Is anybody still keeping doing a sublimation? Please change your mind and start with DTF right away, here are some tips why I did move sublimation to DTF.

- Simpler Operation

I am going to do some short expounds on sublimation and DTF for those people who are new to the two areas.

“Sub-li-what-now?!” If you’ve ever wondered what this strange-looking word exact means — then wonder no more.

No, it isn’t an underwater warship or on-screen translations that help you understand a foreign film; it’s a high-tech printing process used mostly for print-on-demand apparel. Today we’re going to pick it apart — we’ll cover what it is, how it works, discuss the pros and cons when to use it — and when not to.

What is sublimation?

Let’s start with the broad strokes. What exactly is sublimation?

In simple terms, it’s a method of printing that transfers a design into a material or fabric using ink and heat.

In the world of apparel, it’s a game changer in that it allows whole garment prints — designs that go seam-to-seam.

The sublimation printing process

So how does sublimation work? Well, sublimation printing uses heat to essentially bring ink and fabric together as one.

First, a design is printed onto special paper. The inks that are used turn into gas when brought under heat, then combine with the fabric and permanently print onto the fabric. The effects are permanent and less prone to fading, as the ink is embedded in the fabric or substrate rather than simply laying on top like a normal print.

The process is almost like a tattoo, but instead of for your skin, it’s for your chosen product. The heat opens up the pores of the fabric, then with the applied pressure the ink cools and returns to a solid form.

The result is a permanent, full-colour image that won’t crack, peel or wash away from the substrate. The process allows the ink to go from a solid to a gas without turning to liquid, a bit like dry ice. The conversion is initiated by heat and controlled by pressure.

This quick and effective digital print method is growing in popularity for smaller batch orders and those designs that rely on the details. Sublimation printing is also known as ‘all over printing’ as it allows you to choose a design that can go from seam to seam.

②. DTF: What is DTF Printing?

I’m sure you've heard of DTF printing before but may not be familiar with how it works. Or perhaps you got it confused with DTG printing.

DTF stands for Direct To Film. This technique involves printing your design directly onto a film and then transferring it to a T-shirt made of cotton, polyester, or their blends, regardless of their color, as it can work with white ink.

How to do print DTF transfers?

A great advantage of this technique is that the white ink layer is printed simultaneously with the color ink. This feature makes it a very simple alternative compared to other methods such as white toner.

If you’re working with DTF, you should know that the valid formats for printing your designs are the following: eps, ps, pdf, bmp, tiff, jpg, png, and psd.

We have prepared the following video to show you step-by-step how to make DTF transfers at home on a dark cotton t-shirt:https://www.youtube.com/watch?v=NalVl2KwS-4

What do I need to print DTF transfers?

Now that you know about DTF printing and what you can achieve with it, you may be wondering what equipment you need and how much of an investment it will be for your business.

What you’ll need

Let’s start by listing the equipment and machinery you’ll need:

