Time to catch the info that truly means business

As traditional printing methods are being less and less considered, where will printing industry go?

Keep scrolling and let’s find that out.

PASSAGE SUMMARY

1. From traditional printing to digital

1.1 what is digital printing

Digital printing sounds quite familiar to us now, since we’ve made friends with inkjet or laser printers at home and in office for quite a long time. Yet digital printing includes far more than that.

Digital printing was first invented as inkjet printing and used for industrial applications only during 1950s-1960s. With popularization of computers, inkjet printing developed rapidly in 1980s and started to serve for home and office users, greatly heightened the working efficiency.

Since then, not only inkjet printing, but also other digital printing methods like laser, heat transfer printing were invented and have been improved, gradually changing the manufacturing industry and becoming more and more popular.

Take photography printing for example, people used to develop photos via darkroom printing during the era of film cameras. And as digital cameras and mobile phones started to be the dominance of customer electronics, the more common printing ways changed into inkjet and laser printing.

Digital printing has influenced book printing industry too. Though offset lithography printing remains the most frequently used book printing method, more and more publishers and self-publishers turned to digital printing as a way to meet their printing needs.

Not to mention apparel digital printing. Screen printing has traditionally been the most popular method for apparel decorating, particularly for large-scale production runs. However, in recent years, with more and more different digital printings like DTG (direct to garment), sublimation, and DTF (direct to film) printing coming out, apparel decorating industry has been faced with big revolutions.

1.2 why digital printing excels

To explain why digital printing excels, we should first figure out why traditional printings gradually lost their shares of the market.

Take screen printing, one traditional apparel printing method for instance, screen printing is more suitable for large-scale production runs since A) it’s a more expensive investment being cost-efficient only to large business holders B) it’s capable of processing large format printing, which means the printing session can be processed on multiple cutting pieces or clothes simultaneously. But that always works perfectly only when it comes to solid color printing.

Applying screen printing method to do multiple colors printing would be a long and tedious story (gradient printing excluded). Multiple colors printing needs multiple screens (or stencils) since each screen can only support ink in one color. Whenever a color printing is finished onto the fabric, time must be taken to dry it first before printing the next color.

Digital printing achieves printings in more convenient and friendly ways, take inkjet printing for example:

inkjet printing uses nozzles to spread out inks in different colors at the same time

users finally free themselves from endless laboring - generally inkjet printing co-works with computer software, there’s no need to wash screens or squeegee ink manually as screen printing requires, or precisely formulate chemical solutions as darkroom printing requires

there are more and more new printers developed in lightweight sizes and favorable prices, which is totally friendly to industry new beginners

inkjet printing is suitable for a wide range of fabric substrates

2. Print-on-demand is in demand

2.1 how does print-on-demand differ

Print-on-demand is a concept opposite to mass manufacturing. Two major differences between them:

A) The order quantity of mass manufacturing tends to be large, and normally it needs big or numerous machines to achieve quick and big output in a short time; while print-on-demand orders tend to be of smaller quantities requested by individual customers instead of big trading companies, small businesses holders are also capable of handling these orders as long as they've got the fitting machines.

B) Mass manufacturing produces uniform products to save development cost; while print-on-demand products emphasizes personalization and customization.

2.2 why print-on-demand is the new trend

Business can only be achieved when it involves potential consumers and ambitious producers, and that’s the main reason why print-on-demand is the new trend:

what potential consumers want :

A) Tailored products - abundant ideas swarm into consumers’ minds through internet every day and now they’re asking for more and more tailored products to meet different needs. They might ask for curtains in specific dimension, demand for cups with specific colors, or search for t-shirt printing online to make team uniforms for the coming activity. They need things with design and pattern that are far more than “just okay”.

B) Uniqueness through customization - some other consumers aim to reflect their tastes or preferences via customized products. They might be interested in printing their favorite singers on things they buy or using their own photography works to make a new year’s calendar. Print-on-demand allows them to enjoy this uniqueness without paying too much for the minimum order quantity (MOQ).

what potential consumers want :

A) Tailored products-abundant ideas swarm into consumers’ minds through internet every day and now they’re asking for more and more tailored products to meet different needs. They might ask for curtains in specific dimension, demand for cups with specific colors, or search for t-shirt printing online to make team uniforms for the coming activity. They need things with design and pattern that are far more than “just okay”.

B) Uniqueness through customization-some other consumers chase for customized products to reflect their tastes or preferences. They might be interested in printing their favorite singers on things they buy or using their own photography works to make a new year’s calendar. Print-on-demand allows them to enjoy this uniqueness without paying too much for the minimum order quantity (MOQ) .

what ambitious producers want :

A) Higher unit price - different from ordinary mass production orders, customized products need more charges on designing, calibrating or adapting, thus raising the unit price of the products.

