Before you decide your printing partner, make sure you answer these few significant questions first.

👕 What Fabric Are You Printing On?

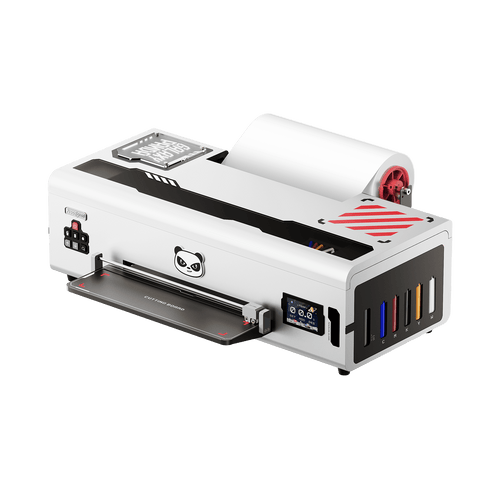

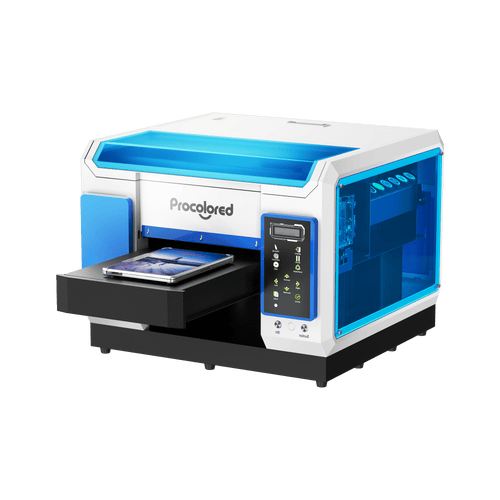

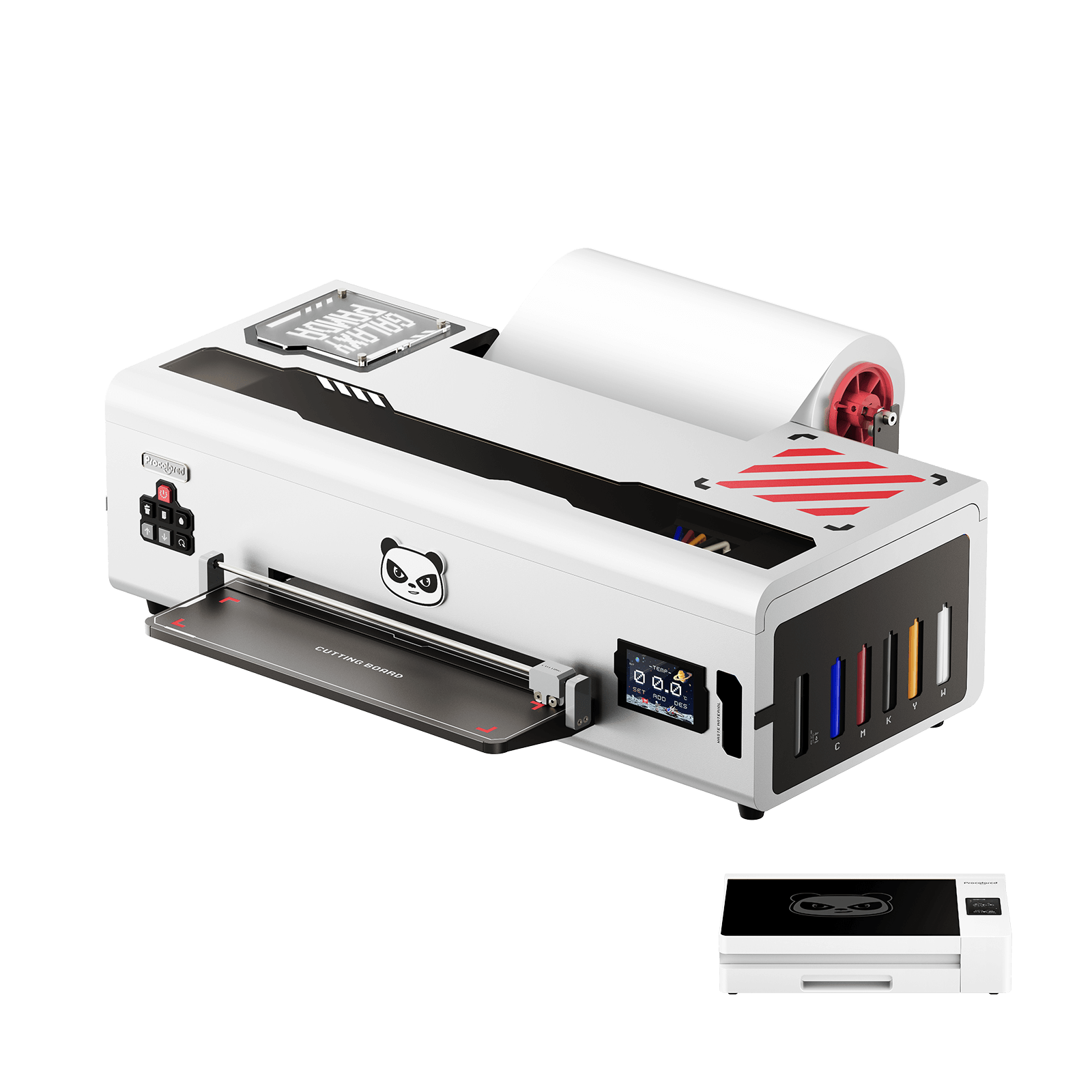

DTG loves 100% cotton and it is where DTG works remarkably. So, if you plan on sticking to soft cotton tees and pillows, DTG is your go-to-choice. However, if you plan on exploring polyester, nylon, or even some performance wear, then best DTF printer is the more adaptable option.

📦 How Many Orders Are You Handling?

If You’re dealing in small batches, one offs or personalized prints, then DTG is great for you. Especially if you’re printing on demand, it makes things efficient. The contrary is true for bulk printing though. If you would like to prepare a batch of designs ahead of time, then DTF makes those processes easy and quick.

💰 What’s Your Budget And Long Term Vision?