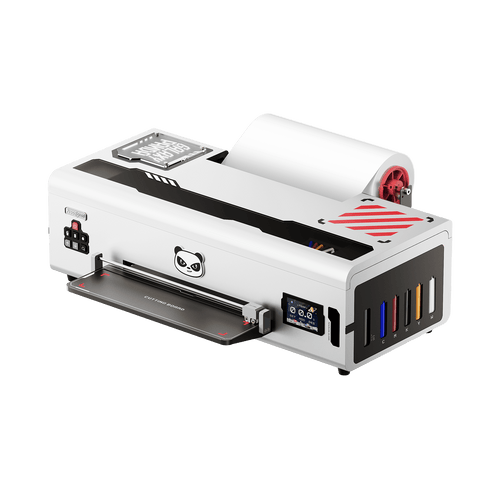

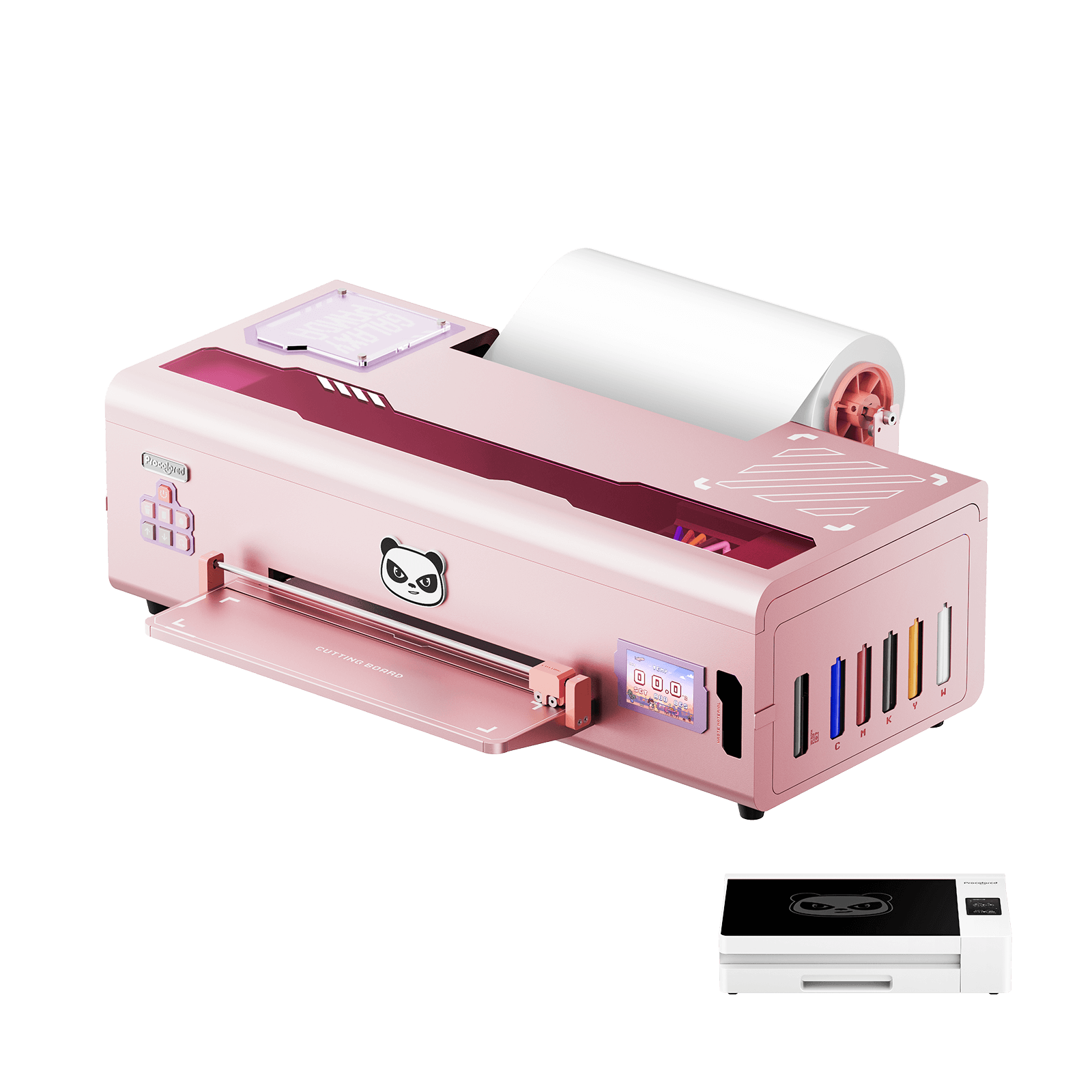

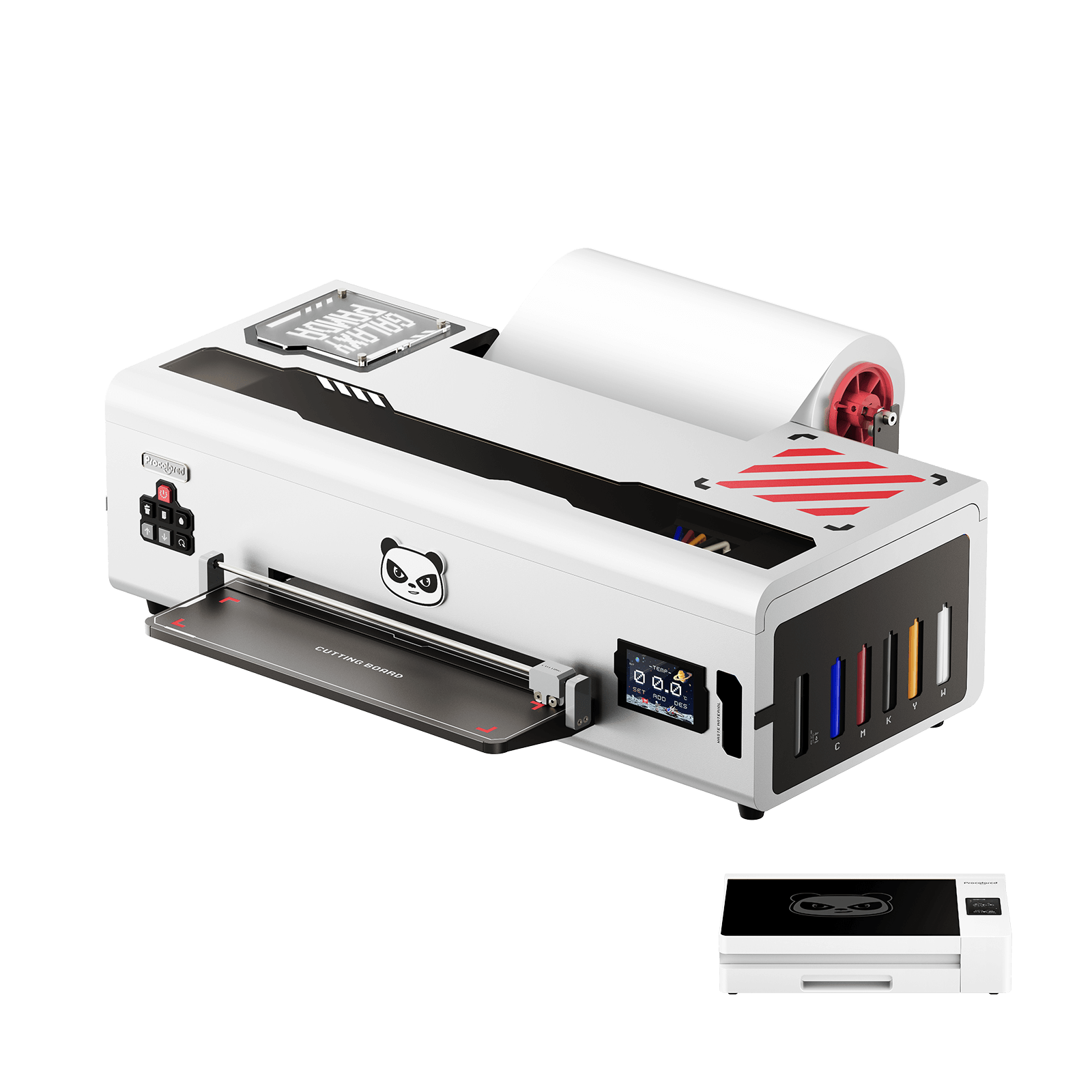

- Inkjet printer modified for DTF printing with 6 ink channelsCMYK+White:At Procolored, we have the ultimate DTF printers with all the necessary hardware modifications.

- Special inks for DTF printing:these very elastic inkjet inks prevent the print from cracking when stretching the garment after printing.

- DTF film:it's the surface on which you print your design.

- DTF powder:it acts as an adhesive between the inks and the cotton fibers.

- RIP software:necessary to print CMYK and white-colored layers correctly because, as mentioned before, the printer has been modified and wouldn’t be able to print in the correct order by itself.

- Heat press:we recommend a press with an upper platen that lowers vertically to make the DTF film’s curing process easier.

You will know about what I am talking about if you take a try in both the whole processes of sublimation and DTF, no matter how complicated the videos of making DTF T-shirts you were watching before.

The sublimation took me much time in heat pressing, each pressing would be keeping at least 3 minutes, and it’s just 15-30 seconds for DTF, based on both of them needing to print and cut.

Especially, you have to meticulously cut the printout off the paper after sublimation printing which is part of torturing me. Therefore, it is good that the DTF is getting rid of this part, even if the powder shaking is included.

- Printing Restriction

The DTF printers can be applied to print on various textile materials, such as polyester, cotton, jeans, canvas, modal, etc.

The sublimation can only be to cotton actually, then it can also be used for mugs and something hard.

As the sublimation people all know, the ink for it is restricted in CMYK, no W, which means we can only print on light color objects, even only on white items. If I want to print the image of Taylor Swift on a black blank T-shirt by sublimation, she’s going to be a black woman.

