regularly check the ink and cooling water and increase.

(8) Do not expose the printer to direct sunlight.

6.Ink’s shelf life, storage, and use environment

(1) Do not open the package when the cartridge is not in use.

(2) After unpacking, please use it immediately and use it up as soon as possible, preferably within three months after opening. The best shelf life of ink in unopened containers is six months.

(3) Solvent-based ink cartridges contain flammable liquids, please keep them away from fire sources, and they are corrosive and irritating to a certain extent, please do not inhale them, and pay attention to safety. Store in a cool/dry/ventilated place out of direct sunlight.

7.What kind of ink is easy to clog the nozzle

(1) Poor quality ink

(2) expired ink

(3) Mixed use of different types of ink

8.The relationship between the ink and the curve(ICC profile) in the software

(1) The ink curve is an ink output scheme that the printer that uses a certain ink ratio to print on a certain medium, and each printer has a default ink output scheme.

(2) The commonly mentioned CMYK color of the ink is the 4-color color of the printing standard. For high-quality ink, each color should be close to the theoretically specified printing color. However, there are some differences in the color of the inks in the actual market. This difference is caused by differences in ink raw materials, production technology, and strict compliance with printing color standards.

(3) The curve of a certain ink is only the ink output scheme given for the ink to be used for a certain printer to print on a certain medium. In theory, if any factor of ink, printer or medium changes, then For the same ink output scheme, the output results will be different, and the difference may be very large or very small. For personalized printing of diversity, using a certain off-the-shelf ink curve may not necessarily have the best print output results for each of your specific print job outputs. For each specific printing, a new ink output scheme, that is, a new ink curve needs to be given. In fact, when there is no specific curve given for a specific printing job, the existing ink curve is not very meaningful to the user. At this time, the ink curve can be used as a reference.

(4) The printer software (RIP) has a powerful color adjustment function, and the required output quality can be obtained through the adjustment function.

- There are three core factors related to inkjet printing output quality: the printer itself, ink quality, and the software processing system. The perfect combination of the three can give the best color.

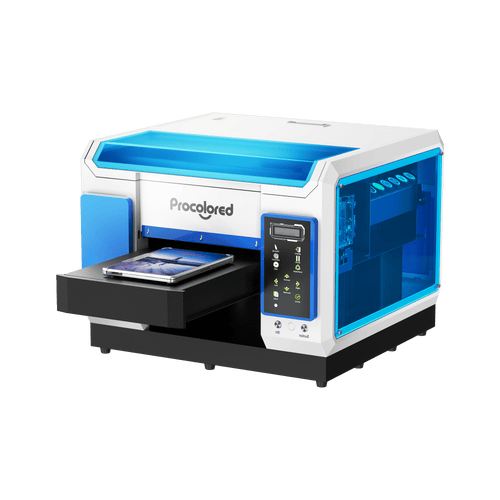

9.Why Use Procolored INK

Procolored ink has been tested for a long time, it is not easy to clog the printhead, and the quality is stable, which is the best fit for our printer

The ink manufacturer customizes it according to the color curve of our printer, and the printing effect will be better.