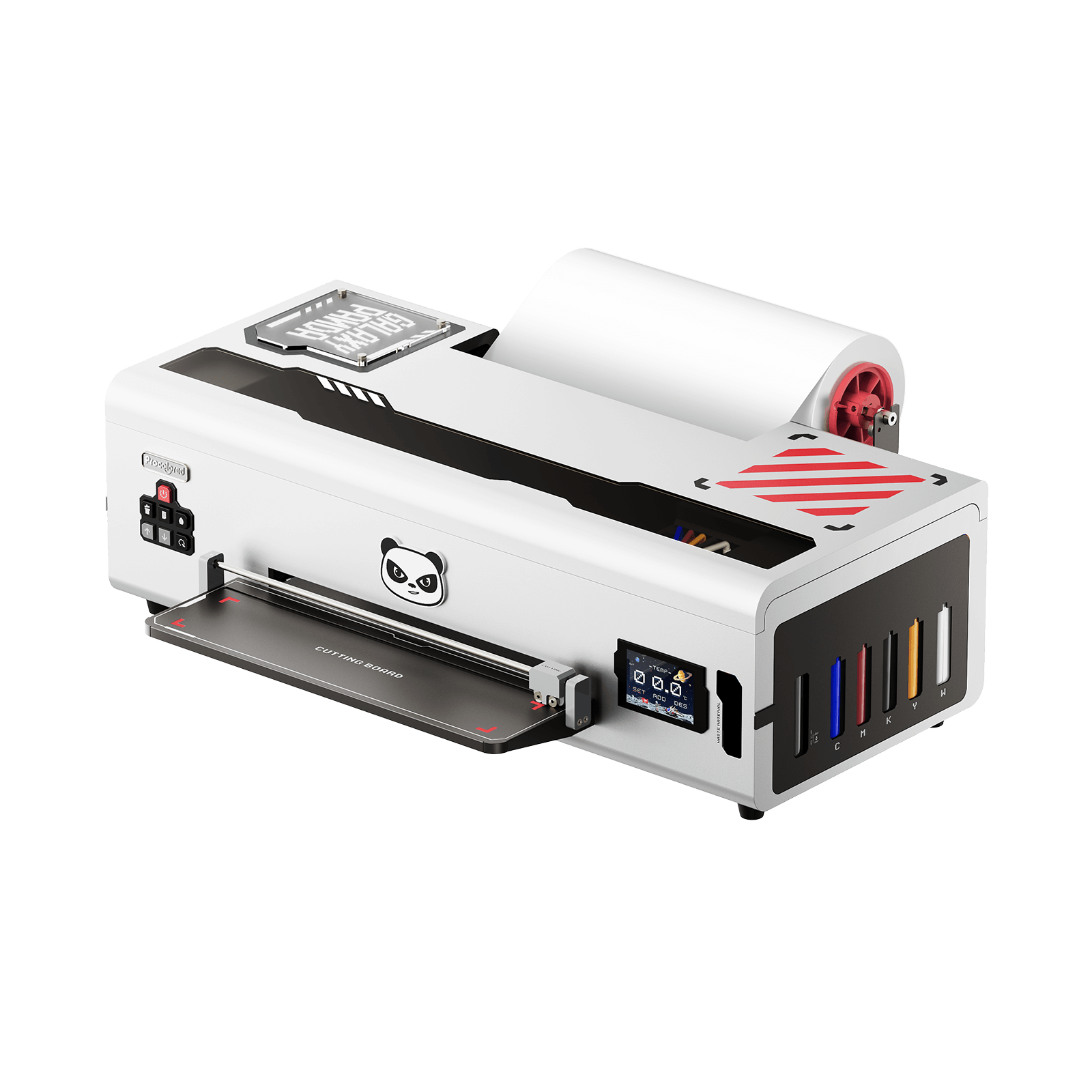

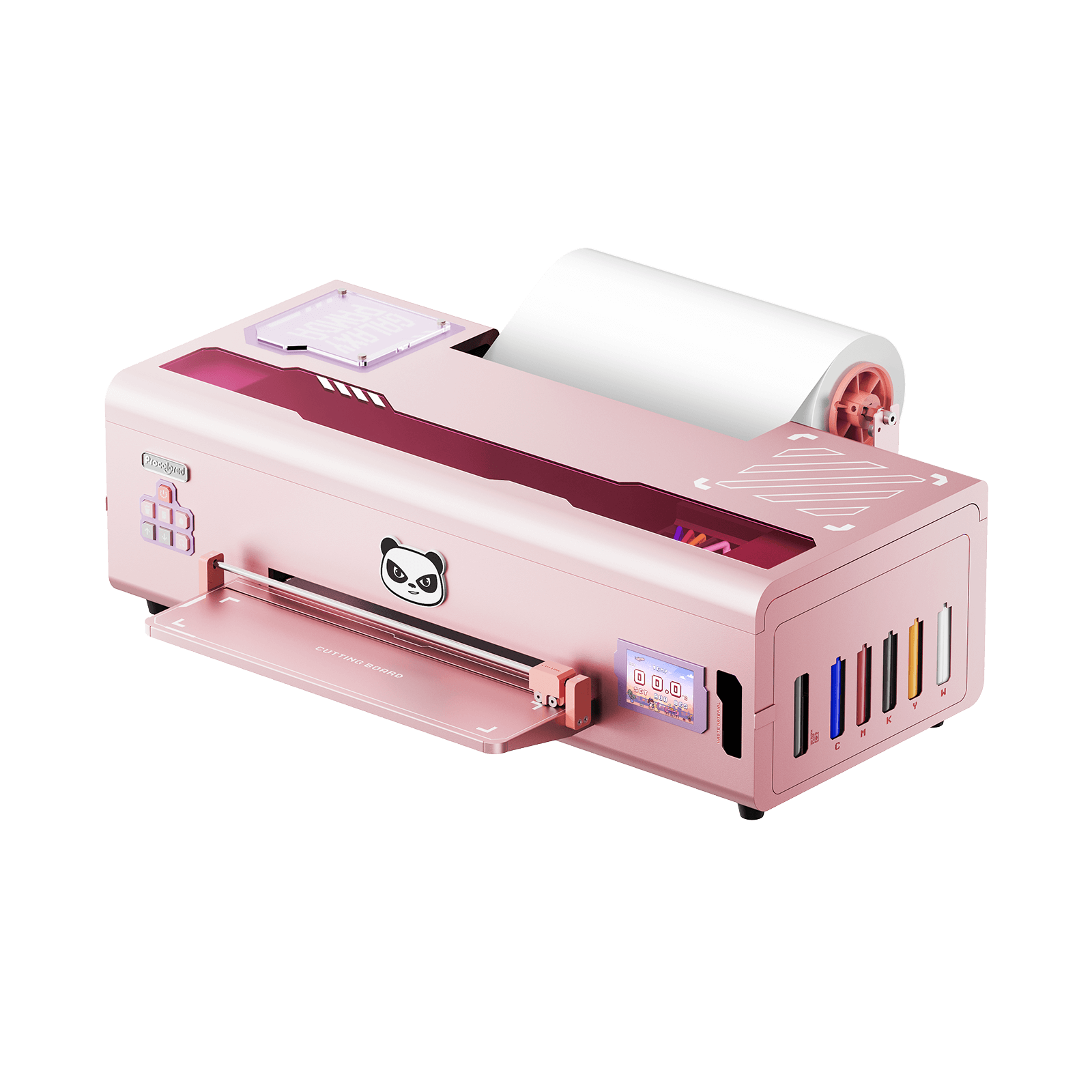

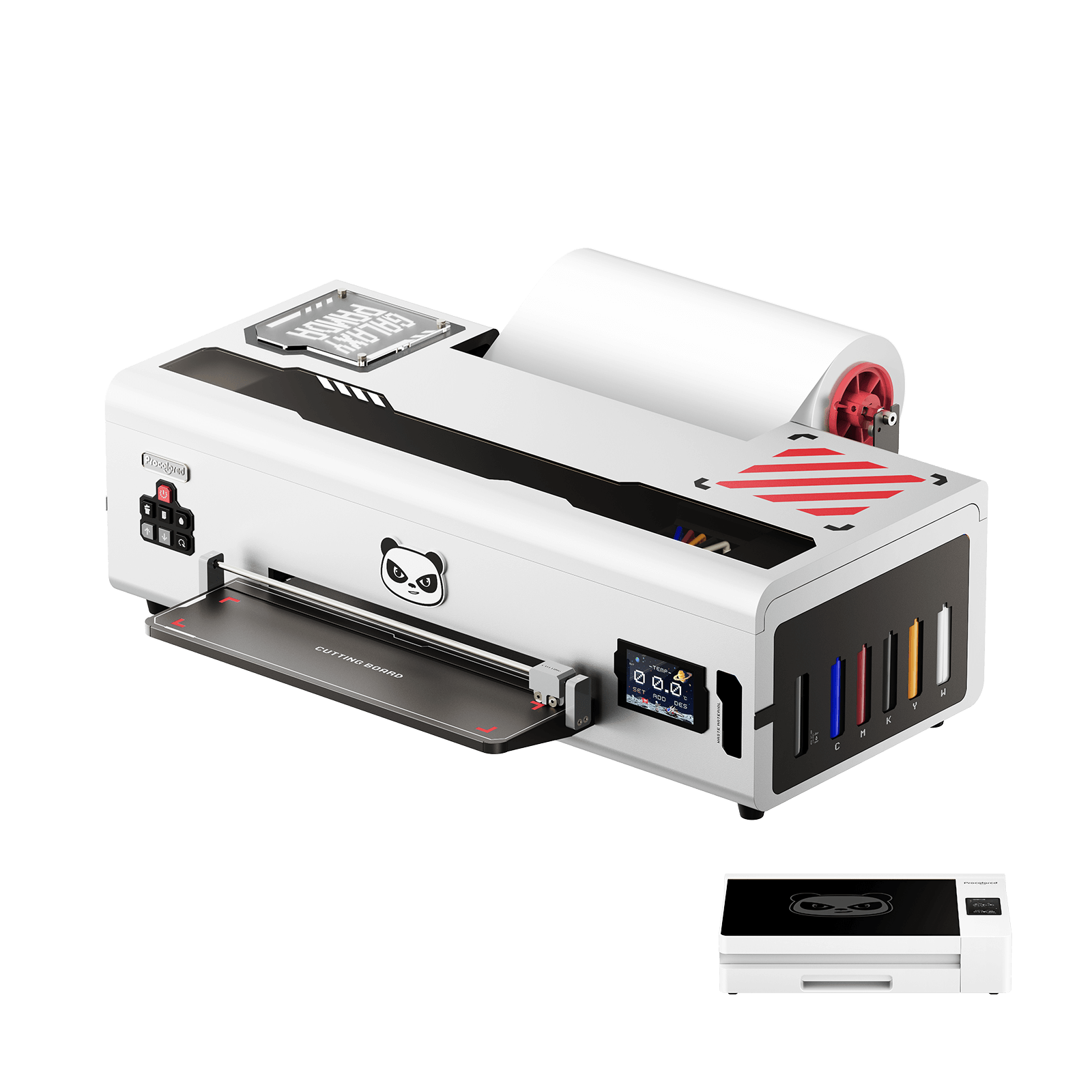

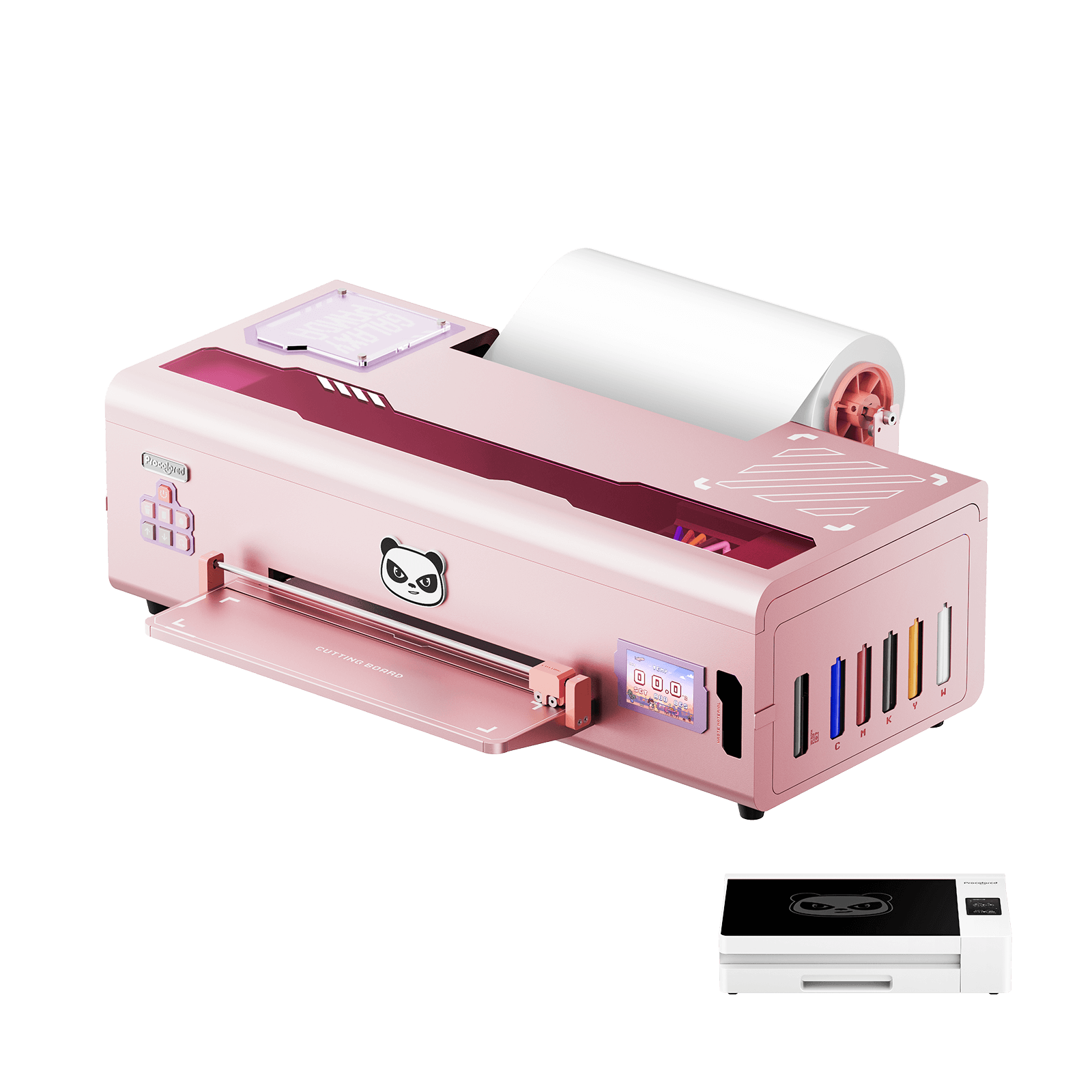

DTF printer, also known as direct to film printer, applies DTF ink and DTF film to produce high-quality direct to film transfers that can be applied to a wide range of fabric, including cotton, polyester, cotton-polyester blends, spandex, nylon, denim, canvas and so forth.

Configured with patented Procolored Siphon Circulation System and diversed printable sizes (we recommend A4 DTF printer for new beginners, A3 DTF printer for small studios), Procolored provides the best DTF printer collection with stable and impressive performance to meet your different needs!

Embark on your creation journey with a Procolored DTF transfer printer now, or compare our machines first for a more informed decision-making.

(5-hour Work Day)

DTF Printer

Versatility of DTF printer

Versatility of DTF printer