B) Mutual connection - personalized products and services create a sense of connection between consumers and producers. Being provided with products marking personal style and feature, consumers tend to rely on the producer more and choose it over other competitors for the next purchasing.

3. Universal goal - sustainability

Eco-friendly has been the main topic of global issues for years. And even in printing industry, it has been one of the new fashions and prominent selling points. There are ways to improve sustainability in printing industry and some companies have already taken them into practice.

3.1 print with low VOC content

Volatile organic compounds (VOCs) are chemicals that can evaporate into the air and contribute to air pollution. Digital printings like screen printing, heat transfer or direct-to-garment (DTG) may sometimes contain VOCs in their solvents, inks or coatings.

High levels of VOCs will not only threaten human health, causing headaches, dizziness or even respiratory problems; but also do harm to our surroundings by polluting the vegetation, water, air and exacerbate climate changing.

To alleviate the problem, some printing companies start to replace solvent-based inks with water-based or UV-curable inks; besides, they also improve the ventilation and air filtration systems to reduce VOC emissions.

3.2 reduce waste

As it’s mentioned in almost every business email, “think twice before printing” is one workable way to reduce printing waste. Many companies nowadays encourage their employees to process business through digitized forms to save ink as well as papers.

And as printer owners, reducing waste can be achieved by doing regular maintenance to the printers. Effective maintenance is helpful in preventing ink clogging issues thus reducing defective printings.

