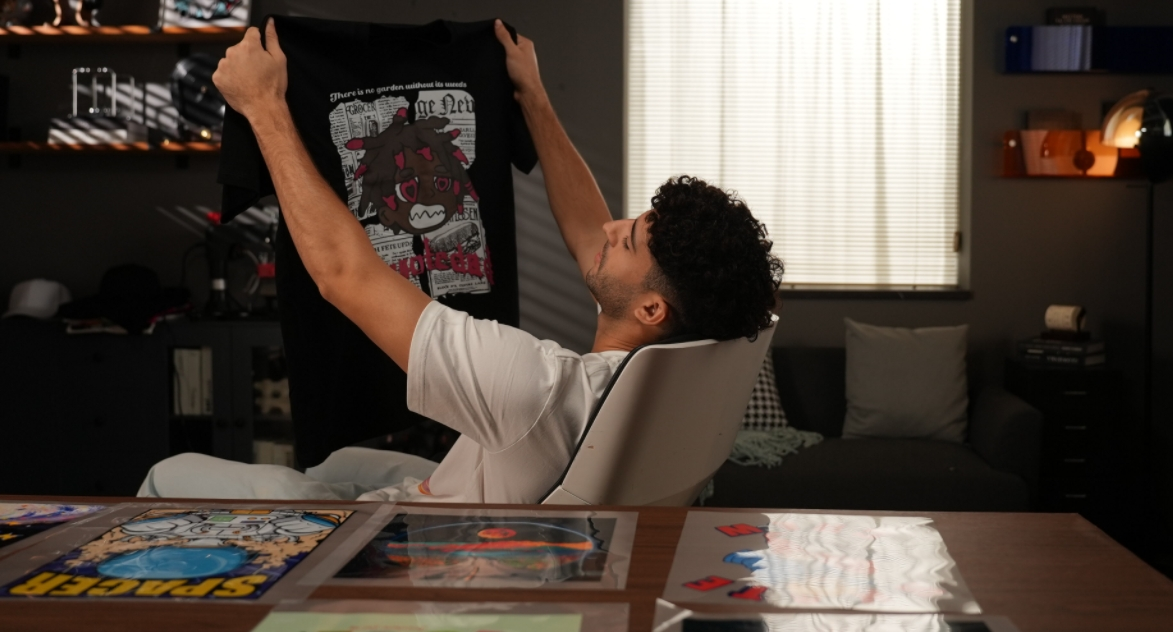

You can have the flashiest artwork and the softest tees, but if you don’t take care of your printer don’t expect great results. Skip the basics and face streaky messes and sad, washed-out colors. Even the fanciest, priciest machine gives you trouble if you ignore the regular upkeep.

Here’s the reality check every shop needs:

● Wipe it down every day.

Yeah, we know, it sounds obvious, but people still skip it. Just grab a cloth and hit the print head and platen—dust, lint, and that weird pretreat sludge love to hide there, just waiting to wreck your next shirt.

● Also, don’t get cheap with the ink.

Those knockoff bottles might look like a steal, but trust me, one bad batch and your printhead’s fail. Not to mention your peace too. Stick with legit DTG ink and thank yourself later.

● Humidity and dust?

Absolute nightmares. If your shop feels like a dusty damp and way too hot, your printer’s gonna age faster. Keep it tidy, keep the temp normal, and suddenly your prints don’t look like a toddler did them.