There is no doubt that DTF printing technology has gradually ardoused attention from T-shirt print-on-demand industry with its high quality, accuracy, flexibility, and convenience. It can be used on a variety of fabrics, including cotton, polyester, blends, and even dark-colored fabrics. It's capable of printing complex, colorful and detailed designs and transferring them in durable and long-lasting quality to fabrics. Compared toother printing methods like DTG printing, it only requires relatively easier operations and lower costs, suitable for smhall businesses and startups.

T-shirt printing industry has become a larger and larger maarket with impressively speedy growth in recent years. Following this

tendency, more and more people nowadays prefer purchassing customized clothes and even begin to seek methods ofproducing

their owns. A DTF machine can be a perfect choice for thisneed of T-shirt customization.

There is no doubt that DTF printing technology has gradually ardoused attention from T-shirt print-on-demand industry with its high quality, accuracy, flexibility, and convenience. It can be used on a variety of fabrics, including cotton, polyester, blends, and even dark-colored fabrics. It's capable of printing complex, colorful and detailed designs and transferring them in durable and long-lasting quality to fabrics. Compared toother printing methods like DTG printing, it only requires relatively easier operations and lower costs, suitable for smhall businesses and startups.

Other main advantages of DTF printing over DTG printing:

FAQs

A DTF (Direct-to-Film) printer prints designs onto a special PET film, which can then be heat-pressed onto fabrics like cotton, polyester, blends, and more.

DTF printers can transfer designs onto a wide range of textiles, including T-shirts, hoodies, bags, and other fabric items. Some surfaces may require pre-treatment.

Unlike DTG, which prints directly on fabric, DTF prints on a film first, then uses adhesive powder and heat press to transfer the design—offering better versatility and broader material compatibility.

Yes—DTF printing typically requires RIP software to prepare and send print files. The software helps you control color, layout, and printer settings.

You’ll need: DTF transfer film, Adhesive (hot-melt) powder, DTF inks compatible with your printer. These consumables should match the printer model for best results.

Choose based on:

- Print size requirements (A4/A3 etc.)

- Production volume

- Budget

Check each model’s specs on the product page to compare.

Yes. With basic training and follow-along tutorials, even beginners can start DTF printing. Learning RIP software and heat press settings is essential for good results.

Regular maintenance includes:

- Cleaning printheads and capping stations

- Running nozzle checks

- Purging and keeping inks fresh

Routine care helps ensure consistent prints and longer printer life.