3.3 participate in recycling

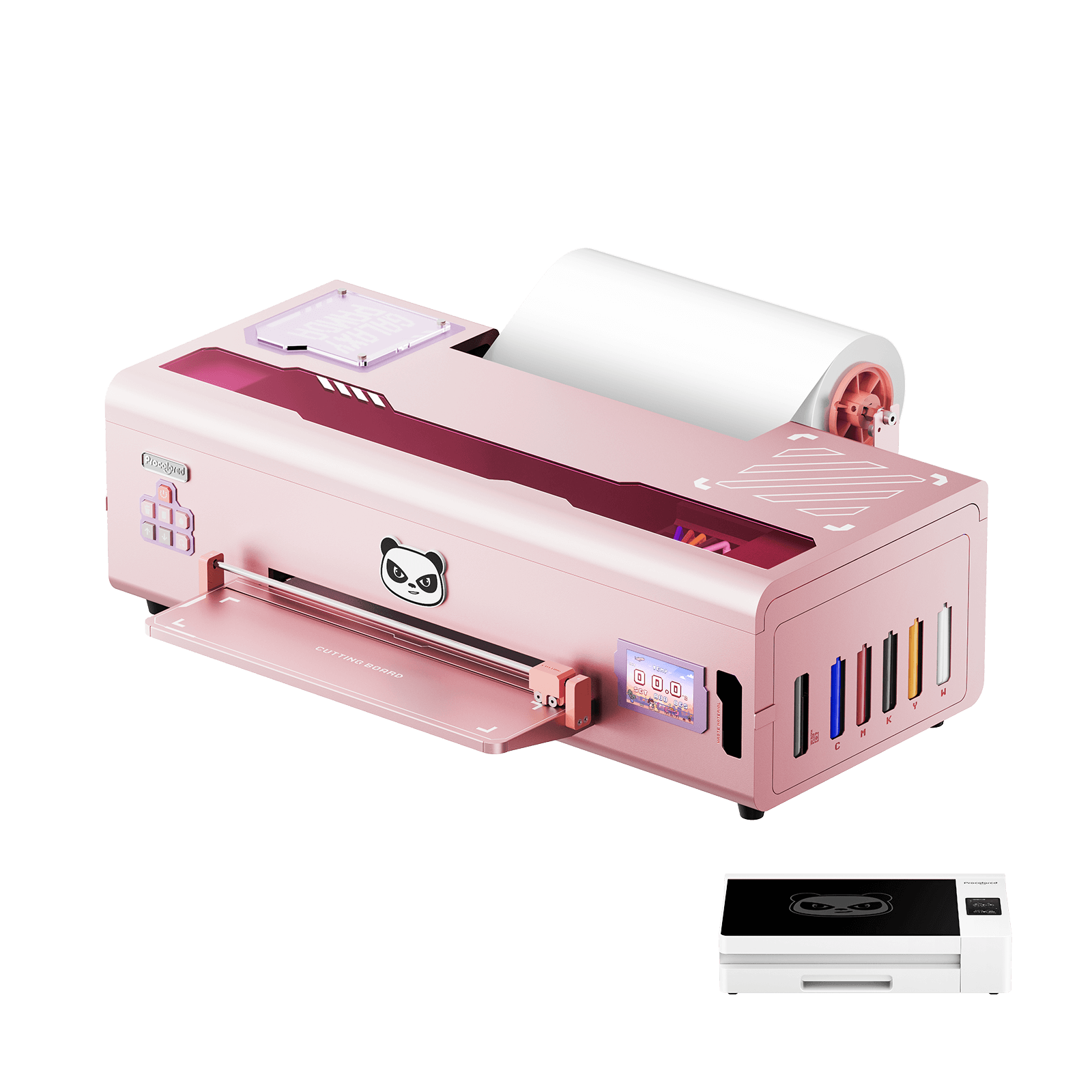

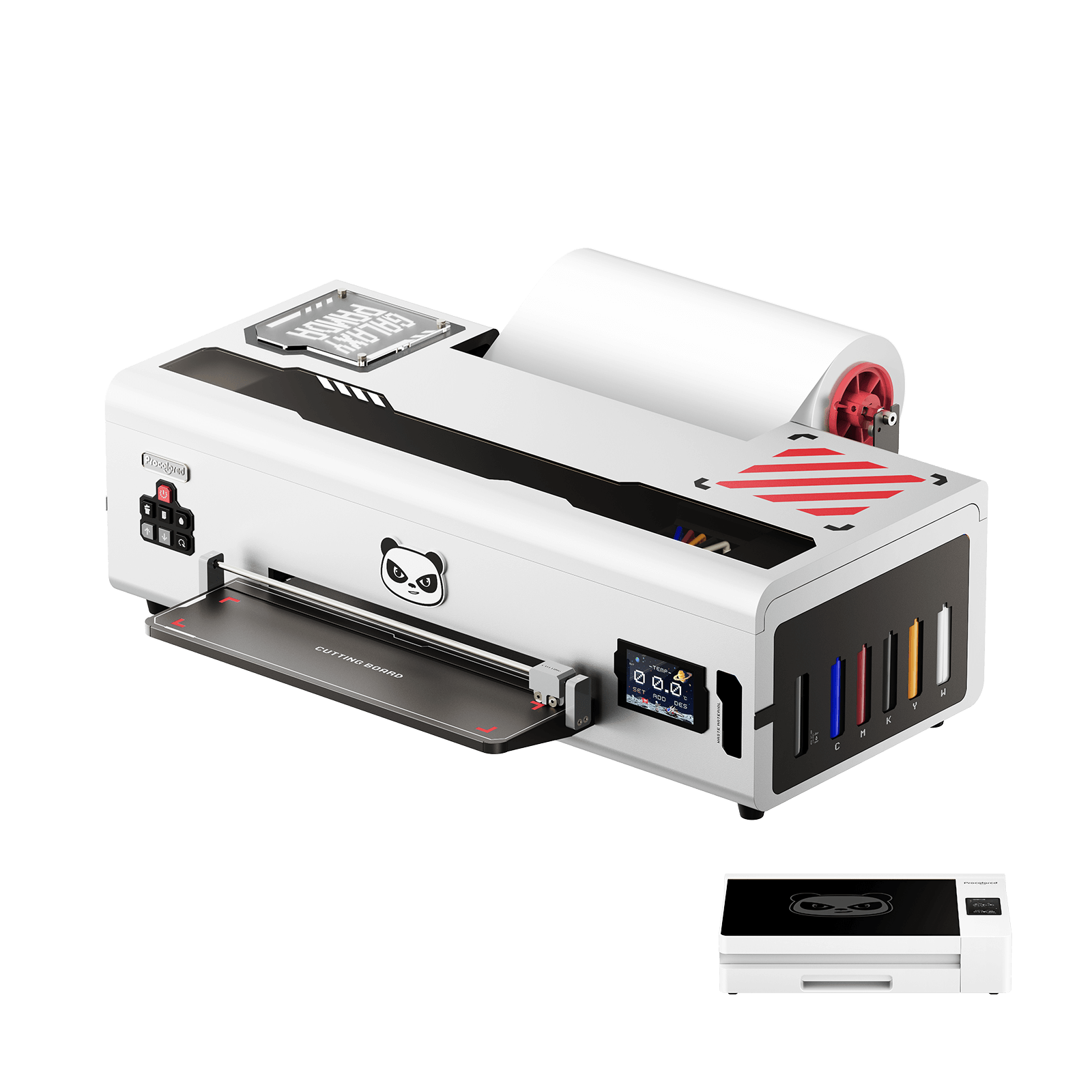

There are ways to implement recycling in printing industry. For example, some printer brands change the colorful appearances of their products into natural color, thus reducing the applying of industrial pigment which will do harm to the environment; some printer companies encourage their customers to return the empty toner cartridges by prepaying express charge for them.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!