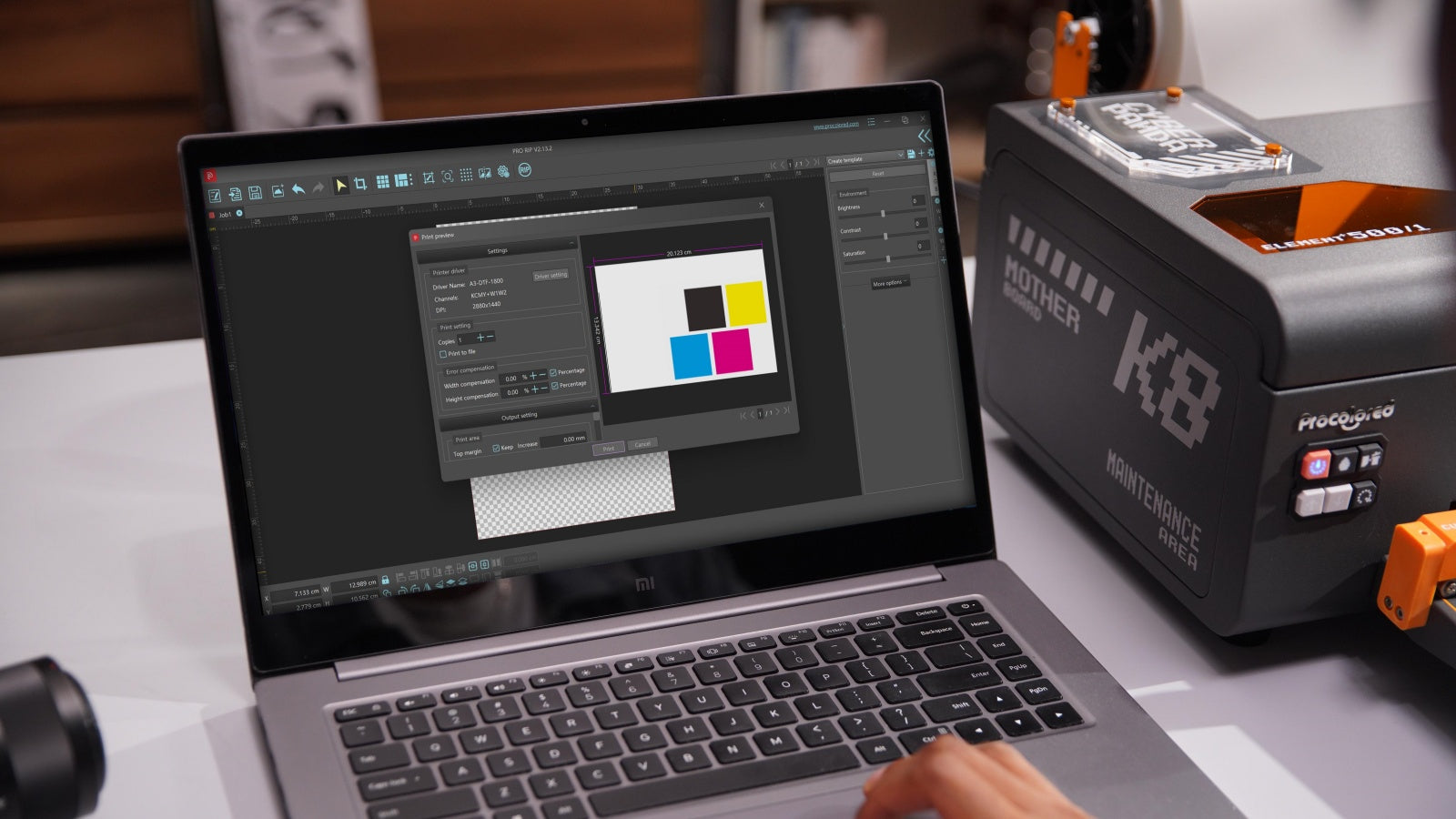

● Always, always run a test print.

Take what, a minute? Saves you from ruining a full batch and your profit margin with it.

●Last thing: the curing station.

If it’s grimy or you’ve got hot spots, you’re basically undoing all your hard work. Just clean it.