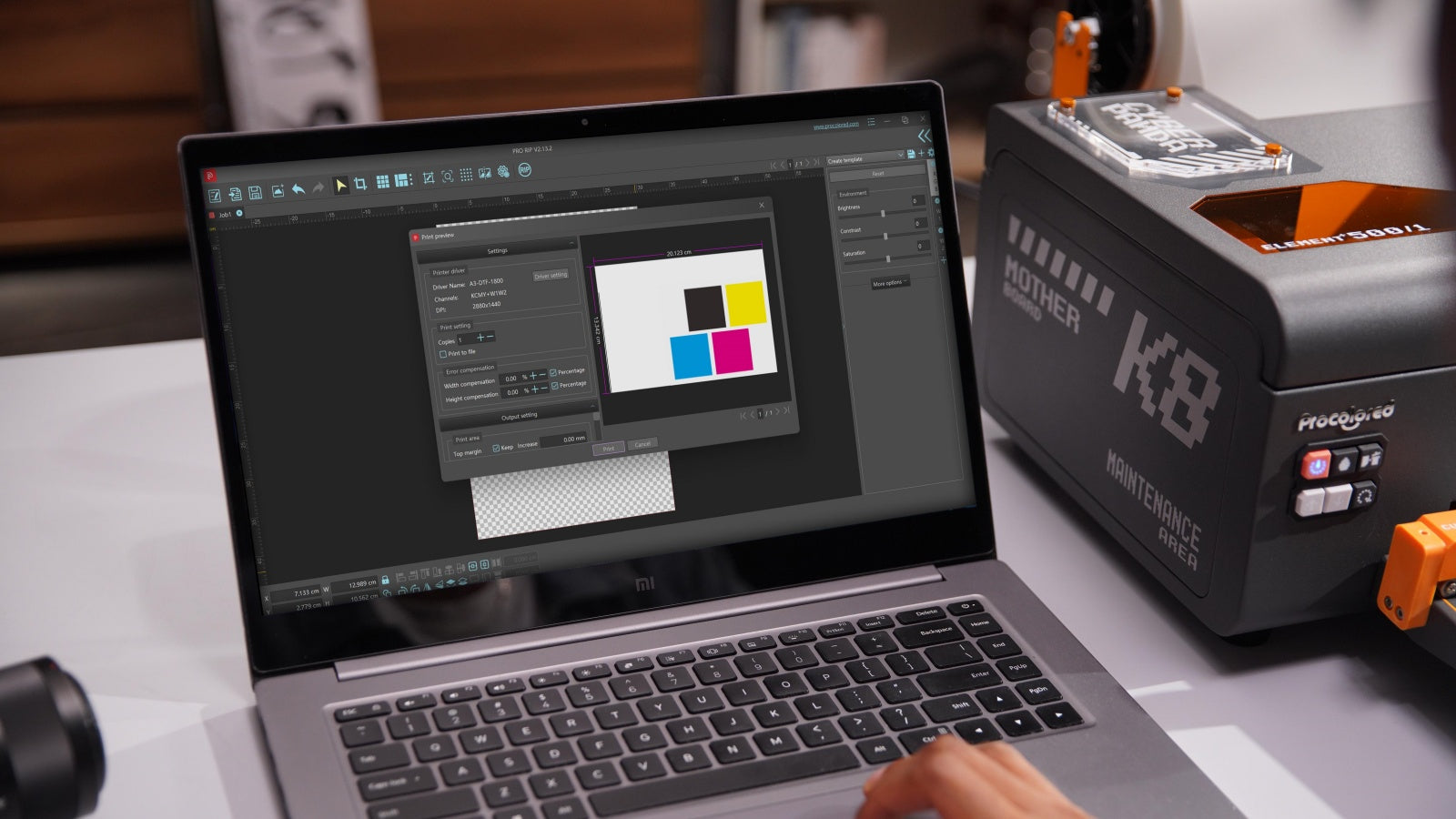

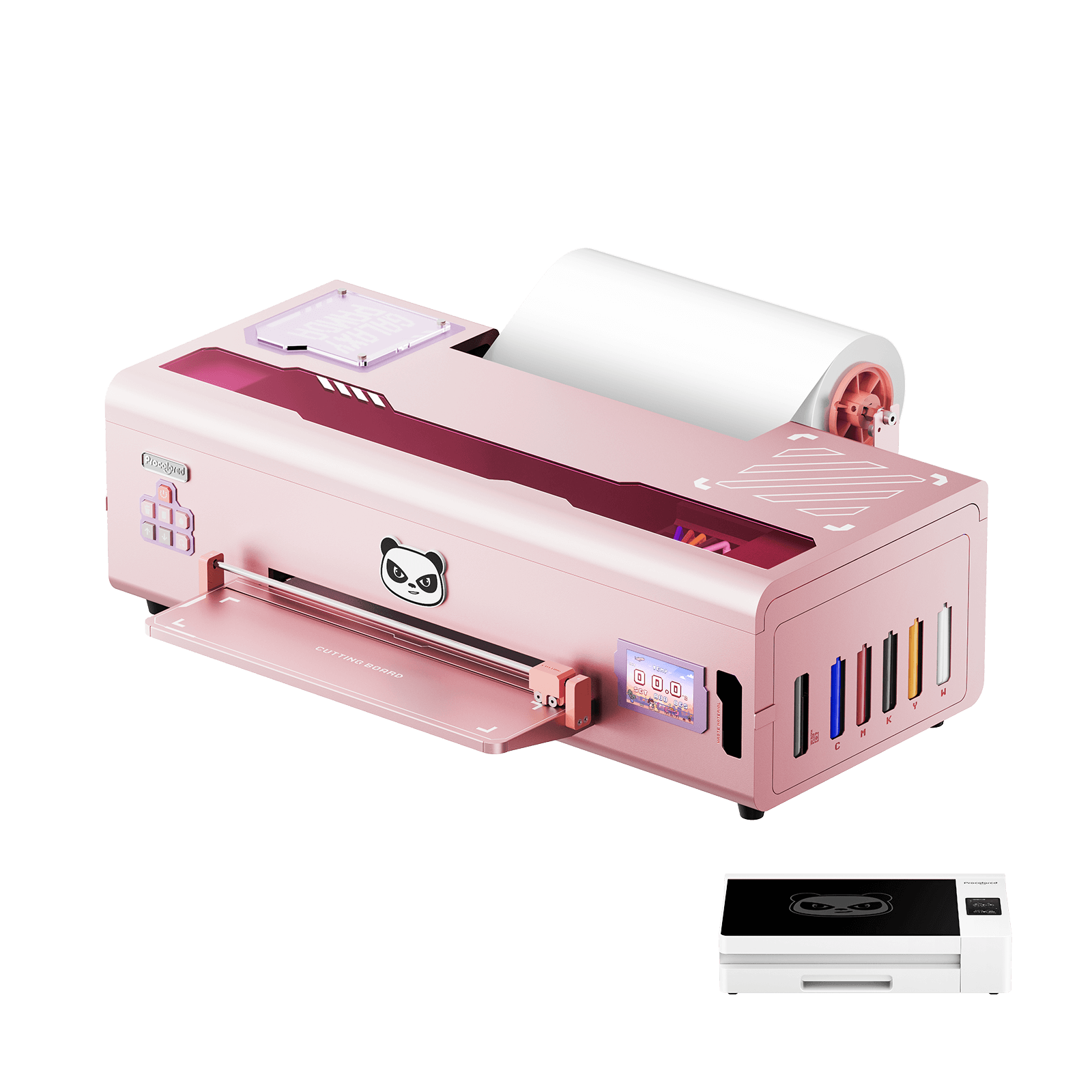

If you want to go with DTG, it is an expensive investment upfront–not just in printing but in maintenance and space. DTF setups tend to be more affordable and compact which is always a plus for those just starting out.

🎯 How Much Detail And Precision Of The Print Is Necessary?

DTG has the ability to achieve more photographic accuracy, and intricate detailing, particularly on lighter materials. Though DTF prints are vivid and long-lasting, they might not capture some of the ultra-fine details achievable with DTG.