However, DTF is really good in this field, the full colors CMYKW are applied. You can print all the designs on any color garments.

The white people are white while black is black.

- Waterproof

You can not imagine how washable the DTF prints are, I got a couple of DTF T-shirts this summer, then there is no color drop after about 50 times washing for each. It is amazing.

But the sublimation does not perform well in this, the sublimation T-shirts I have started color drop even after only one washing. Even if we can print on mugs, wood, or else by sublimation.

Who would be fond of the non-bright color shirts or something?

- Pattern Size

That is the biggest difference between sublimation and DTF.

Sublimation is more inclined to make small-size prints, like mug designs and small T-shirt logos, the biggest pattern is for A4 size.

DTF can make larger-size design even A1, although it can only print on garments.

Is DTF printing what you’re looking for?

DTF printing is perfect for anyone looking to include T-shirt personalization, or any other textile product (cushion covers, masks, bags, sweatshirts, etc.) into their cotton or polyester business (and their blends of any color), with a low starting investment.

If you're already familiar with dye-sublimation printing, DTF is the perfect complementary technique to increase your performance and make your business even more profitable.

Wow! Looks like we’ve reached the end of this post. What do you think about this new personalization technique? Would you like to include it in your personalization business? You can share your opinion in the comments section.

And don’t hesitate to contact us if you have any further questions about T-shirt personalization and DTF printing. Remember that you can subscribe to our Youtube channel and to our BLOG to keep up to date with the latest news and other interesting information about the world of personalization.