Fluorescent Transfer Film

The origins of Halloween goes back to an ancient Celtic festival named Samhain, where it was believed that the boundary between the living and the dead was blurred on this particular day. On Halloween, people often decorate their dressing with spooky patterns. T-shirts will be popular coming with decorative items like artificial cobwebs, skeletons, tombstones, inflatable characters, witches' hats and more. It is a time for people to showcase their creativity. If you are doing a T-shirt business, you would like explore some creative designs for DTF printing on shirts.

In this article, we dive into a new world of luminous DTF transfer film and check out every details about the usage. Imagine a world where your printed designs glow when you stand in the dark places.

On the printable side of the heat transfer film, there is a layer of fluorescent coating in light green. Patterns are printed on the coating and when the print is transfer onto a shirt, the coating comes along with the print and sit on the surface of the patterns. The fluorescent matters of the coating can be activated by UV rays from UV lights or sunshine. The beauty of this type of T-shirt print lies not only in their daytime appearance but in their nighttime appeal. As sunlight graces the printed design during the day, the fluorescent layer silently absorbs the energy. Once the shirt is put into darkness, the magic unfold - each detail of the design radiates a gentle, mesmerizing glow. It is funny to wear a T-shirt with weak glow effect at nighttime.

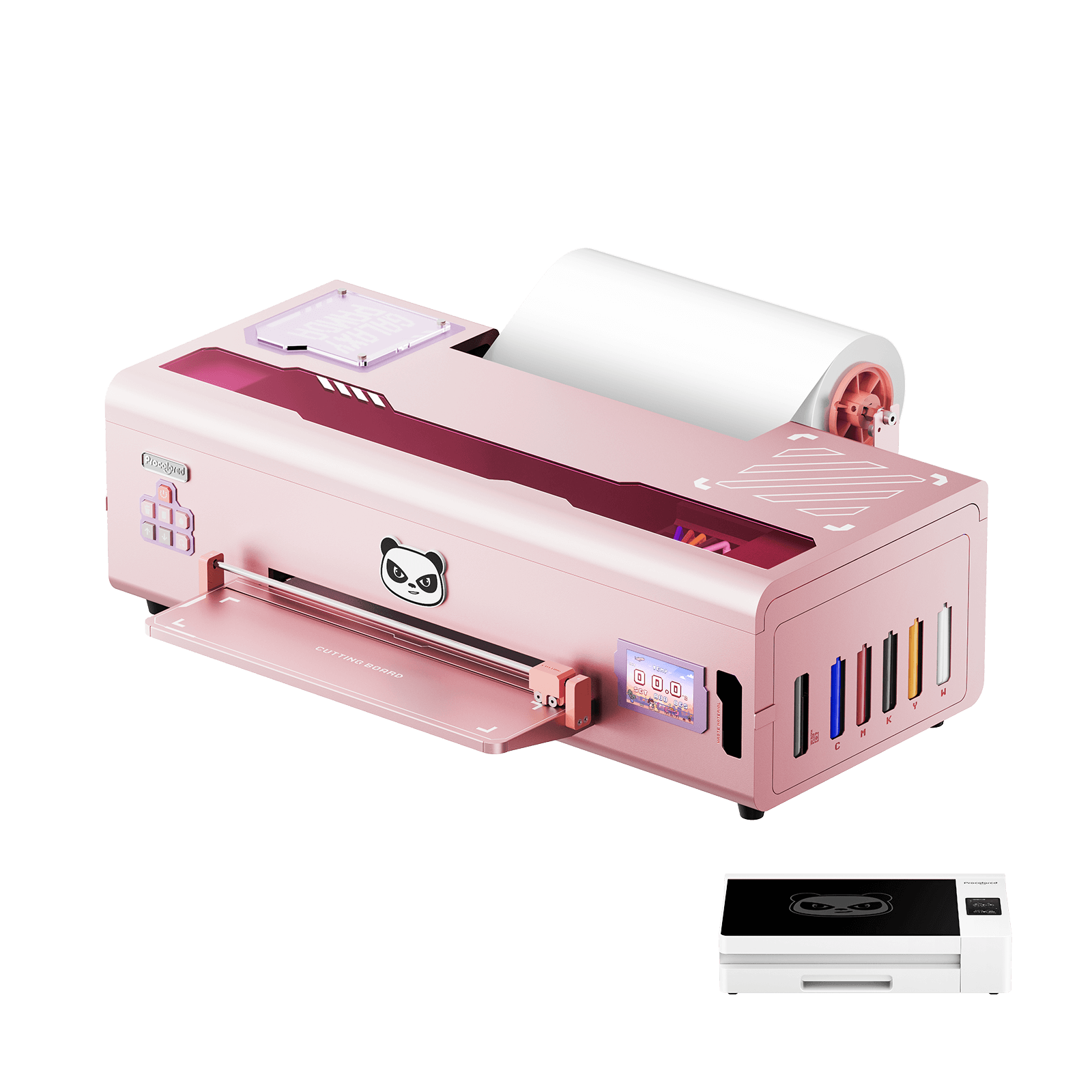

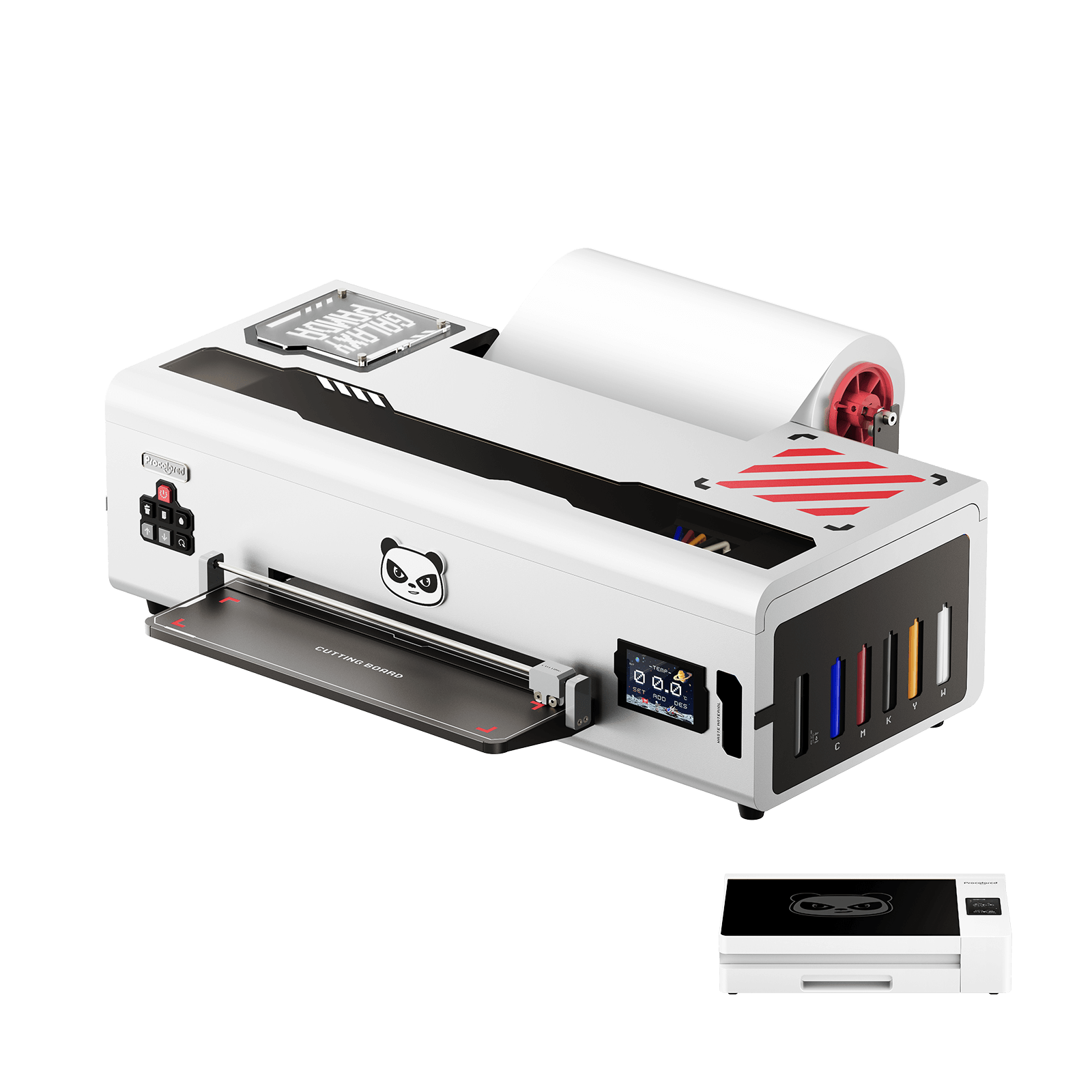

Print on Film Sheet

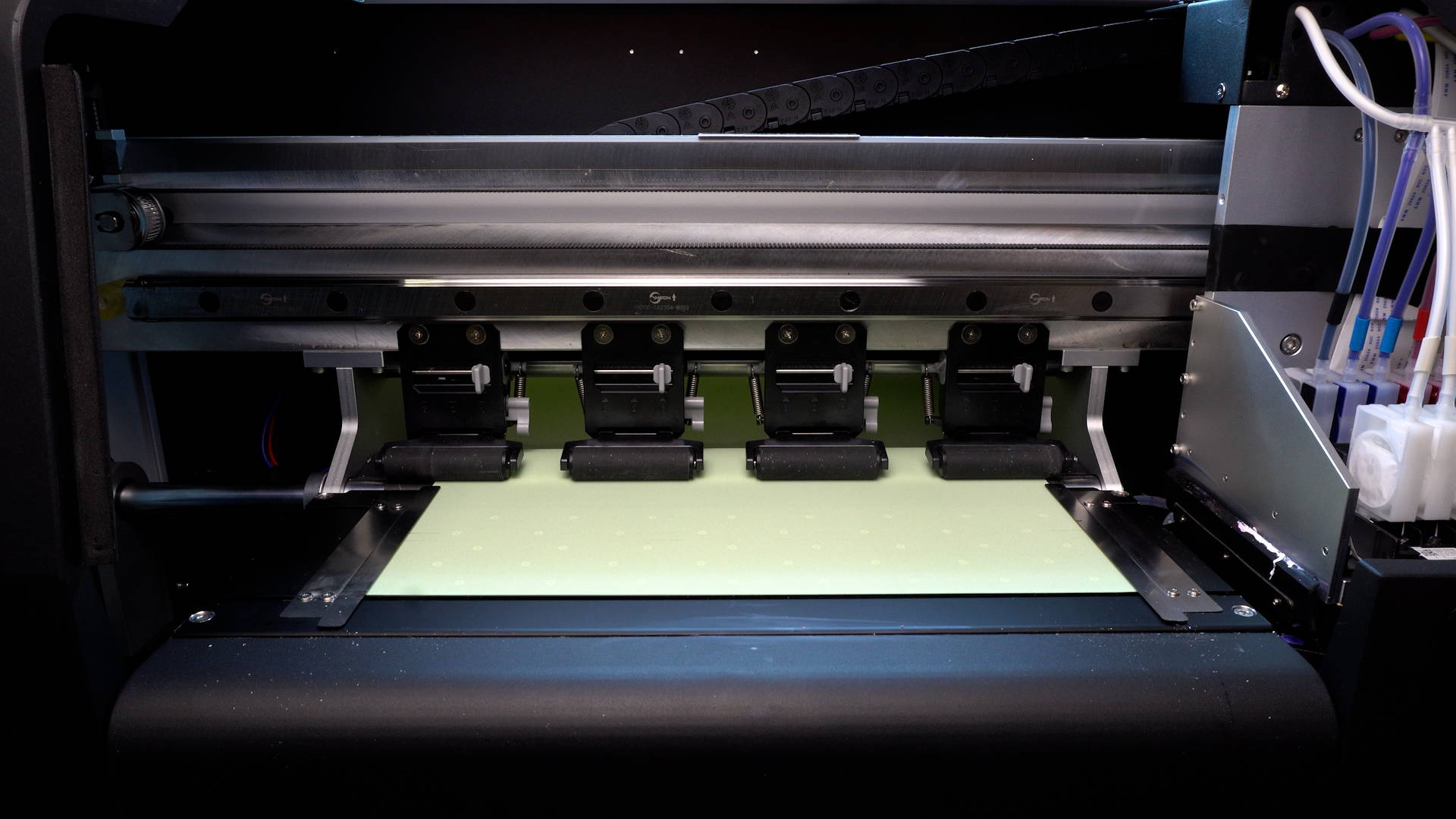

Here is the procedure of producing T-shirt with fluorescent design. The first step is to create a fluorescent print. This dual-head DTF printer adopts YMCK color inks and a white ink to print colorful and vivid patterns. The patterns are print on the fluorescent DTF transfer film. After the printing is finished, cover a layer of adhesive powder all over the print which is still in wet. Curing the adhesive powder in a heating oven. Set the temperature at 125 degrees Celsius and the countdown timer to 130 seconds. The curing time is flexible, if the print is too wet, it need longer time to dry up entirely. In the oven, adhesive powder is melting down, inks are drying up and the fluorescent coating is embedding onto the print. After the curing is finished, wait for the transfer film cooling down naturally.