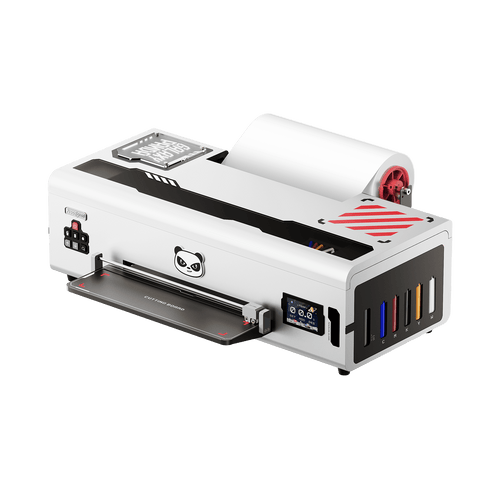

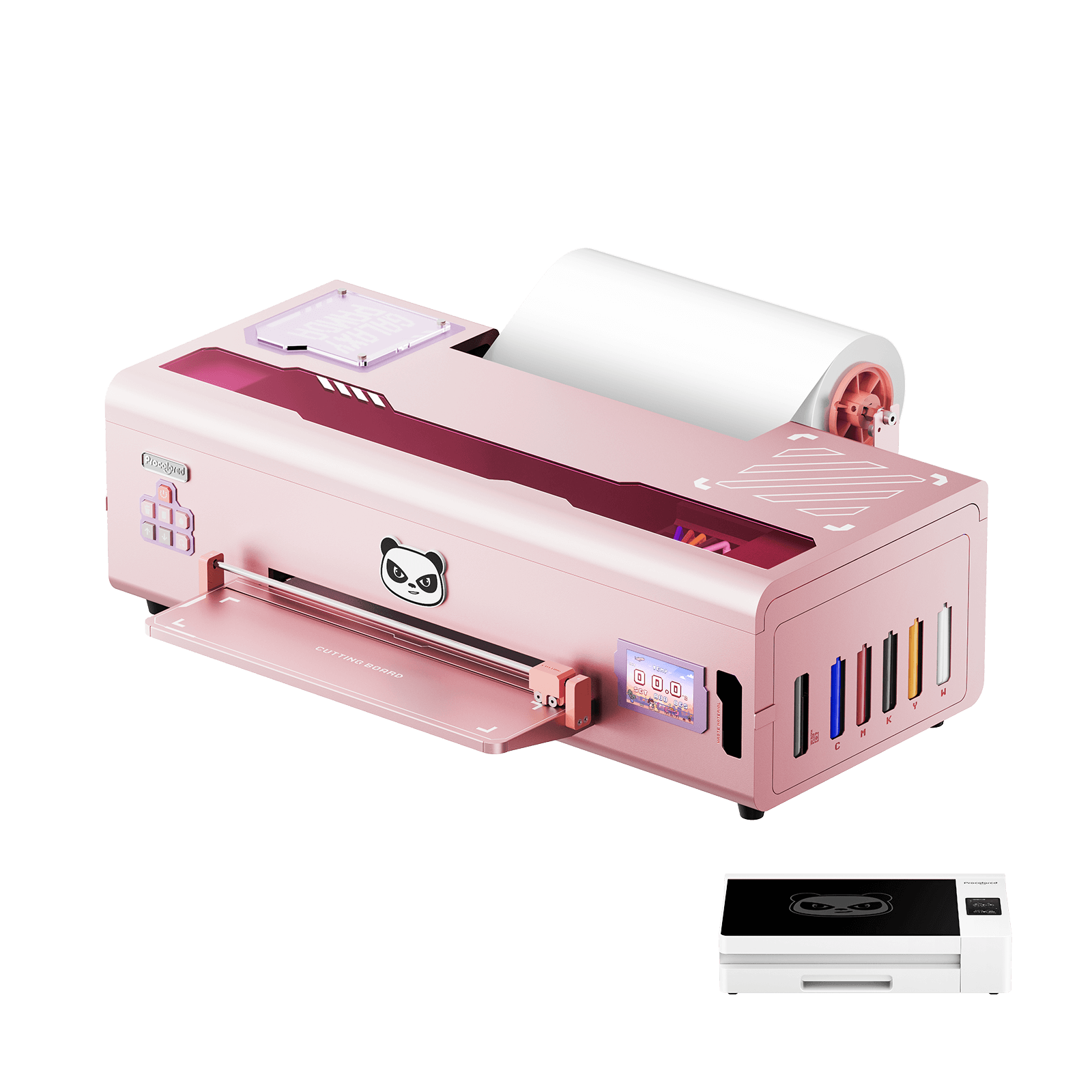

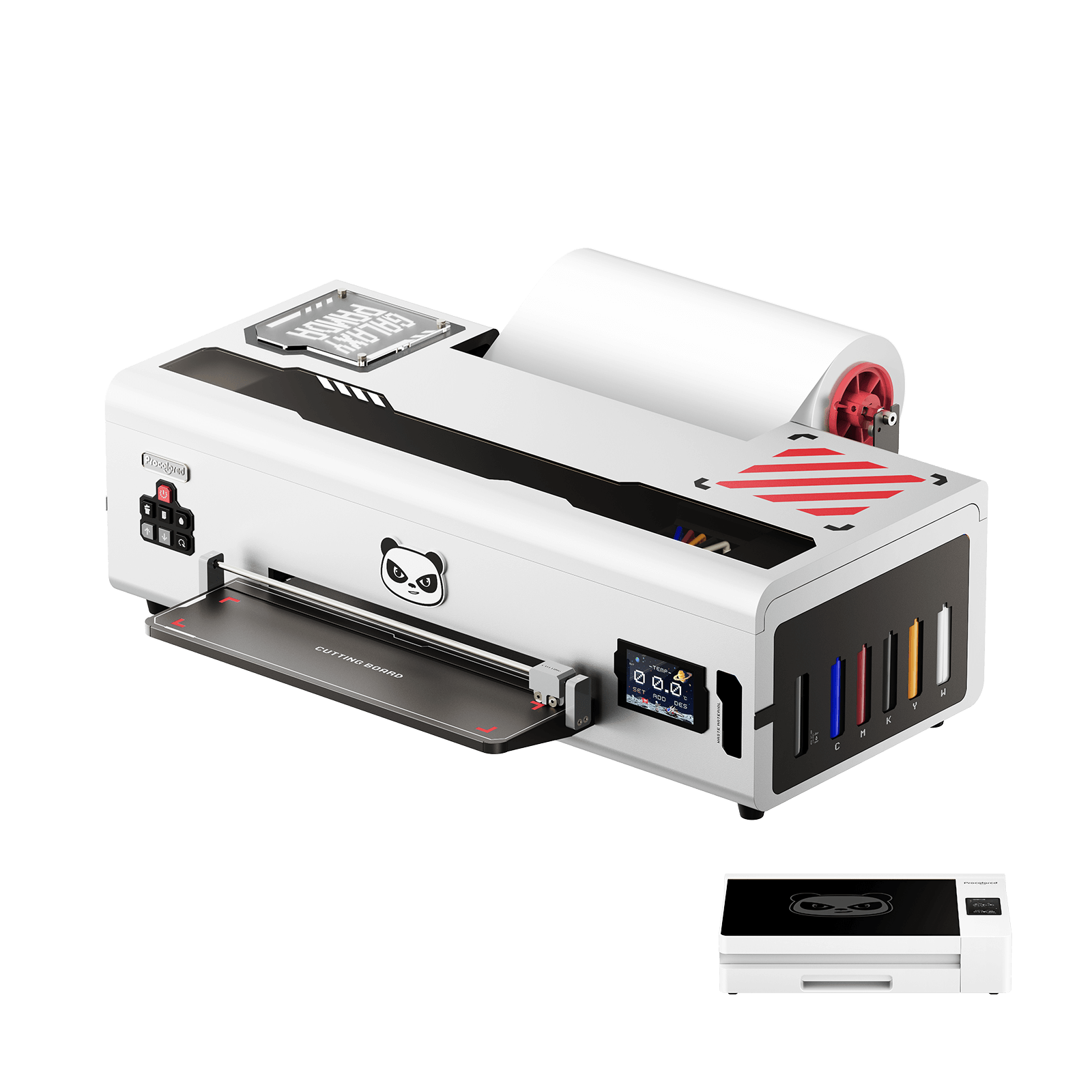

Honestly, Procolored DTG printers make life way easier here. Auto white ink circulation? Emergency stop button? There’s all in-there. No more fighting with clogged nozzles every other day—the machine just keeps going. Less stress, better prints, you win.

Remember:

● Most DTG disasters tend to happen when people just skip on maintenance or let ink turn into concrete.

● And automated cleaning–it cuts downtime by a third.

● So, Treat your printer right, and it’ll last you ages—not just a couple months.

Bottom line: Maintenance isn’t just busywork. It’s what stands between a smooth operation and a total nightmare. Skip it if you’re feeling wild, but don’t say nobody warned you.