Transfer onto T-shirt

The next step is to transfer the print onto the shirt. Set the temperature of heat press at 135 degrees Celsius and timer to 15 seconds. It takes no much time for the machine to transfer the designs onto fabric of the shirt through a process of heat and pressure. The adhesive layer will be melt down the second time and stick onto the T-shirt fabric. Peel off the transfer film when it is cooled down. Now the creations on your T-shirts possess the magical ability to glow at night. The fluorescent material on the surface of the T-shirt print can absorb the energy from lights and reach at a higher energy level. It tends to return to its original state and release some energy. When you turn off the lights after shining a light on a fluorescent material, it continues to glow because it's slowly releasing the stored energy in the form of visible light.

How Does It Work?

The glow can not go through the night if the print stop absorbing energy from lights, but any light in the environment can provide some energy to the print. When you walk from a bright environment into darkness, there will be a mesmerizing glow on your shirt which will last for a while. It is a hidden surprise that the garments on your body become a storytelling canvas and capture attentions where you can showcase some interesting words, patterns or logos.

T-shirt designers often use fluorescent coatings to add creative and artistic elements to their designs. Dressings with fluorescent designs are suitable for events like parties, themed gatherings, Halloween celebrations. The designs make you look cool where everyone is dressing up. Your outfit becomes a colorful and attention-grabbing highlight. So, step into the world of T-shirt transfer film with glow effect and experience the magic of fluorescent DTF printing like never before. Let your designs not only reflect your style but also light up your celebrating nights.

Future Development

As materials science and production process develops, we could see the future of even more efficient and vibrant fluorescent coatings. People want their t-shirt designs come with brighter and longer-lasting glow effects. And it may integrate with smart clothes that involve sensors or LEDs. They can be used for educational purposes, showcasing some scientific concepts or laboratory system in a visual way. We could also see a future that fluorescent elements come into the design of traditional and cultural clothing and produce a modernized fashion.